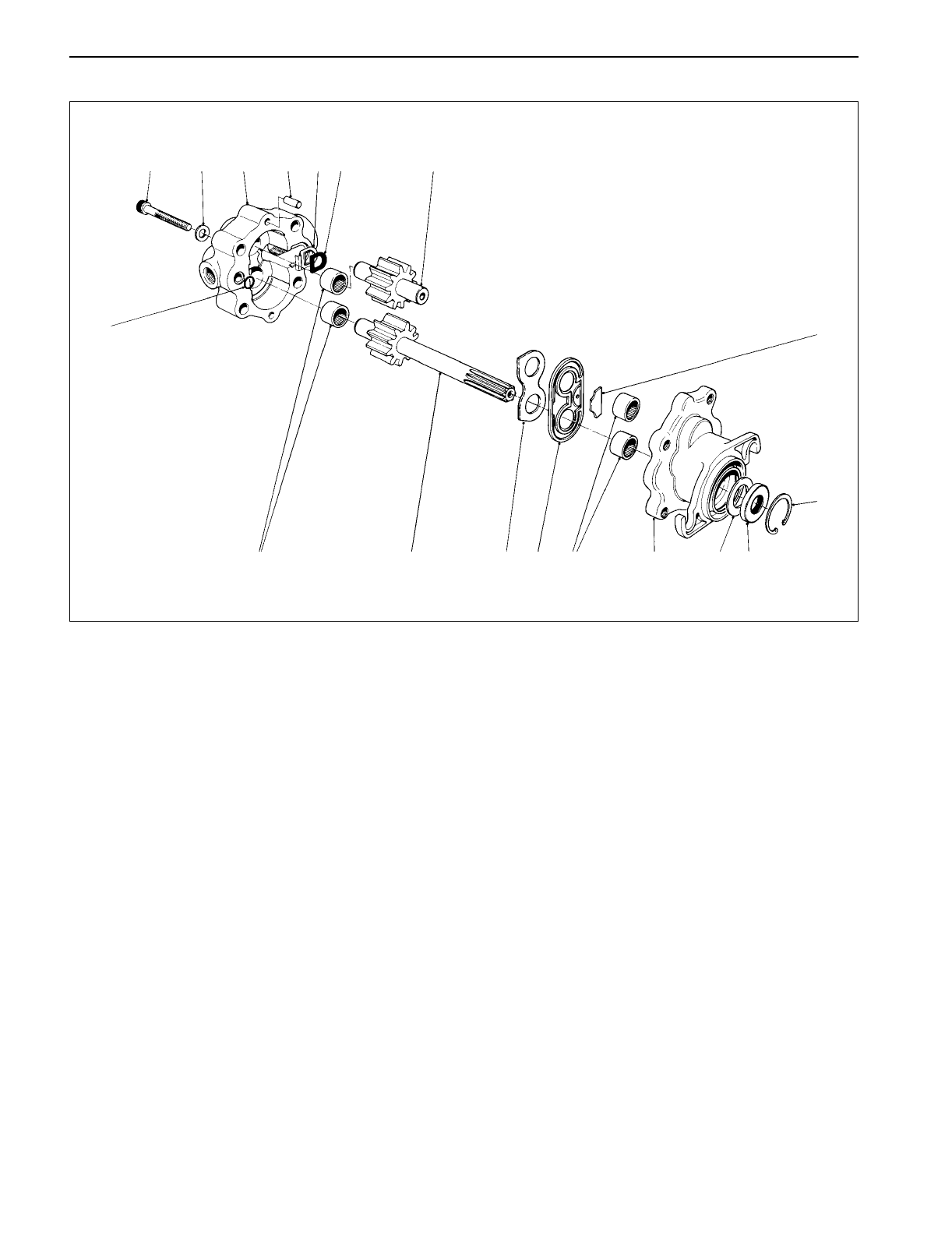

Reel Motor 70-9800 Repair (Fig. 18)

Figure 18

1. Plug ports and wash exterior of motor with mineral

spirits or solvent. Make sure parts and work area are

clean.

IMPORTANT: Extreme caution must be used when

using a vise to avoid distorting any parts.

2. Draw a line across the seam areas on the motor case

with a scribe or marker to ensure proper reassembly.

3. Remove four socket head capscrews.

4. Put your hand on the cover assembly and gently tap

the drive shaft with a soft face hammer to separate the

body from the cover. Be careful not to drop parts or

disengage gear mesh.

5. Before removing gear set, apply marking dye to

mating teeth to retain “timing” when reassembling.

6. Be careful when disassembling. The needle bearings

may be of the loose grease retained type. Pack these

with general purpose grease to retain them for reassem-

bly. It is recommended NOT to remove the bearing races

from the cover and body.

7. Remove and discard the bridging insert, gasket in-

sert, anti-extrusion block, snap ring, shaft seal, spacer,

seal assembly, wear plate and o-ring, (Items 5, 6, 8-11,

14, 15 and 17). These items are available in a repair kit.

8. Clean all parts and check for burrs, scoring,

nicks, etc.

9. Rub mating surfaces of body and cover with 400 grit

or finer sandpaper to remove any Loctite residue. Wash

body and cover to remove abrasive material.

10. Apply grease to bridging insert and put in cover, tab

side down.

11. Apply grease to gasket insert and put in place over

bridging insert.

12. Stone gears if wear plate appears scored. Replace

as set if necessary. Oil the inside of cover and insert the

gear set, maintaining the original timing and locations.

13. Apply grease to wear plate and slip over shafts with

wider cross section next to bridging insert. If the wear

plate is made of steel backed bronze, the bronze side

must face gears.

Rev. B

1

2

3

4

5

6

7

8

9

17

13 16

11

13

1415

10

12

Repairs Page 4 - 40

Greensmaster

®

3100