Section5: Maintenance

iMPORTANT: Do not allow oiI or grease

to contact the pulleys, drive belt or

reverse disc. This can cause the belt or

disc to slip onthe putieys.

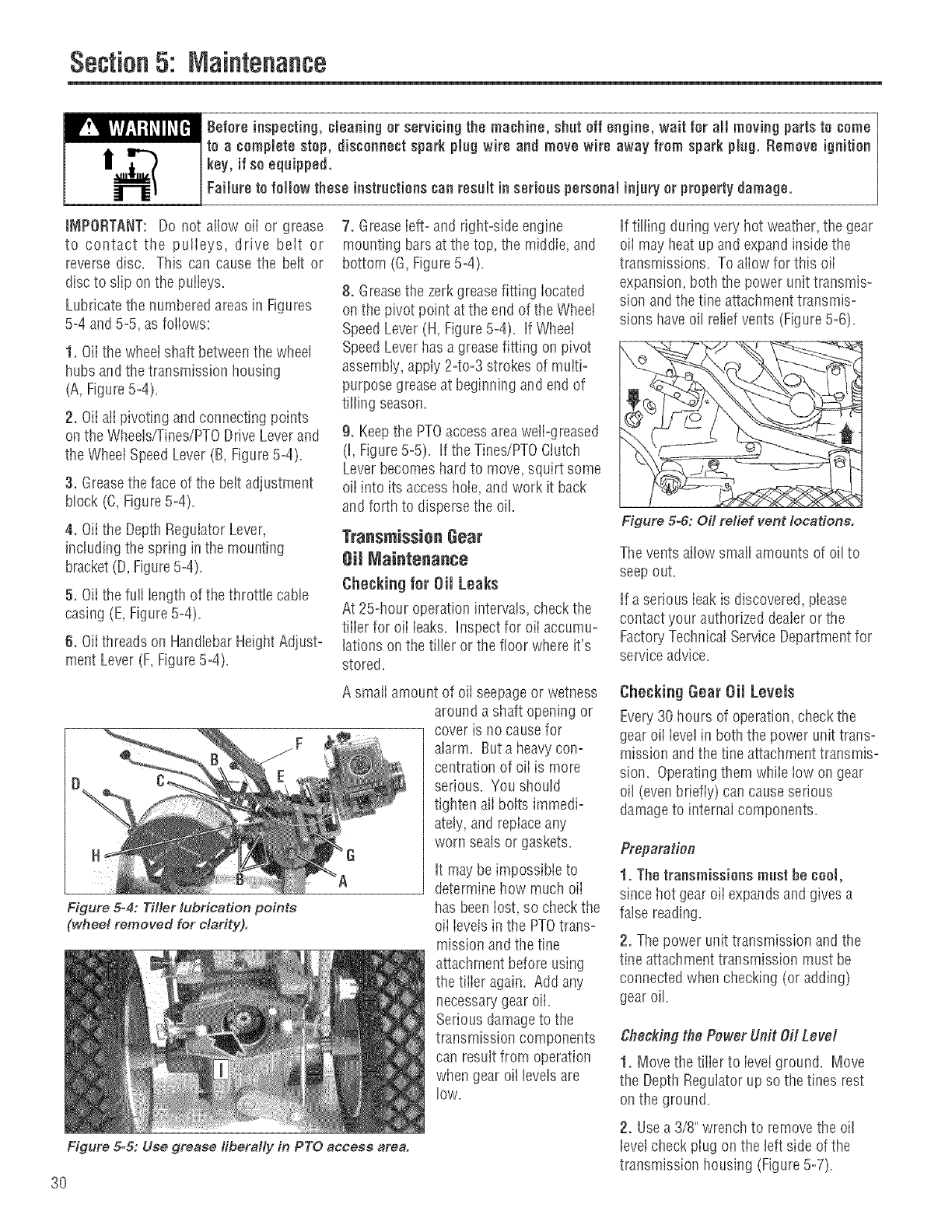

Lubricatethe numberedareasin Figures

5-4 and 5-5, asfoliows:

1. Oii the wheetshaft betweenthe wheel

hubsand the transmission housing

(A, Figure5-4).

2. Oii aii pivoting and connecting points

on ti_eWheels/Tines/PTODrive Leverand

the WheeiSpeed Lever(B, Figure5=4)=

3. Greasethe face ofthe beltadjustment

block (C, Figure5-4)=

4. OiIthe DepthRegulator Lever,

including the spring in the mounting

bracket(D, Figure5-4)=

5. Oii the furl iength of thethrottle cable

casing (E,Figure5-4).

6. Oii threads on HandlebarHeightAdjust-

ment Lever(F,Figure5-4)=

7. Greaseieft- and right-side engine

mounting barsat the top, the middie,and

bottom (6, Figure5-4)=

8. Greasethe zerkgreasefitting iocated

on the pivot point at the end of theWheei

SpeedLever(H, Figure5-4)= If Wheel

SpeedLeverhasa greasefitting on pivot

assembiy,appiy2-to-3 strokes of multi-

purposegreaseat beginning and end of

tilling season.

9. Keepthe PTOaccessareaweli-greased

(I, Figure5-5). if theTines/PTOCiutch

Leverbecomeshard to move,squirt some

off into its accesshole, and work it back

and forth to disperse the oil.

Transmission Gear

Oil Maintenance

Checkingfor Oil Leaks

At25-hour operationintervals, checkthe

tiiier for eli ieaks=Inspect for eli accumu-

btions on the tiller or the floor where it's

stored=

If tilling during very hot weather,the gear

oiI may heatup and expandinsidethe

transmissions. To aliow for this eli

expansion,both the power unit transmis-

sion and thetine attachment transmb-

sions haveoil relief vents (Figure5-6).

Figure 5-6: Oil relief vent locations.

Theventsallow smail amounts of oil to

seepout.

If a serious ieak is discovered,please

contact your authorized dealer or the

FactoryTechnicaiService Departmentfor

serviceadvice.

Figure 5=4: Tiller lubrication points

(wheel removed for clarity).

A smaii amount of eli seepageor wetness

around a shaft opening or

cover is no cause for

aiarm. Buta heavycon-

centration of eli is more

serious. You should

tighten ali botts immedi-

ately,and repiaceany

worn seais or gaskets.

G

It maybe impossibie to

determine how much eli

has beeniost, so checkthe

eli ieveis in the PTOtrans-

mission and the tine

attachmentbefore using

the tiiier again. Add any

necessarygear off.

Serious damageto the

transmission components

can resuit from operation

whengear oil levels are

low.

3O

Figure 5=5: Use grease fiberafly in PTO access area.

Checking Gear Oil Levels

Every30 hours of operation, @eck the

gear eli Ievelin boththe power unit trans-

mission and the tine attachmenttransmis-

sion. Operatingthem whiie iow on gear

oil (evenbriefly) cancause serious

damageto internai components.

Preparation

1. Thetransmissions must becoot,

since hot gear eli expandsand gives a

faise reading=

2. The power unit transmission andthe

tine attachmenttransmission must be

connectedwhenchecking (or adding)

gear oil.

Checkingthe Power Unit Off Level

t. Movethe tiiier to ieveiground. Move

the Depth Reguiator up sothe tines rest

on the ground.

2. Usea 3/8" wrench to removethe oil

levelcheck piug on the left side of the

transmission housing (Figure5-7)=