42

Section 5: Maintenance & Lubrication

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11/11/12

Table of Contents

Cutter Blade Maintenance

!

DANGER

Always disconnect main driveline from tractor PTO before

servicing underside of cutter. PTO can be engaged if tractor is

started causing cutter damage, bodily injury or death.

!

DANGER

Always secure cutter deck in the up position with solid

supports before servicing underside of cutter. Never work

under equipment supported by hydraulics. Hydraulics can

drop equipment if controls are actuated or if hydraulic lines

burst. Either situation can drop the cutter instantly even when

power to the hydraulics is shut off.

!

WARNING

Do not operate cutter with blades that are bent, out-of-

balance, excessively worn, excessively nicked, or with blade

bolts that are excessively worn. Such blades can break loose

from the cutter at high speeds causing serious injury or death.

!

WARNING

Wait for blades to come to a complete stop before accessing

blade bolts through blade bolt access hole.

!

WARNING

Do not attempt to straighten a bent blade or weld on a blade.

Do not attempt to modify a blade such as hard surfacing, heat

treating, cold treating, or by any other method. Always

replace blades with a new Land Pride blade to assure safety.

!

CAUTION

ALWAYS wear gloves and eye protection while inspecting,

removing, sharpening, and replacing cutter blades.

Always inspect cutting blades before each use. Make

certain they are properly installed and in good working

condition. Replace any blade that is damaged, worn,

bent, or excessively nicked. Never try to straighten a bent

blade! Small nicks can be ground out when sharpening.

Refer to Figure 5-6 on page 42 when ordering Land Pride

replacement blade components.

Remove cutting blades and sharpen or replace as

follows:

1. Place tractor gear selector in park or set brake, shut

engine off and remove ignition key.

IMPORTANT: Replace cutting blades with genuine

Land Pride blades only. Blades must be replaced in

mating pairs. Not replacing both blades will result in

an out-of-balance condition that will contribute to

premature bearing breakdown on the spindle hub

and create structural cracks in the cutter housing.

2. Disconnect main driveline from tractor PTO and

secure cutter deck in the up position with solid

supports before servicing underside of cutter.

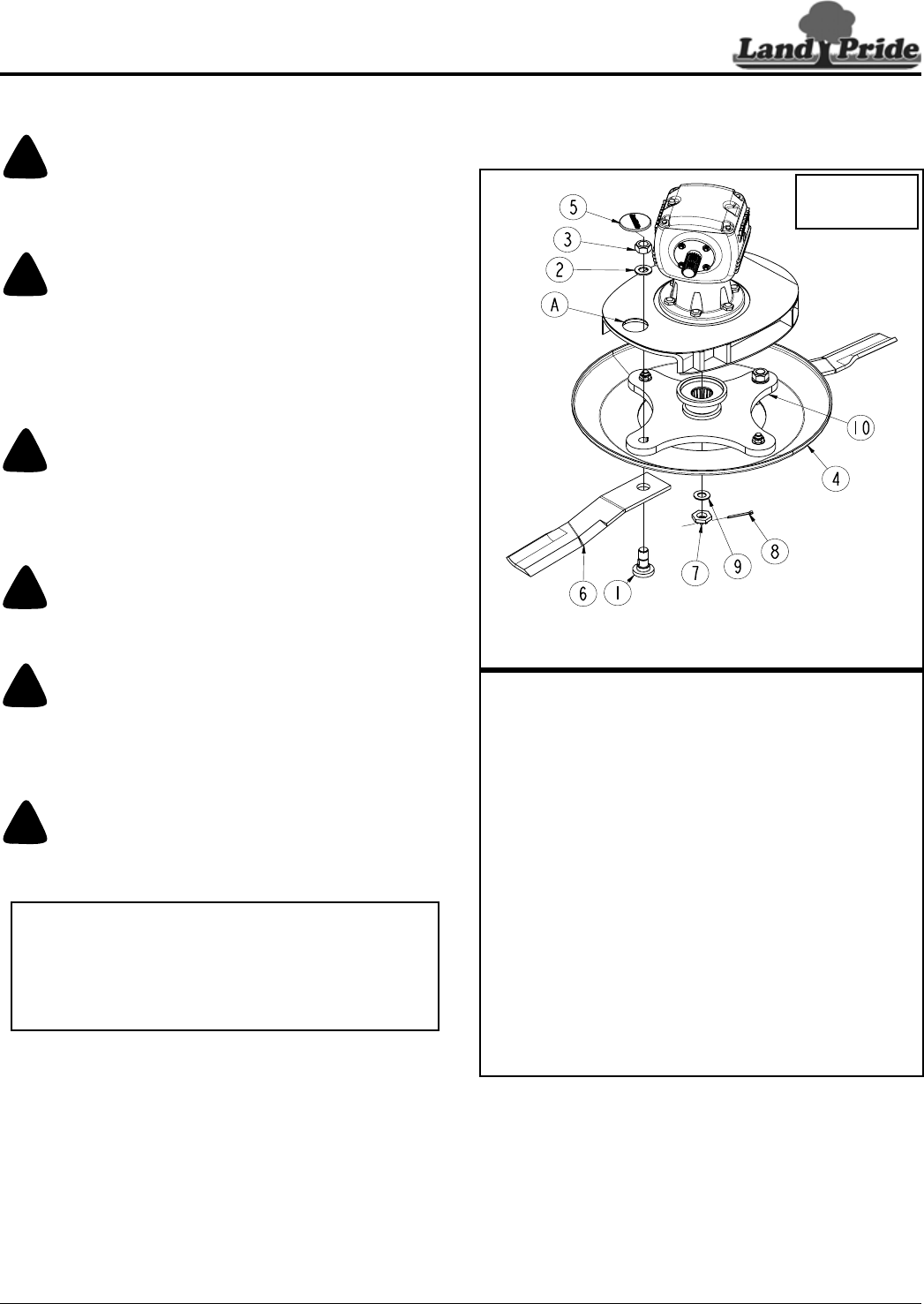

Cutter Blade Assembly (Standard Blade Rotation Shown)

Figure 5-6

Refer to Figure 5-6:

3. Remove rubber plug (#5) above cutter blade (#6).

Rotate blade bolt (#1) until in alignment with access

hole (A).

4. Unscrew lock nut (#3) to remove cutting blade (#6).

Blade bolt (#1) is keyed and will not turn freely.

30236

Use 1-11/16"

Socket Wrench

On Blade Nut #3

Blade Bolt Kit & Dishpan Part No’s.

Item Part No. Part Description

318-586A BLADE BOLT KIT (Item No’s 1, 2, & 3)

)

1 802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

2 804-147C WASHER FLAT 1 HARD ASTMF436

3 803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

4 318-766H WELDMENT DISHPAN

5 840-273C PLUG LP 3" ID RUBBER

Standard Blades, Standard Rotation

6 820-168C CUTTER BLADE 1/2 x 4 x 29 CCW (Deck)

6 820-169C CUTTER BLADE 1/2 x 4 x 23 CCW (Wing)

Standard Blades, Special Reverse Rotation

6 820-249C CUTTER BLADE 1/2 x 4 x 29 CW (Deck)

6 820-170C CUTTER BLADE 1/2 x 4 x 23 CW (Wing)

Accessory Blades*

Low Lift Blades, Standard Rotation

6 820-478C CUTTER BLADE 1/2X4X29 LL CCW (Deck)

6 820-479C CUTTER BLADE 1/2X4X23 LL CCW (Wing)

*For additional information, see

“Low Lift Blade

Accessory”

on page 39