Section5: Maintenance

36

Before inspecting,deaning or servicing the machine, shut off engine, wait for all moving partsto came

to a cornpiete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition

key, if so equipped.

Failureto fellow these instructionscan result in serious personalinjury or propertydamage.

Replacing the Reverse Disc

Foilowthese stepsto repIacethe reverse

disc, (If your tiller hasa BumperAttach=

rnentmounted, it must be removedfirst=)

Removing the Reverse Disc

1. Move Wheets/rines/PTODrive Leverin

NEUTRALposition.

2. Wedgea 5/16"-thick board betweentop

of engine pulley (avoidcontacting reverse

disc) and cast iron housing next to it=

This immobilizes pulley=

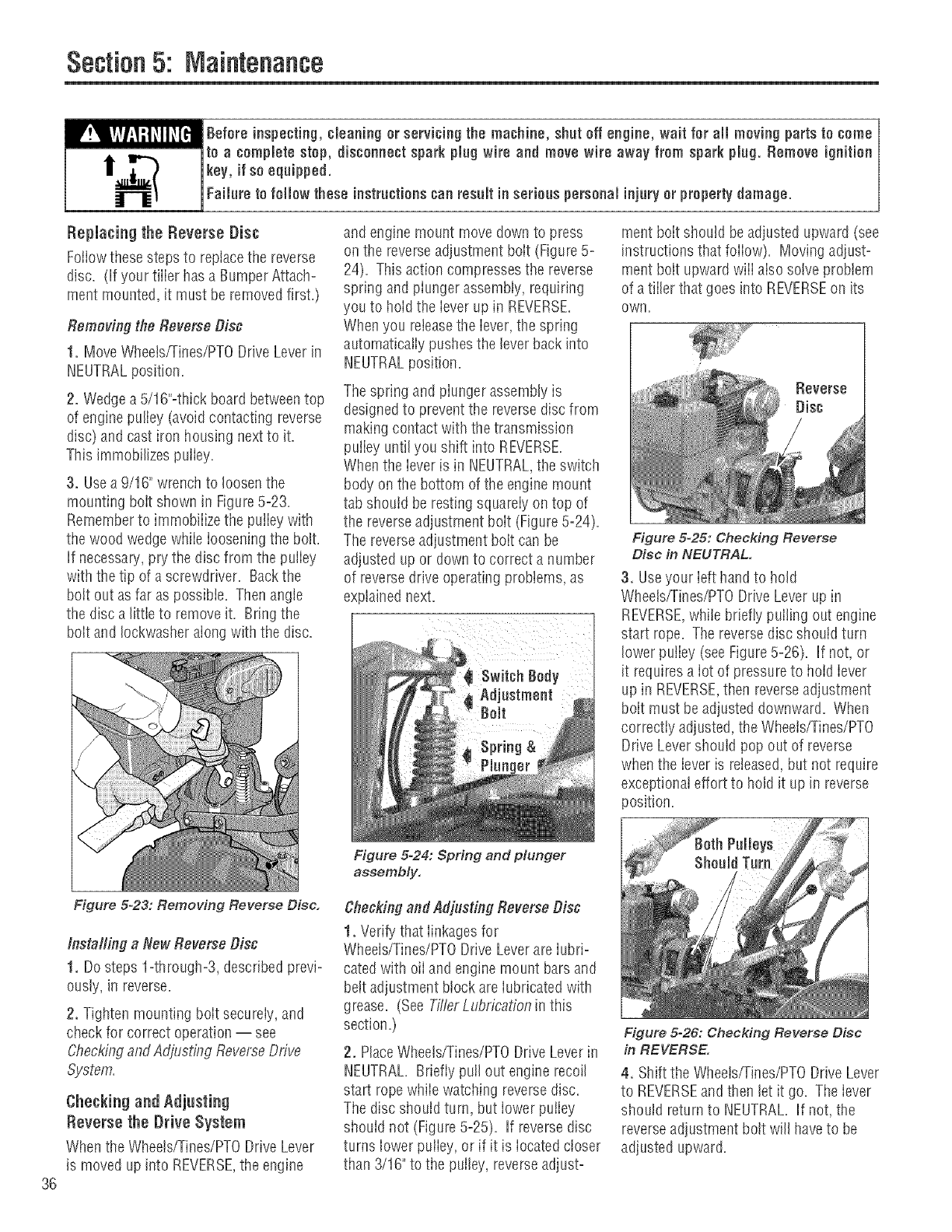

3. Usea 9/16" wrench to loosenthe

mounting bait shown in Figure5-23.

Rememberto irnrnobiiizethe pulieywith

the wood wedge whiie iooseningtire bolt.

If necessary,pry the disc from the puliey

with the tip of a screwdriver. Backthe

bait out asfar aspossible. Then angle

the disc a little to removeit. Bring the

bolt and Iockwasheralong with the disc.

Figure 5°23: Removing Reverse Disc.

/nstaltiflga New Reveme Disc

1. Dosteps 1=through-3,describedprevi-

ously, in reverse.

2. Tighten mounting bait securely, and

check for correct operation-- see

Checkingand Adjusting ReverseDrive

System=

Checking and Adjusting

Reverse the Drive System

Whenthe Wheels/Tines/PTODrive Lever

is moved up into REVERSE,the engine

and engine mount move downto press

on the reverseadjustment bolt (Figure5-

24). Tills action compressesthe reverse

spring and plunger assembly, requiring

you to hoid ti_eiever up in REVERSE.

Whenyou reieasethe iever,the spring

autornaticatiypushes the leverback into

NEUTRALposition.

Thespring and piunger assembly is

designedto preventthe reversedisc from

