Greensmaster 3100

Dual Point Adjust Cutting units

Page 10 - 13

Bedknife Replacement and Grinding

Removal

1. Remove bedbar from frame (see Bedbar Removal).

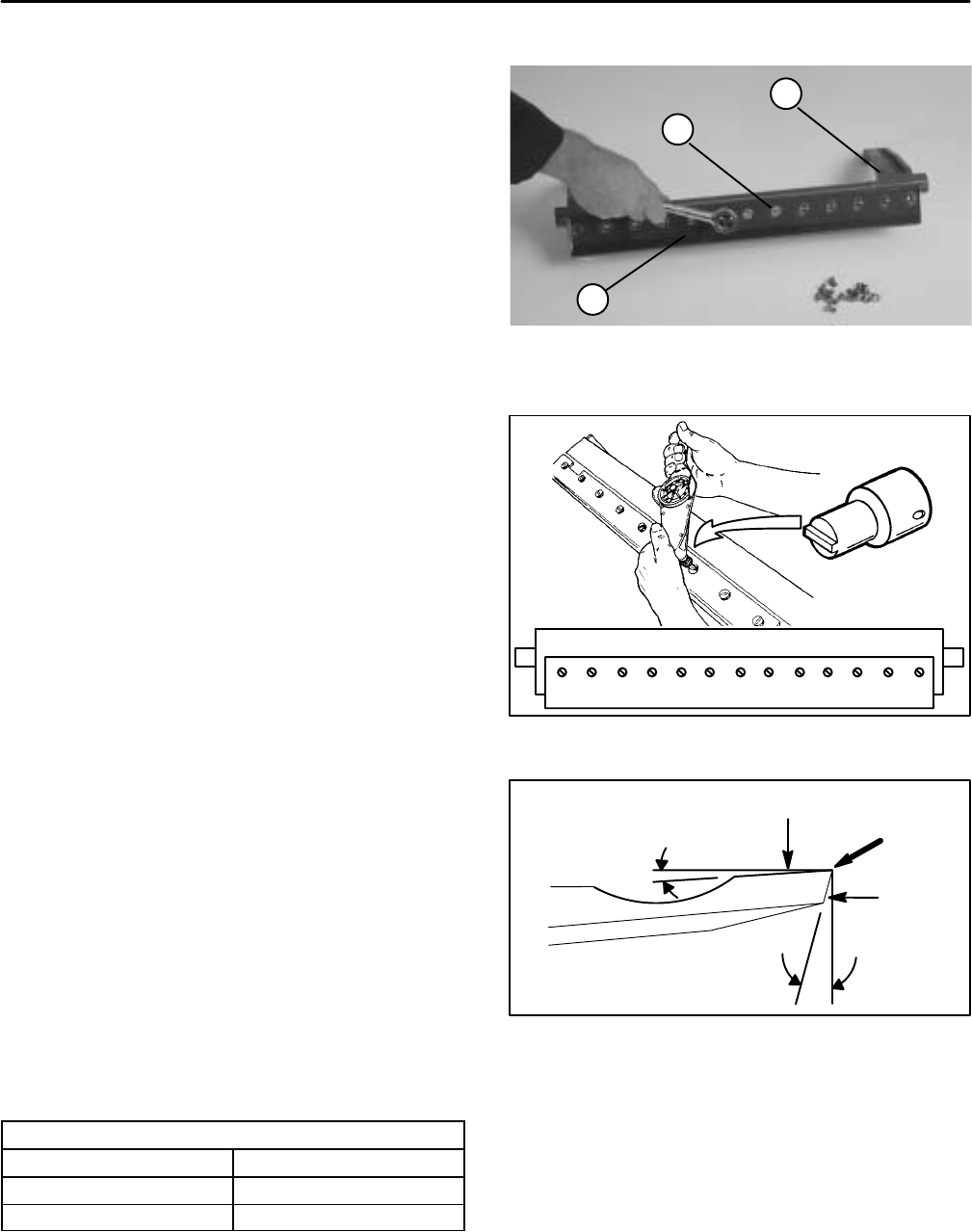

2. Remove screws from bedbar using a socket wrench

and bedknife screw tool (see Special Tools). Discard

screws. Remove bedknife from the bedbar (Fig. 13).

3. Use scraper to remove all rust, scale and corrosion

from bedbar surface before installing bedknife.

Replacement

1. Make sure bedbar threads are clean. Use new

screws. Apply clean SAE 30 oil to the screws before

installing.

IMPORTANT: Do not use an impact wrench to tight-

en screws into the bedbar.

2. Using a torque wrench and bedknife screw tool,

tighten screws to a torque of 200 to 250 in–lb (22 to

28 Nm). Use a torquing pattern working from the center

toward each end of the bedknife (Fig. 14).

3. Install bedbar to frame (see Bedbar Installation).

Grinding

Since there can be variations in the mounting surface of

the bedbar, a new bedknife will not be perfectly flat after

it is installed. Because of this, it is necessary to backlap

or grind a new bedknife after installing it to the bedbar.

Follow the existing angle that was ground into the bed-

knife and grind only enough to make sure the top surface

is true (Fig. 15).

1. Remove bedbar from the cutting unit (see Bedbar

Removal).

Note: When grinding, be careful to not overheat the

bedknife. Remove small amounts of material with each

pass of the grinder.

2. Use Toro Service Training Book, Sharpening Reel

and Rotary Mowers (part no. 80300SL) for bedknife

grinding information.

Bedknife Grinding Specifications

Bedknife relief angle

3_ (see Fig. 15)

Front Angle

13_

Front Angle Range

13_ to 17_

3. Reinstall bedbar to cutting unit (see Bedbar Installa-

tion).

1. Screw

2. Bedbar

3. Bedknife

Figure 13

1

2

3

12 46 83579 10 12

1113

Figure 14

Figure 15

Relief Angle

Front Angle

Top Face

Front

Face

Remove

Burr

NOTE: Relief angle is 7

o

for special "extended" bedknives

Rev. D