12-4 ASSEMBLY PROCEDURE

0 Precautions in Assembly

1) Thoroughly clean each part. When cleaning. take special care for the piston. cylinder, crankshaft, connecting rod, and

bearings.

7) Be

sure to completely remove the carbon deposits on the cylinder head and piston head. Also, thoroughly clean and

remove carbon deposits from each piston ring groove.

3) Apply lubricating oil to the lip of each seal. Confirm that the lip of each oil seal is not damaged. If damaged, replace

with new one.

4)

Replace the gaskets and similar items with new ones; do not reuse old gaskets.

5) Replace the keys. pins, bolts, nuts. etc., with new ones if necessary.

6) Do not apply torque exceeding the specified value.

7) Apply lubricating oil to both moving and sliding parts when they are assembled.

8)

Prior to assembly, check the clearance of each part, and adjust it if necessary.

9) When each of the main components are assembled, turn it by hand to check for smoothness of rotation and unusual

noise.

l

Assembly Sequence and Precautions

12-4-l GOVERNOR SHAFT

Put the governor shaft into crankcase, then drive the clip into position to secure the governor shaft.

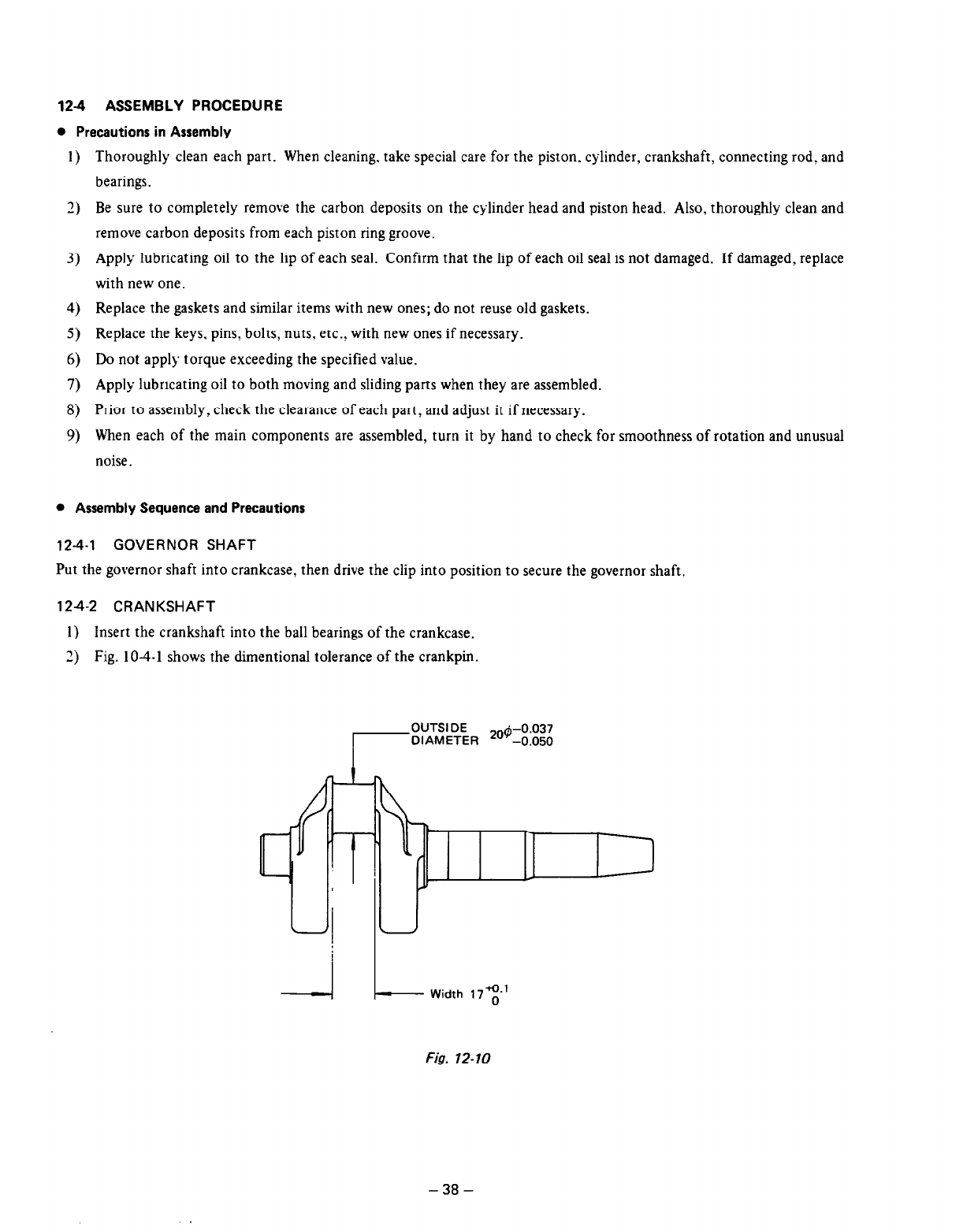

124-2 CRANKSHAFT

1) Insert the crankshaft into the ball bearings of the crankcase.

2)

Fig. 104-l shows the dimentional tolerance of the crankpin.

OUTSI DE

-DIAMETER

Fig. 72-10

-38-