making contact with the transmission

puliey until you shift into REVERSE.

Whenthe ieveris in NEUTRAL,the switch

body on the bottom of the engine mount

tab shouid be resting squareiy on top of

the reverseadjustment bolt (Figure5-24)=

The reverseadjustment bait canbe

adjusted up ordownto correct a number

of reversedrive operating probierns, as

explainednext.

Figure 5°24: Spring and plunger

assembly.

Checking and Adjusting Reverse Dhc

1. Verify'that iinkages for

Wheels/Tines/PTODrive Leverare Iubri-

cated with oii and engine mount barsand

bettadjustment block are iubricated with

grease= (See TillerLubrication in this

section=)

2. PlaceWheels/Tines/PTODrive Leverin

NEUTRAL=Briefly pulIout engine recoil

start rope whiie watching reversedisc.

The disc should turn, but iower puiiey

should not (Figure5-25)= If reversedisc

turns lower puliey, or if it is iocated c!oser

than 3/16" to the putley, reverseadjust-

merit bait should be adjusted upward (see

instructions that follow). Moving adjust-

rnent bolt upward wiii alsosolve problem

of a tiiler thatgoes into REVERSEon its

OWn,

Figure 5-25: Checking Reverse

Disc in NEUTRAL.

3. Useyour ieft hand to hold

Wheels/Tines/PTODrive Leverup in

REVERSE,while briefly pulling out engine

start rope=The reversedisc shoutd turn

lower putiey (seeFigure5-26)= If not, or

it requiresa iot of pressureto hoid iever

up in REVERSE,then reverseadjustment

bait must be adjusted downward. When

correctly adjusted,the Wheeis/Tines/PTO

Drive Levershould pop out of reverse

whenthe ieveris reieased,but not require

exceptionaleffort to hold it up in reverse

position.

Figure 5°26: Checking Reverse Disc

in REVERSE.

4. Shift the Wheetsfrines/PTODrive Lever

to REVERSEand then let it go. The lever

should returnto NEUTRAL. If not, the

reverseadjustment bolt will haveto be

adjusted upward.