Repairs

General Safety Interlock Switch Service

The following procedures should be followed whenever

a switch requires adjustment or replacement:

1. Be sure rubber boot is reinstalled in both switch

grooves on the button end of seat switch after it is

properly adjusted.

IMPORTANT: Rubber boot on button end must be in

place to make sure all dirt, moisture and grease are

kept from the plunger sides.

2. Spread Skin-Over grease heavily over the terminal

end and inside the terminal cover of all switches before

installing the connectors and terminal cover. Be sure the

wires are fully connected.

3. Make sure terminal cover is fully installed over end of

switch.

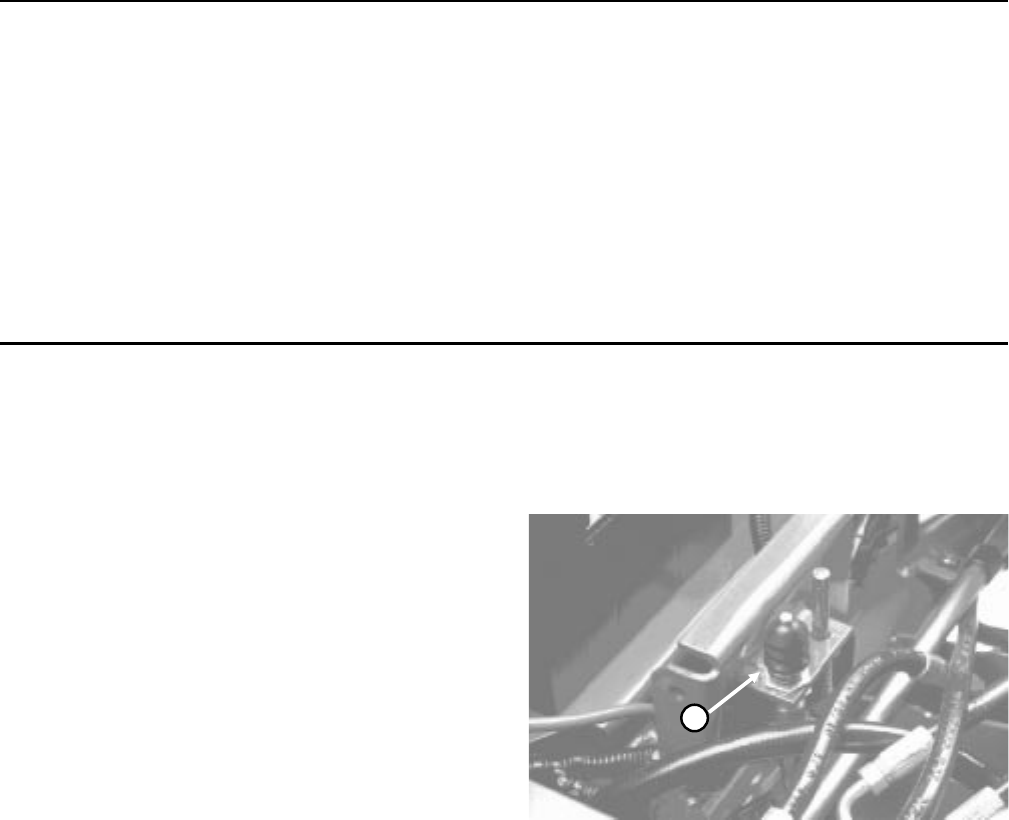

Seat Switch Replacement and Adjustment (Fig. 15)

1. Pivot seat forward and block or tie it securely to

prevent it from falling accidentally and possibly causing

injury.

2. Remove boot from button end of seat switch and

retain for installation on replacement switch. Pull con-

nectors off switch terminals.

3. Loosen the jam nut and unscrew the switch from

mounting bracket.

4. Screw new switch through mounting bracket until

switch button is about 1/16 inch (1.6 mm) shorter than

the top of the seat return spring pin. Install the boot into

the mount grooves.

5. Carefully release the seat to its normally down posi-

tion, but do not sit or apply force on the seat. There

should be a slight gap between the switch and the seat

plate.

6. Make sure switch terminals face front of machine and

lock switch in place by tightening the jam nut to 75 in.-lb

(8.5 Nm) against the mounting bracket.

IMPORTANT: Switch threads will be damaged if the

jam nut is over-tightened.

7. Connect continuity tester of ohm meter to switch

terminals. With seat in the down position and no one on

the seat, the switch circuit should not have continuity. If

there is continuity, repeat steps 4-6. If there is no conti-

nuity, proceed to

8. Sit on the seat. The seat switch should have continu-

ity. If there is no continuity, repeat steps 4-7. If there is

continuity proceed to step 9.

9. Fill terminal end of switch and wiring harness cover

with skin-over grease and push connectors onto switch

terminals. Be sure connectors are fully connected and

slide cover over bottom of switch body.

Figure 15

1. Seat switch

1

Greensmaster

®

3100 Page 5 - 13 Repairs