9. Assemble manifold (Item 22) and then the commuta-

tor ring (Item 23) over the drive link onto rotor set. Be

sure swirls in manifold and manifold plate are installed

facing together.

10. Assemble a new commutator seal (Item 15), flat side

up, into commutator (Item 16) and assemble commuta-

tor over end of drive link onto manifold with seal side up.

11. Install end cover (Item 24). Assemble special bolts

(Item 14) and screw in finger tight. Removal of the two

alignment studs should be made after at least two bolts

have been assembled. Alternately and progressively

tighten the bolts to pull end cover assembly into place

with final torque of 50 ± 5 ft.lbs. (68 ± 8 Nm).

12. Invert housing in vise so the coupling shaft (Item 11)

is pointing up and install dust seal (Item 1). Seal should

be pressing in flush to 0.02 inch below face.

NOTE: Torque required to rotate coupling shaft should

not be more than 50 ft-lb (68 Nm).

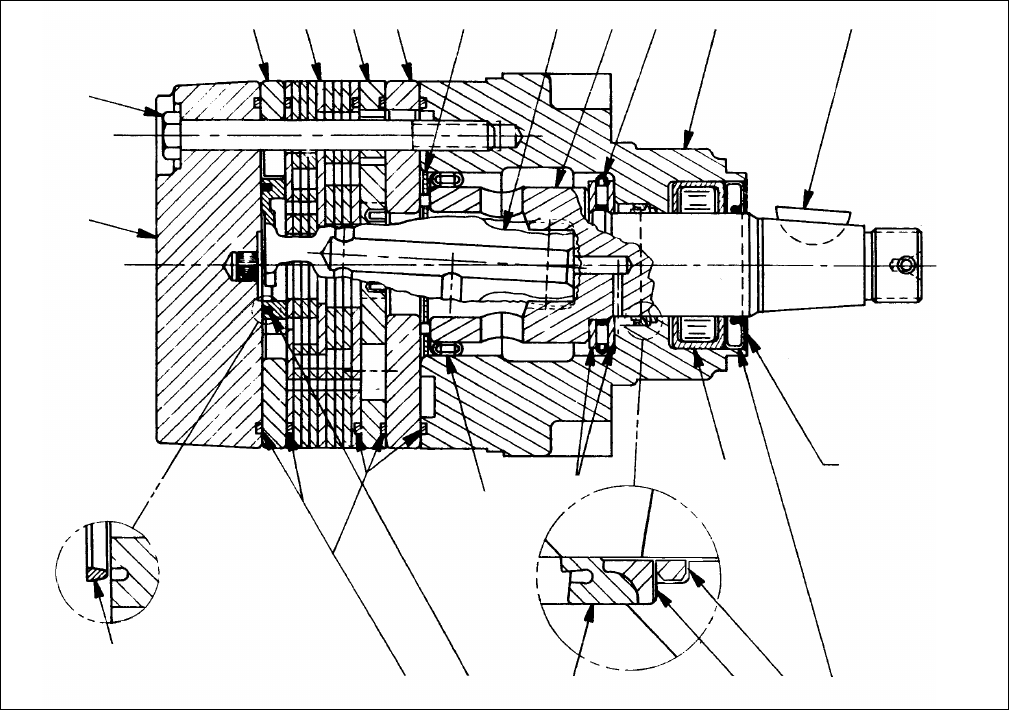

Rotor, Stator and Vane Assembly (Fig. 37, 38)

1. Place stator (Item 21) onto wear plate (Item 18) after

doing motor assembly procedures 1 through 7.

2. If assembly alignment studs are not being used, align

stator bolt holes with wear plate bolt holes and turn two

(2) bolts (Item 14) finger tight into bolt holes 180° apart

to keep stator and wear plate stationary.

3. Assemble six vanes (Item 20) into the stator vane

pockets.

4. Assemble rotor (Item 19), counterbore down, if appli-

cable, into stator (Item 21) and onto wear plate (Item 18)

with rotor splines in mesh with drive link splines.

5. Grasp output end of coupling shaft (Item 11) and

rotate coupling shaft, drive link and rotor to seat the rotor

and assembled vanes into stator, creating necessary

clearance to assemble seventh (7th) vane. Assemble

the seven (7) vanes using minimum force.

6. Remove the two assembled bolts if used to retain

stator and wear plate.

Figure 38

1

2

3

4

5

22

23

24

6

7

8

9

10

19,20,21

11

12

13

14

15

16

17

18

Press seal in flush

to 0.020 inch below

face

Greensmaster

®

3100 Page 4 - 57 Repairs