Greensmaster 3100

Dual Point Adjust Cutting units

Page 10 - 17

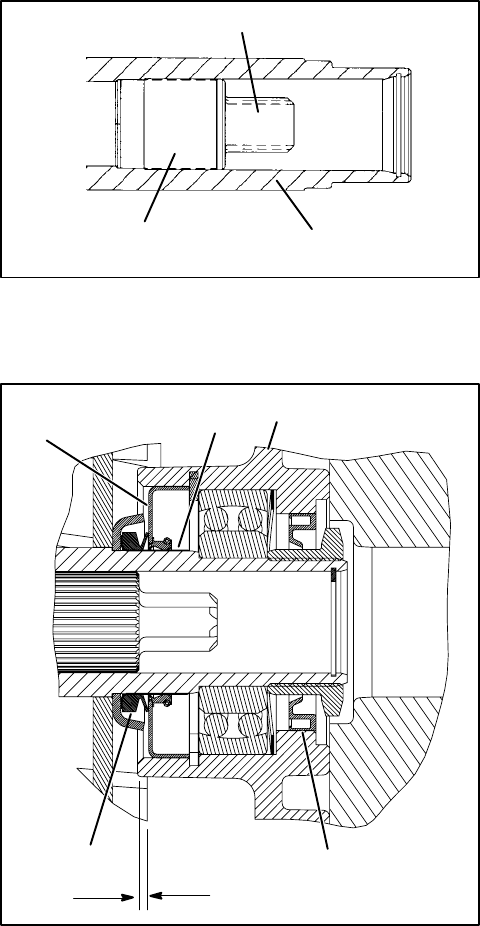

Reel Service (Fig. 16)

Note: Install new reel components on each end of the

reel shaft that mates with newly serviced side plate com-

ponents.

1. Remove the retaining ring (5) and the drive coupler

(4) from the end of the reel shaft.

2. Remove the V–ring (3) from the reel shaft.

3. Using a flat blade screw driver or similar tool, re-

move the speedi sleeve (2) from the reel shaft.

Note: Replacemant Seal Kit (Toro Part No. 106-6937)

is available for reel service of dual point adjust cutting

units.

4. Inspect the reel shaft as follows:

A. Check the reel shaft for bending and distortion

by placing the shaft ends in V–blocks. Replace the

reel if necessary.

B. Check the reel blades for bending or cracking

Replace the reel if necessary.

C. Check the drive adapter inside of the reel shaft

(Fig. 19). The adapter should be free of bending and

distortion. Check the splines for excessive cracks or

distortion. Replace the reel if necessary.

D. Check the service limit of the reel diameter. Re-

place the reel if necessary.

5. Using an appropriate I.D. tube or sleeve, press the

speedi sleeve onto the reel shaft until it bottoms out on

the spider cup (Fig. 20).

IMPORTANT: Do not nick or scratch the Speedi

sleeve surface as seal failure could result.

6. Slide the V–ring onto the reel shaft with the thick

shoulder of the V–ring facing inward (Fig. 20).

7. Fill the drive coupling (4) 1/2 to 1/3 full with Mobil

High Temperature HP or equivalent grease. Also, coat

the outside of the drive coupling with grease.

8. Install the retaining ring (5). Make sure it is seated

into the groove.

1. Reel shaft

2. Drive adapter

3. Adapter spline

Figure 19

12

3

1. Outer seal

2. Inner seal

3. Speedi sleeve

4. V-ring

5. Left side plate

Figure 20

1

.104 Seal Depth

4

2

3

5

Rev. D