54

Section 5: Maintenance & Lubrication

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11/11/12

Table of Contents

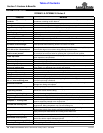

CV Main Driveline Joints & Shields

CV = Constant Velocity

Type of Lubrication: Multi-purpose Grease

For instructions on how to access grease zerks shown

in Figure 5-16, see “Accessing CV Driveline Joints”

on page 55.

• The constant velocity joint should be greased in a

straight position forcing grease through the passages

and into the cavity. After lubrication, grease should

be visible around the ball joints.

• Grease fittings located on the u-joints and driveline

shields should be lubricated every 8 hours of

operation.

IMPORTANT: To extend the life of the constant

velocity joint, extensive lubrication must be

performed every 8 hours of operation.

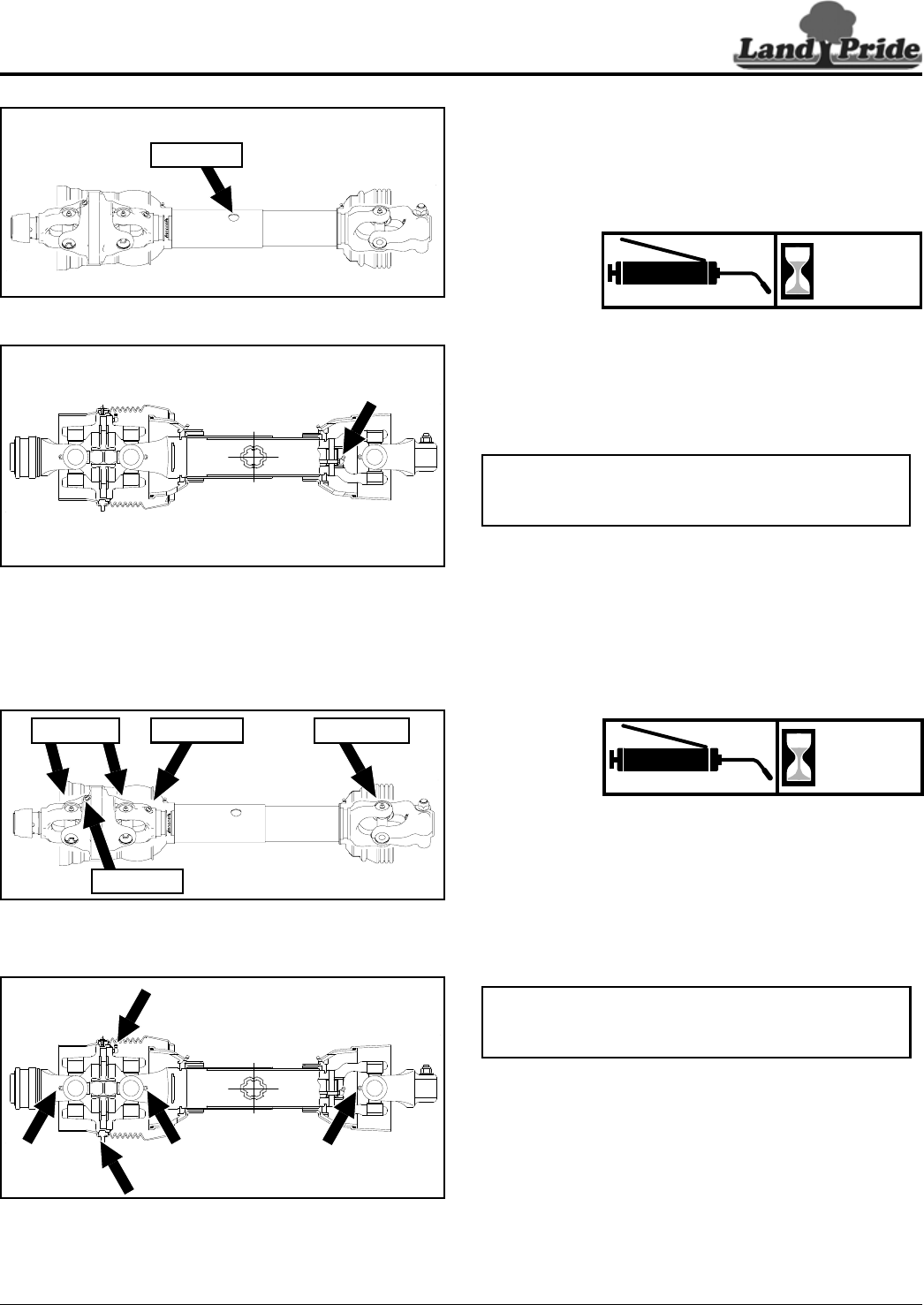

CV Main Driveline Profile Tubes

CV = Constant Velocity

Type of Lubrication: Multi-purpose Grease

Quantity = Coat Generously

IMPORTANT: To extend the life of the constant

velocity joint, the grease zerk for the profile tubes

must be lubricated every 8 hours.

8

Hours

8

Hours

CV Drivelines with external grease point for Profile Tube

CV Drivelines with internal grease point for Profile Tube

23556

8-10 pumps

Zerk Located through slot in tube

23565

Zerk Located on end of tube

CV Drivelines with external grease point for Profile Tube

Figure 5-16

CV Drivelines with internal grease point for Profile Tube

Figure 5-17

23556

4-5 pumps

2-3 pumps 2-3 pumps

4-6 pumps

23565

Access Zerk through hole in shield