43

Section 5: Maintenance & Lubrication

11/11/12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

Table of Contents

5. Both blades should be sharpened at the same angle

as the original cutting edge and must be replaced or

re-ground at the same time to maintain proper

balance in the cutting unit. The following precautions

should be taken when sharpening blades:

a. Do not remove more material than necessary.

b. Do not heat and pound out a cutting edge.

c. Do not grind blades to a razor edge. Leave a blunt

cutting edge approximately 1/16" thick.

d. Always grind cutting edge so end of blade remains

square to cutting edge and not rounded.

e. Do not sharpen back side of blade.

f. Both blades should weigh the same with not more

than 1 1/2 oz. difference. Unbalanced blades will

cause excessive vibration which can damage

gearbox bearings and create structural cracks.

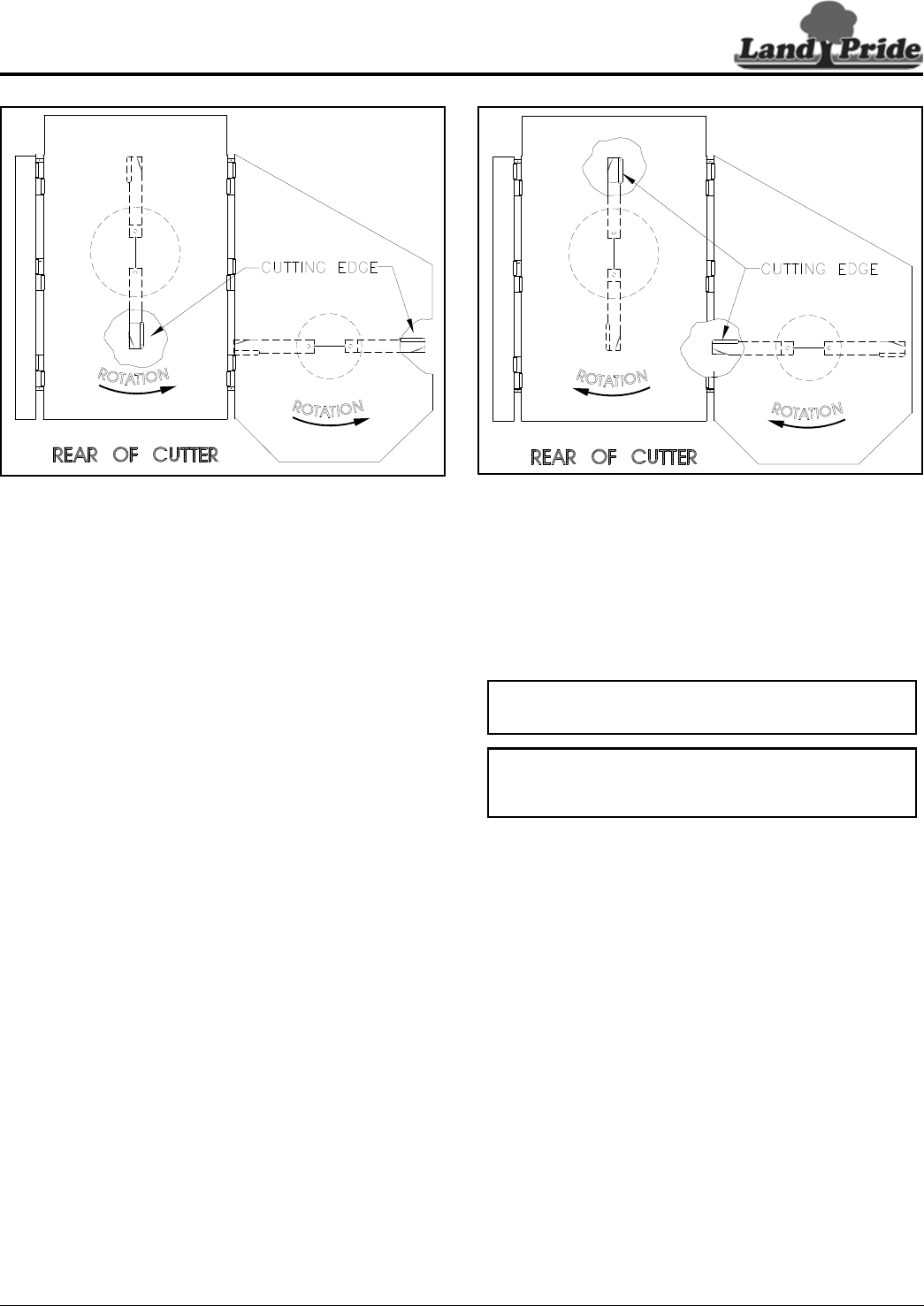

Refer to Figure 5-7 & Figure 5-8:

6. Carefully check cutting edges of blades in relation to

blade carrier rotation to ensure correct blade

placement. Cutter blades must be installed with

cutting edge leading in rotation.

Refer to Figure 5-6 on page 42:

7. Insert blade bolt (#1) through blade (#6),

dishpan (#4), and flat washer (#2). Secure blade with

a new lock nut (#3) and torque to 450 ft-lbs.

8. If replacing RC56 Series dishpan (#4) or RC66

Series blade bar (#10), nut (#7) on gearbox output

shaft should be torqued to 550 ft-lbs. minimum and

secured with cotter pin (#8) with both legs bent

opposite directions around the nut.

9. Replace rubber plug (#5).

10. Reconnect main driveline to tractor PTO shaft and

remove support blocks.

IMPORTANT: Examine blade bolts and their flat

washers for excessive wear and replace if worn.

IMPORTANT: Locknuts can lose their ability to lock

properly once removed. Always use a new locknut

when installing blades.

Standard Blade Rotation

Figure 5-7

Special Reverse Blade Rotation

Figure 5-8

CCW

CCW

27590

CW

CW

30247