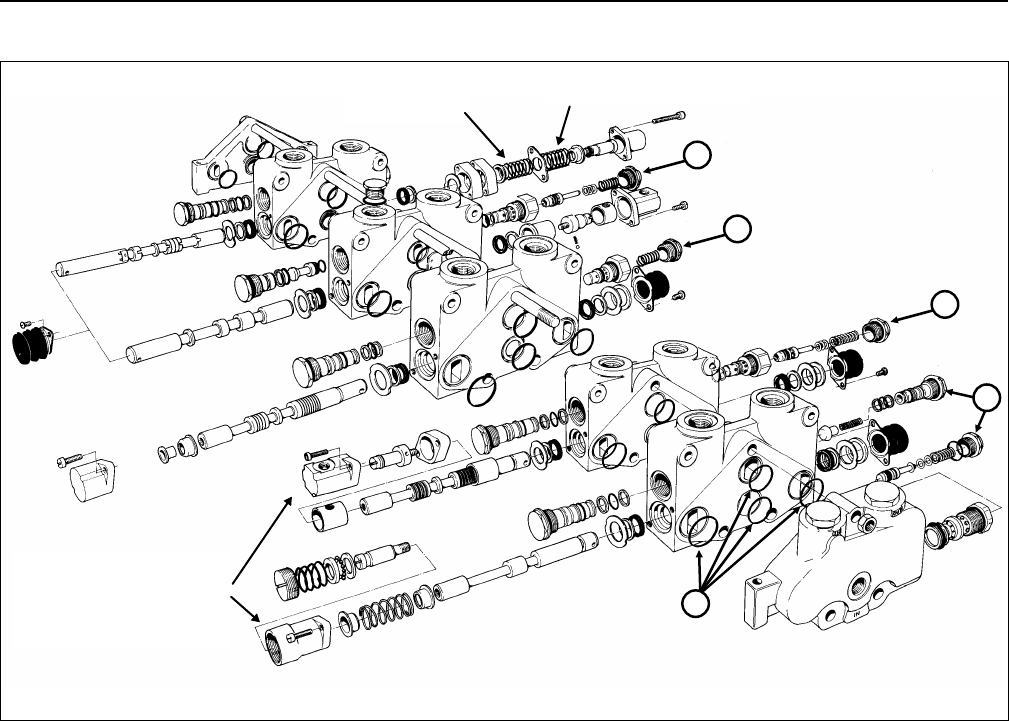

Control Valve Internal Seal Replacement (Fig. 27)

Figure 27

1. Internal seals (4 between ea. sect.) 3. No. 2 section relief valve 5. No. 4 (traction) section relief valve

2. Main & No. 1 section relief valve 4. No. 3 section relief valve

NOTE: Replace all internal seals whenever valve sec-

tions are disassembled. Original seals may not seal

after the valve assembly is installed on the machine.

1. Remove the valve bank. (See Control Valve Removal

and Installation in this section of the book.)

2. Put the valve bank in a vertical position in a bench

vise, and remove the locknuts from the three (3) bolts

securing the sections together (Fig. 27).

3. Slide each section off the studs. Identify them so they

will not be reassembled in the wrong location.

4. Remove all original o-ring seals, clean the o-ring

grooves and check the mating surfaces of each section

for any imperfections or contaminants which could

cause leakage to occur.

5. Soak the replacement o-rings in clean hydraulic fluid

and install them into the ring grooves as you stack each

section on top of another.

6. Install the locknuts onto the studs and torque them to

15-20 ft-lb (20.4-27.2 Nm).

IMPORTANT: Do not overtorque. This will distort the

valve bodies and cause binding of the spools.

7. Install the valve bank onto the machine.

4

2

1

5

3

Greensmaster

®

3100 Page 4 - 47 Repairs

These components

changed locations after

serial no. 210000701

1.5 in. spring

2.5 in. traction spring