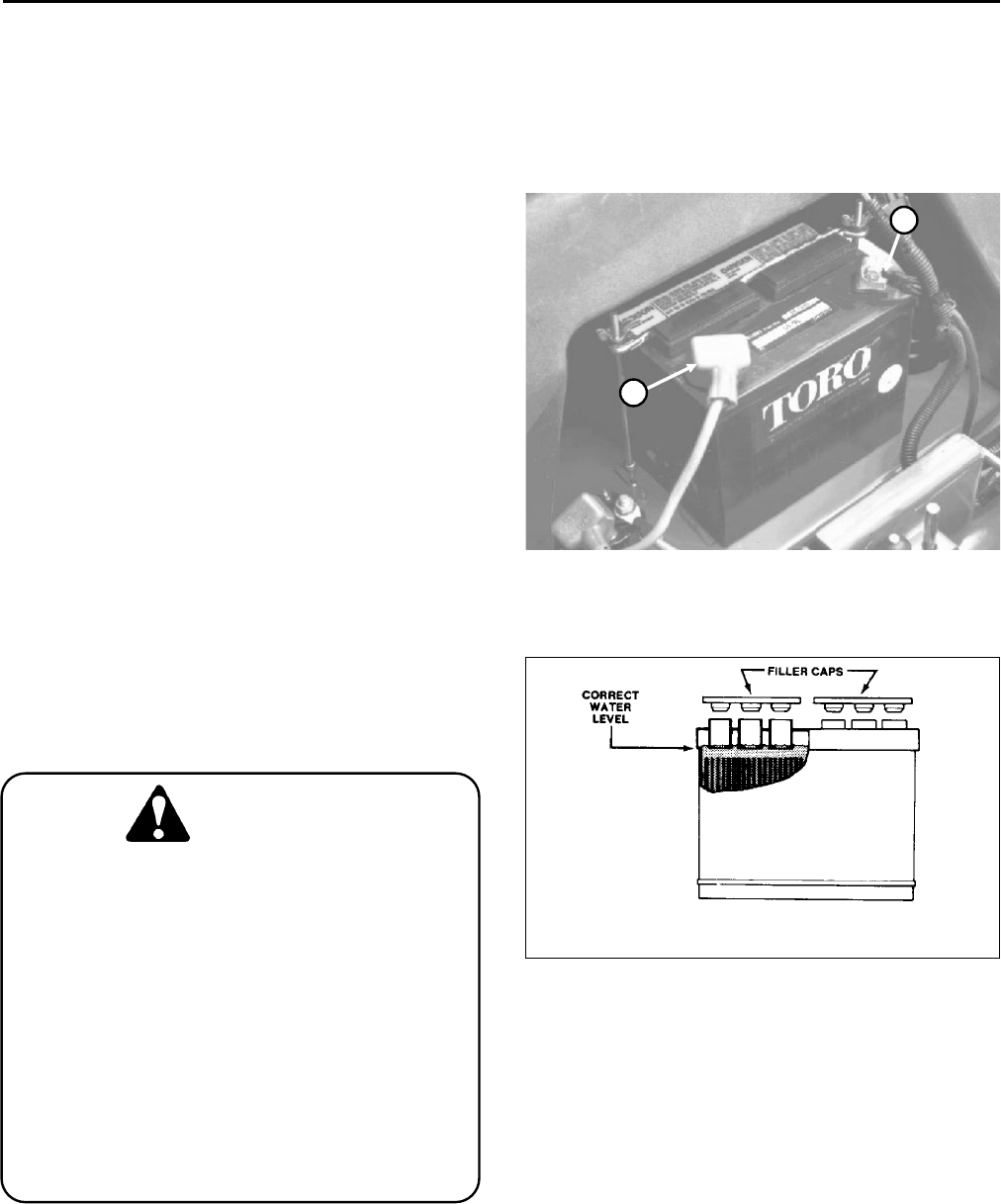

Battery Service (Fig. 18, 19)

IMPORTANT: Before welding on the machine, dis-

connect the negative (–) battery cable from the bat-

tery to prevent damage to the electrical system.

IMPORTANT: To prevent damage to the electrical

components, do not operate the engine with the

battery cables disconnected.

Keep the terminals and entire battery case clean. To

clean the battery, wash the entire case with a solution

of baking soda and water. Rinse with clear water. Do not

get the soda solution into the battery because damage

to the battery will result. Coat the battery posts and cable

connectors with skin-over grease, or petroleum jelly to

prevent corrosion.

Check for loose battery hold-downs. A loose battery may

crack or cause the container to wear and leak acid.

Check the electrolyte solution to make sure the level is

above the plates. If the level is low (but above the plates

inside the battery), add water so the level is to the

bottom of the cap tubes. If the level is below the plates,

add water only until the plates are covered and then

charge the battery. After charging, fill the battery to the

proper level.

Electrolyte Specific Gravity

Fully charged: 1.250 - 1.280

Discharged: less than 1.240

Do not charge a frozen battery because it can

explode and cause injury. Let the battery

warm to 60

o

F (15.5

o

C) before connecting to

a charger.

Charge the battery in a well-ventilated place

so that gases produced while charging can

dissipate. Since the gases are explosive, keep

open flame and electrical spark away from the

battery; do not smoke. Nausea may result if

the gases are inhaled. Unplug the charger

from the electrical outlet before connecting or

disconnecting the charger leads from the bat-

tery posts.

Battery Specifications

BCI Group U1 Battery

200 Amp Cranking Performance at 0

o

F (17

o

C)

32 min. Reserve Capacity at 80

o

F (27

o

C)

Figure 18

1. Positive (+) terminal

2. Negative (–) terminal

Figure 19

WARNING

2

1

Repairs Page 5 - 16 Greensmaster

®

3100