Section2: Assembly

iMPORTANT: Checkgear oii ievet in both

transmissions after the first 2 hours of

new tiiier operation, then every 30

operating hours thereafter. SeeSection 5

for instructions.

Figure 2=12: Checking oil level on

Power Unit Transmission.

Figure 2o13: Checking oil level on

Tine Attachment Transmission.

STEP 7: Add Motor Oil to Engine

1. Beforeadding motor oii, park thetiller

oil ieveiground. Levelthe engine by

placing asturdy block under thetines or

the tines depth regulator bar.

2. Referto the EngineOwner's ManuaI

provided with your tiiier for detaiiedinfor-

mation on how to add motor oil andfor

motor oil specifications.

IMPORTANT:Two 20 oz. bottles of motor

oii are included with your tiiier. Checkthe

oii ievei as instructed in the Engine

Owner's Manual provided with your tiiier

BEFOREpouring the full amount of each

bottle into the engine.

iMPORTANT:

° Changeengine oil after first 2 hours of

new operation.

. Checkengine oii ieve! every 5 hours of

operation or each use.

STEP 8: Attach Engiee Throttle

Lever and Cable

Forshipping purposes,the throttie cabie,

together with the throttie iever, is wound

around the engine. Carefuiiyunwind the

cable. If the throttle controi iabetis

covered with a clearprotective coating,

peel it off.

To avoid electric shock from a short

circait (electric start tiJJers only), never

allow the throttle cabte to roach the

battery. Route cabte below the battery,

on the outside of the batteryholder.

To attachthethrottle leverand cable:

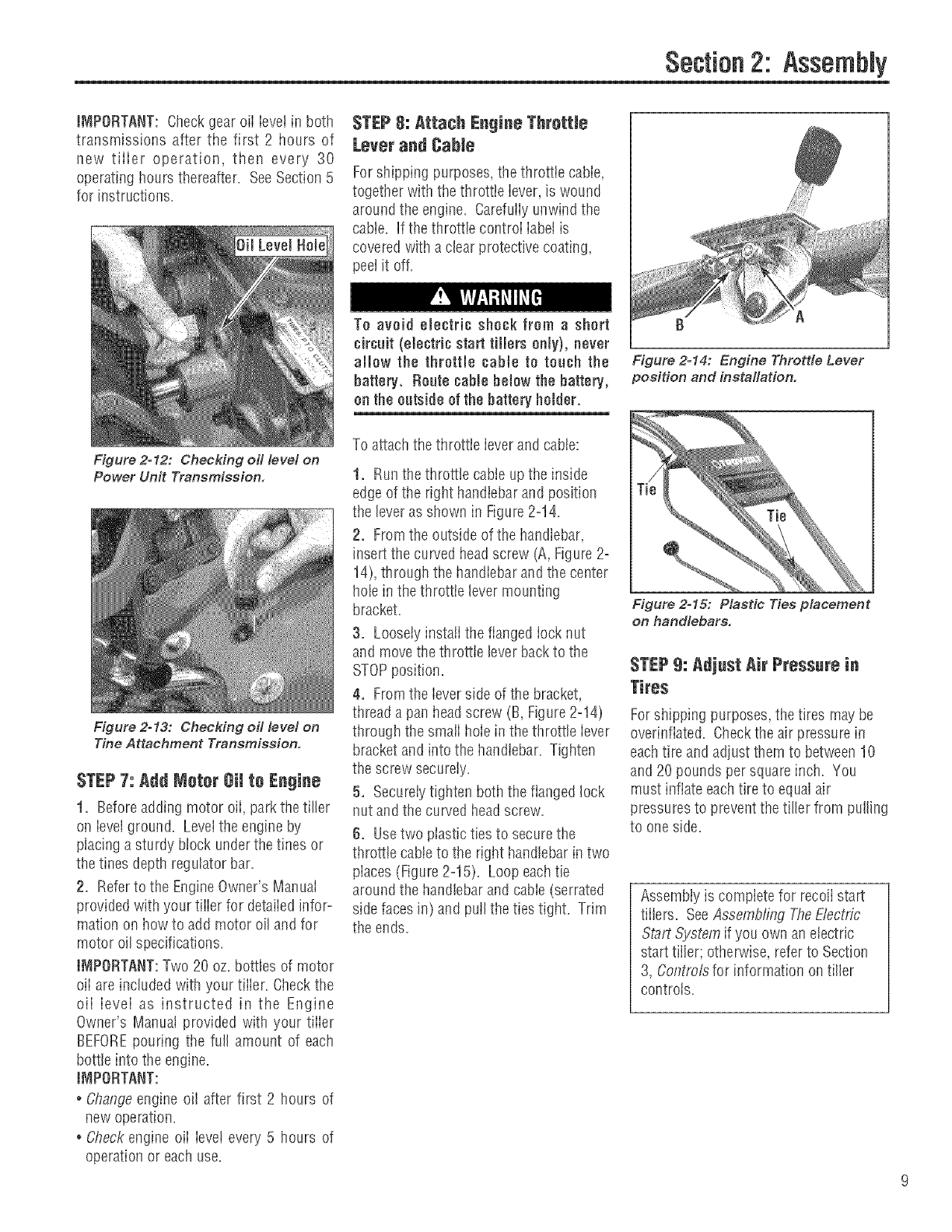

1. Runthe throttle cableup the inside

edge of the right handlebarand position

the leveras shown in Figure2=14.

2. Fromthe outside of the handlebar,

insert the curved headscrew (A,Figure2=

14),through the handlebarand the center

hole in thethrottie levermounting

bracket.

3. Loosely instaii the flanged iock nut

and movethe throttle leverback to the

STOPposition.

4. Fromthe leverside of the bracket,

thread a pall headscrew (B, Figure2=14)

through the smaii hoie in thethrottle iever

bracket and into the handlebar. Tighten

the screw securely.

5. Secureiytighten both theflanged lock

nut and the curved head screw.

6. Usetwo plastic ties to securethe

throttle cableto the right handlebar intwo

places (Figure2=15). Loop eachtie

around the handlebar and cable(serrated

side facesin) and pulIthe ties tight. Trim

the ends.

f} A

Figure 2-14: Engine Throttle Lever

position and installation.

Figure 2o15: Plastic Ties placement

on handlebars.

STEP9: Adjust Air Pressurein

Tires

Forshipping purposes,the tires may be

overinflated. Checkthe air pressure in

eachtire and adjust them to between10

and 20 pounds per squareinch. You

must inflate eachtire to equalair

pressuresto prevent thetiller from pulling

to one side.

Assembiy is compiete for recoiistart

tiilers. SeeAssembling TheElectric

Start System if you own an electric

start tiller; otherwise, refer to Section

3, Controlsfor information oil tiller

controls.