l

Tolerances of Newly Installed Parts

Thrust directional tolerance between the cylinder and piston skirt

0.008L - 0.047L

I

I

Top ring

! 0.2L - 0.4L

Clearance of piston ring joint

Second ring 0.2L - 0.4L

’ Oil ring

! 0.05L - 0.25L 1

Spare rings

Top ring

0.09OL - 0.135L

Clearance between piston ring Second ring 1 0.06OL - 0.105L

I

Spare rings

Oil ring

O.OlOL-0.065L ,

Inside and

outslde diameter

Clearance between connecting clearance

0.037 L - 0.063L

rod major end and crankpin

I

Side clearance 0.1 L - 0.7L

Clearance between connecting rod minor end and piston pin

O.OlOL - 0.029L

Clearance between piston pin and piston pin hole

0.009T - 0.01 OL

L = Loose T = Tight

Table 12-2

NOTE: The clearance between the piston and cylinder is checked by measuring the clearance between the piston and

cylinder skirt.

124-3 PISTON and PISTON RINGS

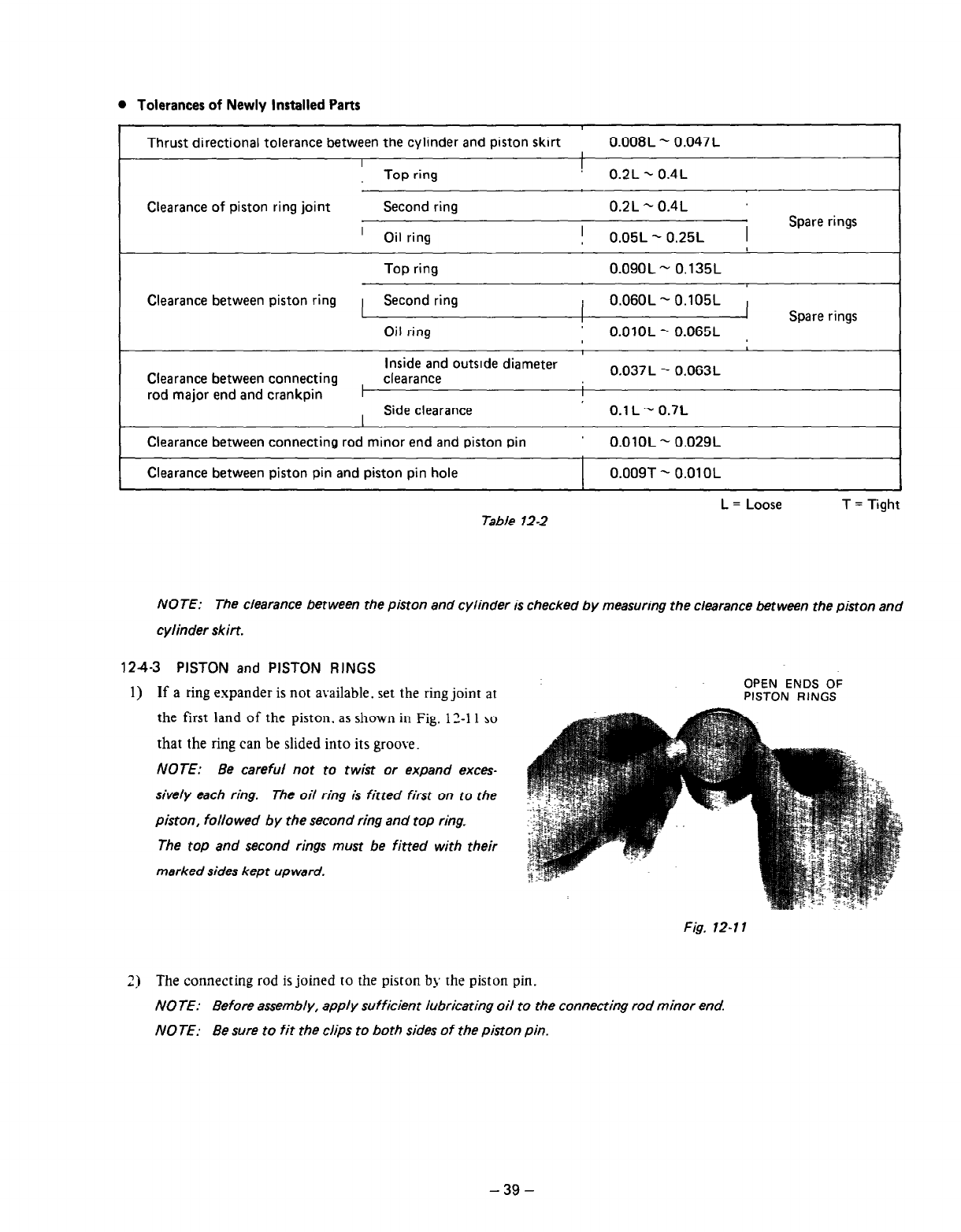

1) If a ring expander is not available. set the ring joint at

OPEN ENDS OF

PISTON RINGS

the first land of the piston. as shown in Fig. 12-l 1 so

that the ring can be slided into its groove.

NOTE: Be careful not to twist or expand exces-

sively each ring. The oil ring is fitted first on to the

piston, followed by the second ring and top ring-

The

top

and second rings must be fitted with their

marked sides kept upward.

Fig. 12-l 1

~j The connecting rod is joined to the piston by the piston pin.

NOTE: Before assembly, apply sufficient lubricating oil to the connecting rod minor end

NO JE: Be sure to fit the clips to both sides of the piston pin.

-39-