Greensmaster 3100 Page 4–41.4 RepairsRev. D

IMPORTANT: Avoid using excessive clamping

pressure on the motor flange to prevent distorting

the casting.

3. Clamp mounting flange of motor in a vise with the

shaft end down.

4. Loosen cap screws on the rear cover.

5. Take motor from the vise and remove cap screws.

6. Remove front flange from the body, then remove rear

cover. Locate and remove dowel pins from body.

IMPORTANT: Mark the relative positions of the gear

teeth and the bearing blocks so they can be re-

assembled in the same position. Do not touch the

gear surfaces as residue on hands may be corrosive

to gear finish.

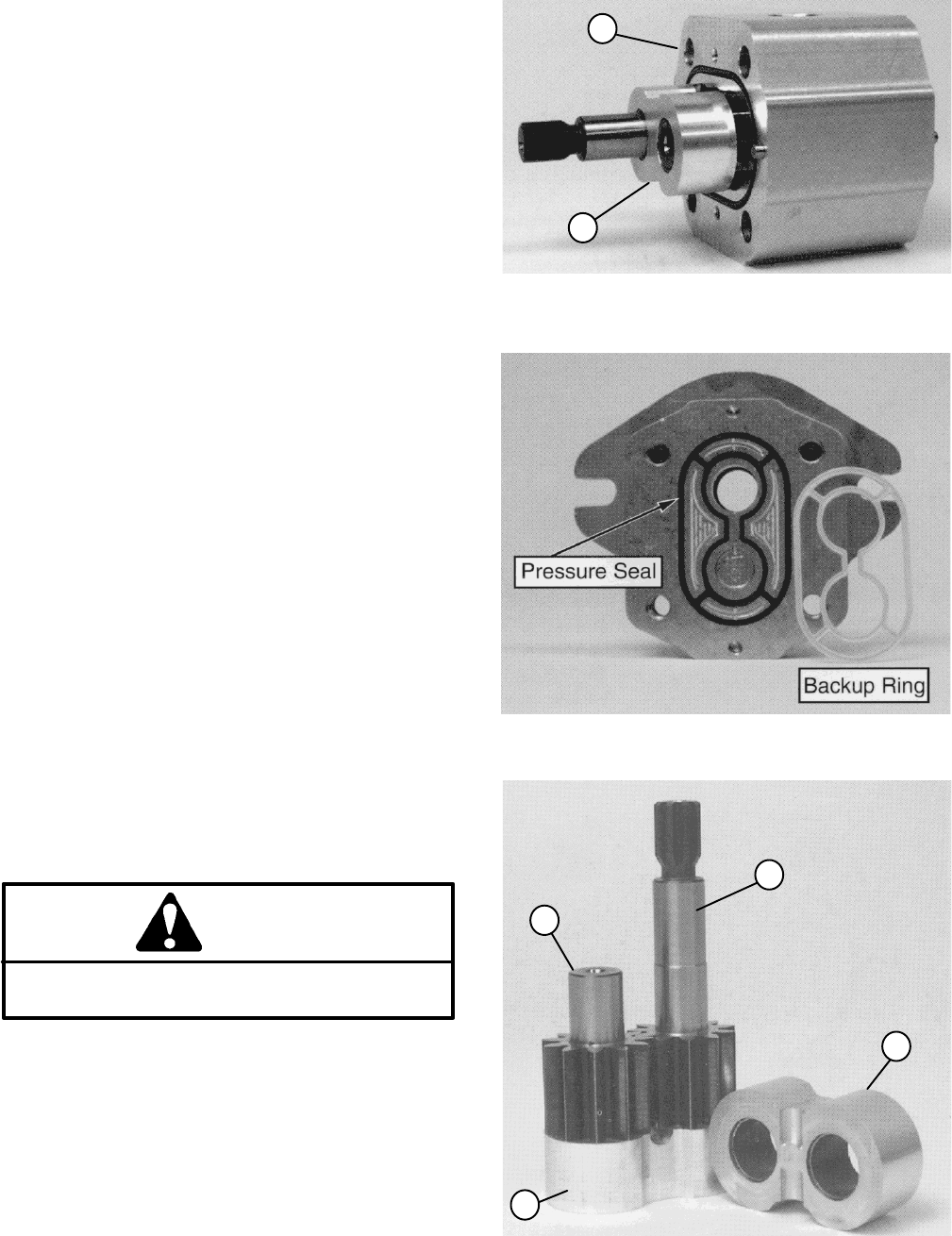

7. Place the motor on its side and push on the rear bear-

ing block to remove the bearing block and gear set (Fig.

18d).

8. Carefully remove and discard o–rings, pressure

seals, and back–up rings (Fig. 18e) from motor. Do not

cause any damage to the machined grooves during the

removal process.

IMPORTANT: Make sure not to damage the counter

bore when removing the shaft seal from the front

plate.

9. Position front flange with seal side up. Remove shaft

seal.

Inspection

1. Remove any nicks and burrs from all motor compo-

nents with emery cloth.

CAUTION

Use eye protection such as goggles when using

compressed air.

2. Clean all motor components with solvent. Dry all

parts with compressed air.

1. Motor body 2. Bearing block & gear set

Figure 18d

2

1

Figure 18e

1. Drive gear

2. Idler gear

3. Bearing block

Figure 18f

1

3

3

2