Section5: Maintenance

Before inspecting,cmeaningor servicing the machine, shut off engine,wait for all moving partsto come

to a cempmetestop, disconnect spark plug wire and move wire away from sparkplug. Remove ignition

key, if so equipped,

Failure to follow these instructionscan result in serious personal injuryor property damage.

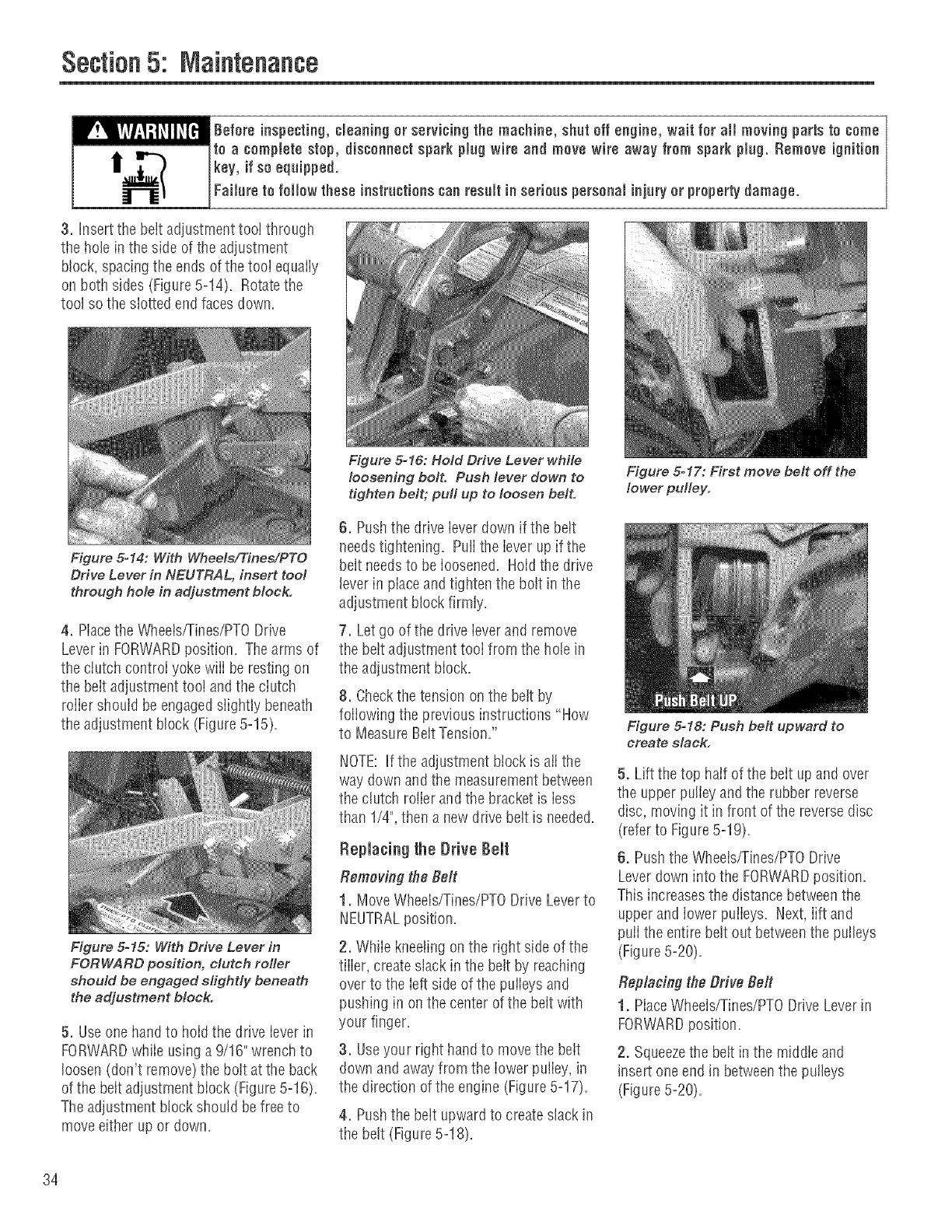

3. Insert the belt adjustment toot through

the hole in the side of the adjustment

block, spacing the ends ofthe tooI equaliy

on both sides (Figure5-14). Rotatethe

tool sothe slotted end facesdown.

Figure 5=14: With Wheels/Tines/PTO

Drive Lever in NEUTRAL, insert tool

through hole in adjustment block.

4. Placethe Wheets/Tines/PTODrive

Leverin FORWARDposition. Thearms of

the clutch controi yoke wiii beresting on

the beit adjustment tooI andthe ciutch

roller should be engagedslightly beneath

the adjustment block (Figure 5o15).

Figure 5o15: With Drive Lever in

FORWARD position, clutch roller

should be engaged slightly beneath

the adjustment block.

5. Useone hand to hold the drive leverin

FORWARDwhiie usinga g/16" wrench to

loosen (don't remove)the bolt atthe back

of the beltadjustment block (Figure5-16).

Theadjustment block should be freeto

moveeither up or down.

Figure 5-16: Hold Drive Lever while

loosening bolt, Push lever down to

tighten belt; pull up to loosen belt.

6. Pushthe drive ieverdown if the beit

needstightening. Puli the iever up if the

belt needsto beloosened. Holdthe drive

leverin piaceandtighten the bolt in the

adjustment block firmly.

7. Letgo of the drive ieverand remove

the beit adjustment tooi from the hole in

the adjustment block.

8. Checkthe tension on the belt by

foiiowing the previous instructions "How

to Measure BeltTension."

NOTE: If the adjustment block is alIthe

way down and the measurementbetween

the clutch rolier andthe bracketis iess

than 1/4",then a newdrive belt is needed.

Replacing the Drive Belt

Removing the Belt

1. Move Wheels/Tines/PTODrive Leverto

NEUTRALposition.

2. Whiie kneelingonthe right side of the

tiiier, createslack in the belt by reaching

overto the ieft side of the puIieysand

pushing in on the center of the beltwith

your finger.

3. Useyour right hand to movethe beit

down and awayfrom the iower puliey, in

the direction ofthe engine (Figure5-17).

4. Pushthe bett upwardto createslack in

the belt (Figure5-18)=

Figure 5-17: First move belt off the

lower pulley.

Figure 5=18: Push belt upward to

create slack.

5. Lift the top half ofthe beit up and over

the upper pulieyand the rubber reverse

disc, moving it in front of the reversedisc

(referto Figure5-19).

6. Pushthe Wheets/Tines/PTODrive

Leverdown into the FORWARDposition.

This increasesthe distancebetweenthe

upperand lower puileys. Next, Iift and

puii the entire belt out betweenthe puileys

(Figure5-20).

Replacing the Drive Belt

1. MaceWheels/Tines/PTODrive Leverin

FORWARDposition.

2. Squeezethe belt in the middie and

insert one end in betweenthe putleys

(Figure5-20).

34