52

Section 5: Maintenance & Lubrication

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11/11/12

Table of Contents

23603

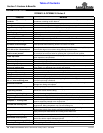

Oil Fill/Vent Plug

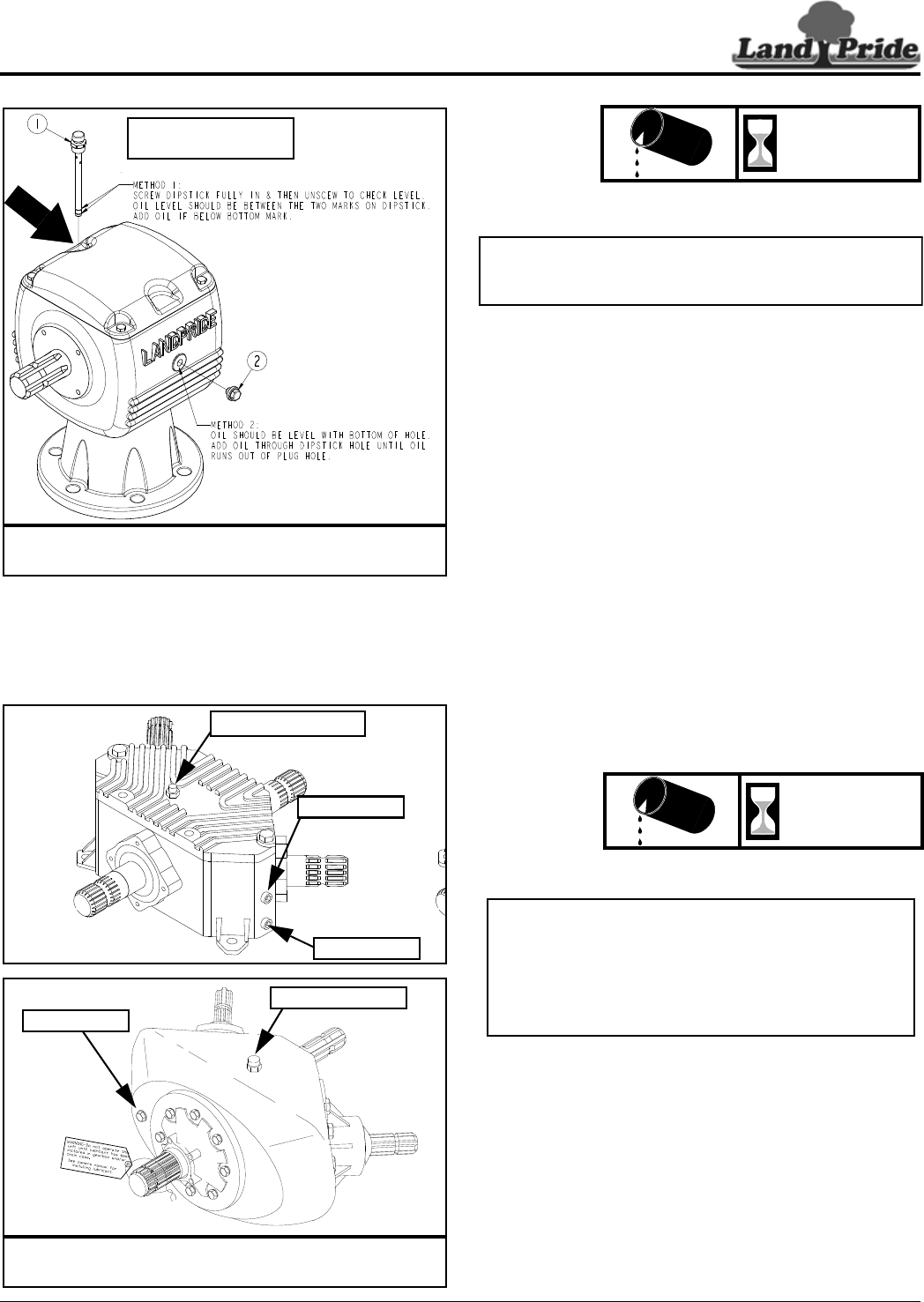

Oil Level Plug

Oil Drain Plug

24852

Oil Level Plug

Oil Fill/Vent Plug

NOTE: Use a suction or siphon pump to drain gearbox

of oil when there is not an oil drain plug.

30215

Do Not Overfill

NOTE: Use a suction or siphon pump to drain gearbox

of oil when there is not an oil drain plug.

8

Hours

8

Hours

Gearbox

Method 1: Unscrew top vented dipstick (#1). Wipe oil

from dipstick and screw dipstick in without tightening.

Unscrew dipstick and check oil on dipstick. If below

bottom level mark, add recommended gear lube through

dipstick hole until oil reaches top mark on dipstick.

Reinstall vented dipstick and tighten.

Method 2: Remove side oil plug (#2). If oil is below

bottom of plug hole, add recommended gear lube

through top dipstick hole until oil flows out of side plug

hole. Reinstall and tighten side oil plug (#2) and vented

dipstick (#1).

Type of Lubrication: 80-90W EP Gear Lube

Quantity = Fill until oil reaches top mark on dipstick or

begins to flow out side plug hole in gearbox.

IMPORTANT: Do not overfill gearbox with oil! Oil will

expand when hot! Make sure cutter is level and oil is

cool before checking oil level.

Divider Box

Instructions: Remove oil level plug. If oil is below bottom

of plug hole, add recommended gear lube through oil

fill/vent plug hole until oil flow out of oil level plug hole.

Reinstall and tighten oil level plug and oil fill/vent plug.

Type of Lubrication: 80-90W EP

Quantity = Fill until oil begins to flow out oil level plug hole

in gearbox.

IMPORTANT: Do not overfill gearbox with oil! Oil will

expand when hot! Make sure cutter is level and oil is

cool before checking oil level.

If oil has been removed from the gearbox, refill

gearbox to level plug, allow time for air to bleed up

from the lower cavity, and then recheck.