23

Section 1: Assembly & Set-up

11/11/12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

Table of Contents

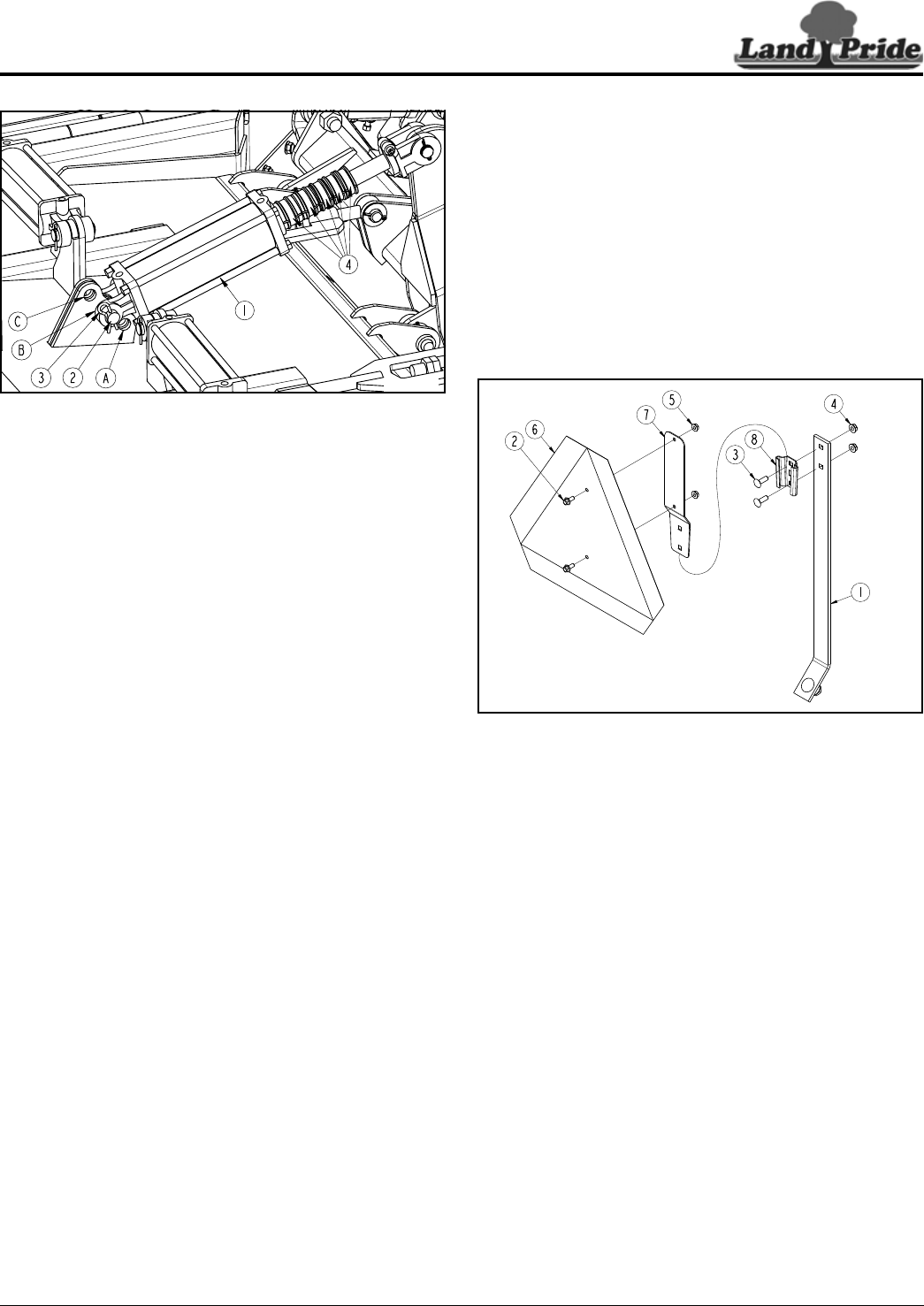

Lift Cylinder Mounting Position

Figure 1-21

Lift Cylinder Mounting Position

Refer to Figure 1-21:

Lift cylinder (#1) should be mounted in lower hole (A) if

cutter is equipped with 21" laminated tires or middle

hole (B) if cutter is supplied with 25.5" aircraft tires, or

upper hole (C) if 29" aircraft tires. Reposition lift cylinder

if it is not assembled in the correct hole.

1. Park tractor and cutter on a level surface and raise

center deck fully up.

2. Without lowering cutter, shut tractor down properly

before dismounting. Refer to “Tractor Shutdown

Procedure” on page 14.

3. Place sturdy support blocks or jack stands under the

four corners of the center deck.

4. Remove all stroke control spacers (#4) from the

hydraulic cylinder rod.

5. Start tractor and lower center deck onto the support

blocks until hydraulic cylinder hitch pin (#2) is loose.

6. Shut tractor down properly before dismounting.

7. Remove hairpin cotter (#3) and hitch pin (#2).

8. Reposition hydraulic cylinder to the correct mounting

hole (A, B, or C) and reinsert hitch pin (#2). Secure

hitch pin with hairpin cotter (#3).

9. Start tractor, raise deck fully up, and then shut tractor

down again before dismounting.

10. Replace stroke control spacers (#4) and remove

support blocks.

11. Start tractor and cycle hydraulic system by raising

and lowering center deck cylinder and wing folding

cylinders.

26611

26611

Rephase Lift Cylinders

The lift cylinders may be out of phase. See “Rephasing

Lift Cylinders” on page 34 for detailed instructions.

Slow Moving Vehicle Sign (SMV)

Refer to Figure 1-22:

Mounting blade (#7) is shipped from the factory bolted to

mounting socket (#8). The two should be separated and

reassembled as follows:

1. Remove hex flange nuts (#5), hex flange serrated

screws (#2) and SMV sign (#6) from mounting

blade (#7). Keep hardware for reuse.

SMV Sign Assembly

Figure 1-22

2. Remove hex whiz nuts (#4), carriage bolts (#3),

mounting blade (#7), and mounting socket (#8) from

bracket (#1). Keep hardware for reuse.

3. Attach mounting socket (#8) to bracket (#1) with

existing carriage bolts (#3) and hex whiz nuts (#4).

Tighten whiz nuts to the correct torque.

4. Attach SMV sign (#6) to mounting blade (#7) with

existing hex flange serrated screws (#2) and hex

flange nuts (#5). Tighten nuts to the correct torque.

5. Insert mounting blade (#7) into mounting socket (#8).

30727