Section5:

Before inspecting,¢meaningor servicing the machine, shut off engine, wait for all moving partsto come

to a ¢ompmetestop, disconnect sparkplug wire and move wire away from spark plug. Remove ignition

key, ifso equipped,

Failure to follow these instructionscan result in serious persenaminjuryor propertydamage.

Tighten Bolts and Nuts

Checkfor loose or missing hardware

every ten (10) operating hours. Failureto

tighten or replacefasteners cancause

poor performance, equipment damageor

oii leakage. Seeyour PartsCataiogfor

complete fastenerdescriptions.

Most hardwareon your tiiier isvisibie.

Payparticuiar attentionto hardware

shown in Figures5-1,5=2, 5=3and 5=3A.

1. Checkthe transmission pulley

mounting bolt (Figure5-1). If the washer

behind the boit headis ioose, the boit

needstiglrtening. To do this, first insert a

punch or thick screwdriver into the hole

next to tire bolt and wedgethe tooi

against the sideof the motor mount

casting. This immobilizes the pulleywhile

you tighten the bolt.

2. Cireckjam nut on ieft side of neutral

plungerassembly(Figure5-2). If loose,

immobiiize bolt headwith onewrench and

useanother wrench to tighten the nut=

3. Checkthe three rear bearingcap

screws underthe depth regulator

mounting bracket (A, Figure5-3). If any

is loose, it cancause an oil leak or drive

shaft end play.

4. Checkthe five bolts securing thetiller

housingcover to the Ieftside of the trans-

mission (B in Figure5-3). Gearoil can

leakfrom a Dose housing cover. To

reachthe boits, removethe ieft side tine

hoider. SeeBnto TineMaintenanceinthis

Sectionfor tine holder removal directions.

5. Checkboth swing-bolts (C, Figure5=3)

that connectthe power unittransmission

to the tine attachment. Both bolts should

becheckedevery 2-1/2 hours of

operation, if ioose, wear canoccur on the

locating pin on tlre power unit, and cause

enlargement of the locating hole in the

tine attachment. Usinga torque wrench,

tighten these bolts to 70-to-80 ft.-ibs.

6. Checkthe iocknut that fastensthe

shifting iinkageto the eccentric shifting

lever (D, Figure5-3). Do not tighten the

Iocknut againstthe eccentric lever, it

should be very closeto, but not touching

the iever.

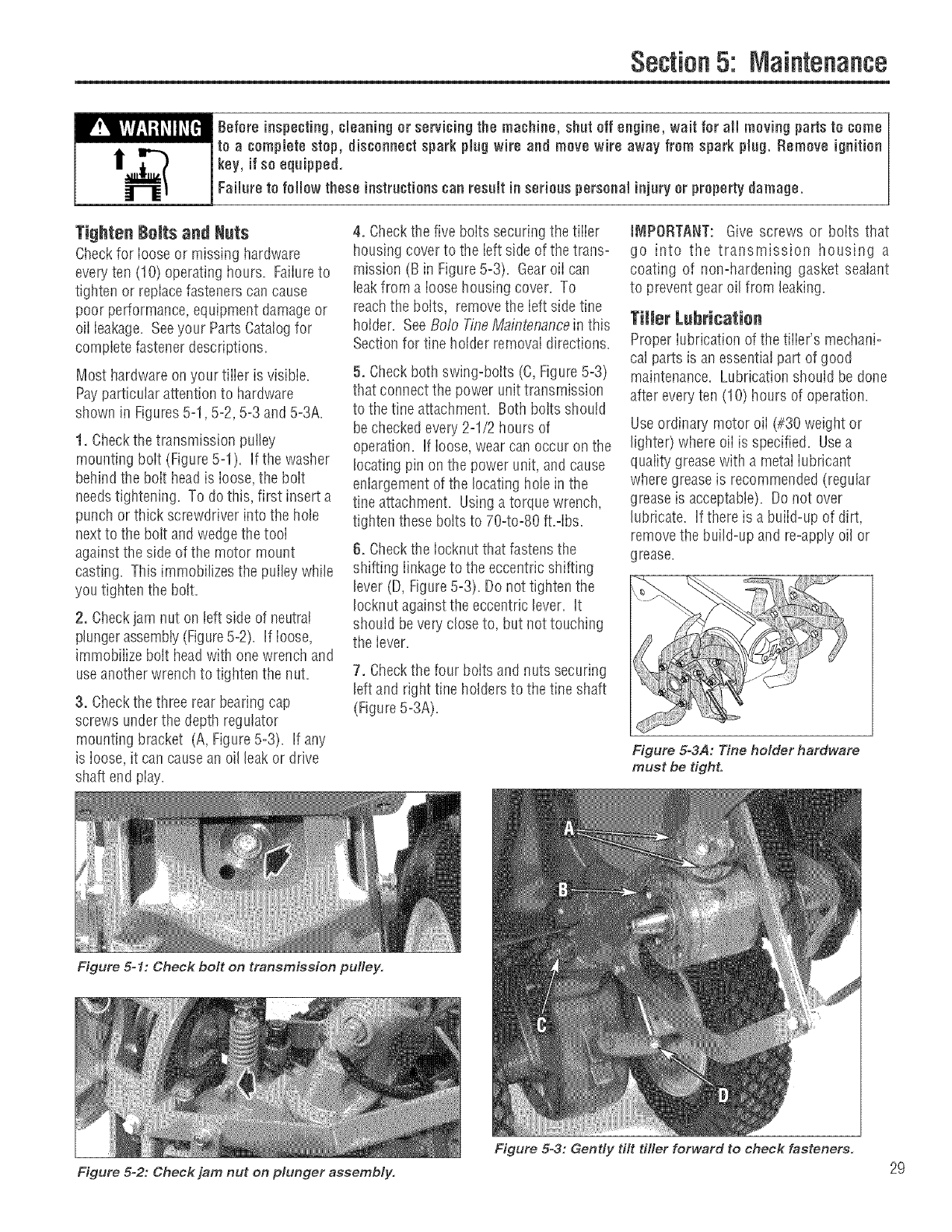

7. Checkthe four bolts and nuts securing

left and right tine holders to the tine shaft

(Figure5-3A).

Figure 5-1: Check bolt on transmission pulley.

JNtPORTANT: Give screws or bolts tlrat

go into the transmission housing a

coating of non=hardening gasket seaiant

to prevent gear oil from leaking.

Tiller Lubrication

Proper lubrication of tire tilIer's rnechani=

cal parts is an essentialpart of good

maintenance. Lubrication should be done

after everyten (1O)hours of operation=

Useordinary motor oii (#30 weight or

lighter) where oii is specified. Usea

quaiity greasewith a metaiiubricant

where greaseis recommended(regular

grease isacceptable)=Do not over

lubricate. If there is a buiid=upof dirt,

removethe build=upand re=applyoil or

gtease=

\ .

Figure 5-3A: Tine holder hardware

must be fight.

Figure 5-3: Gendy tilt filler forward to check fasteners.

Figure 5-2: Check jam nut on plunger assembly. 29