Section5:

Figure 5=19: Move top half of belt

over pulley and reverse disc.

Figure 5=20: Shift into FORWARD

and remove the belt.

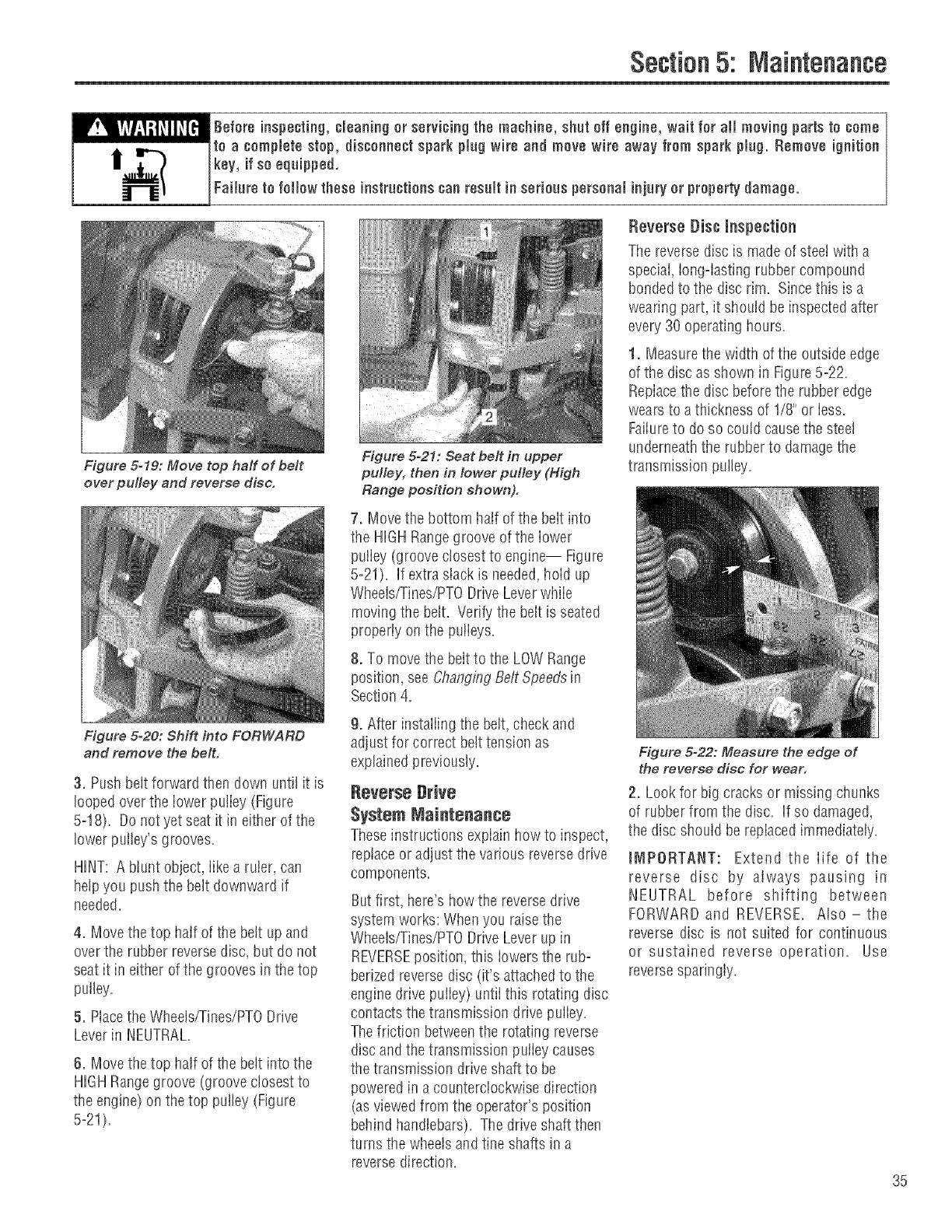

Figure 5=21: Seat belt in upper

pulley, then in lower pulley (High

Range position shown).

Reverse Disc inspection

The reversedisc is madeof steel with a

speciai, iong=iastingrubber compound

bondedto the disc rim= Sincethis is a

wearing part, it shoutd be inspectedafter

every 30 operatinghours=

1. Measurethe width ofthe outside edge

ofthe disc as shown in Figure5=2£

RepIacethe disc beforethe rubber edge

wears to a thickness of 1/8"or iess.

Failureto do so could causethe steel

underneaththe rubber to damagethe

transmission pulley=

7. Move the bottom half ofthe belt into

the HIGHRangegroove ofthe lower

puliey (groove closest to engine-- Figure

5=21). If extra slack is needed,hold up

Wheels/Tines/PTODrive Leverwhile

moving the belt. Verify the belt is seated

properiy on the pulieys.

8. To movethe beltto the LOWRange

position, seeChangingBeltSpeedsin

Section 4.

3. Pushbelt forward then down until it is

looped overthe lower pulley (Figure

5=18). Donot yet seat it in either of the

lower pulley's grooves.

HINT: A blunt object, Iike a ruler, can

help you push the belt downward if

needed.

4. Move thetop hair of the bett up and

overthe rubber reversedisc, but do not

seat it in either ofthe grooves in the top

pulley.

5. Piacethe Wheels/Tines/PTODrive

Leverin NEUTRAL.

6. Move thetop half of the belt into the

HIGHRangegroove (groove closest to

the engine) on thetop pulley (Figure

5-21).

9. After instaliing the belt, check and

adjust for correct belttension as

explainedpreviously.

Reverse Drive

System Maintenance

Theseinstructions expiainhow to inspect,

reptaceor adjust the various reversedrive

components.

Butfirst, here'show the reversedrive

system works: Whenyou raisethe

Wheeb/Tines/PTODrive Leverup in

REVERSEposition, this iowers the rub°

berizedreverse disc (it's attachedto the

engine drive puiiey) untii this rotating disc

contactsthe transmission drive puiiey.

Thefriction betweenthe rotating reverse

disc and the transmission puiiey causes

thetransmission driveshaft to be

powered in a counterciockwise direction

(asviewedfrom the operator's position

behind handlebars)=The driveshaft then

turns the wheelsand tine shafts in a

reversedirection.

Figure 5-22: Measure the edge of

the reverse disc for wear.

2. Lookfor big cracks or missing chunks

of rubber from the disc. If so damaged,

the disc should be repiacedimmediately.

tI_IPORTANT: Extend theIife of the

reverse disc by always pausing in

NEUTRAL before shifting between

FORWARD and REVERSE. Also-the

reverse disc is not suited for continuous

or sustained reverse operation. Use

reversespanngiy.

35