SECTION 2.4

DIAGNOSTIC TESTS

AC GENERATORS

RESULTS:

1. If the resistance reading is correct, check your VOM

meters fuse and repeat Test 4.

2. If INFINITY is measured on your VOM meter, go to Test 9.

TEST

9

-

CHECK

BRUSHES

AND

SLIP

RINGS

DISCUSSION:

The function of the brushes and slip rings is to provide for

passage of excitation current from stationary components to the

rotating rotor. Brushes are made of a special long lasting

material and seldom wear out or fail. However, slip rings can

develop a tarnish or film that can inhibit or offer a resistance to

the flow of electricity. Such a non-conducting film usually

develops during non-operating periods. Broken or disconnected

wiring can also cause loss of excitation current to the rotor.

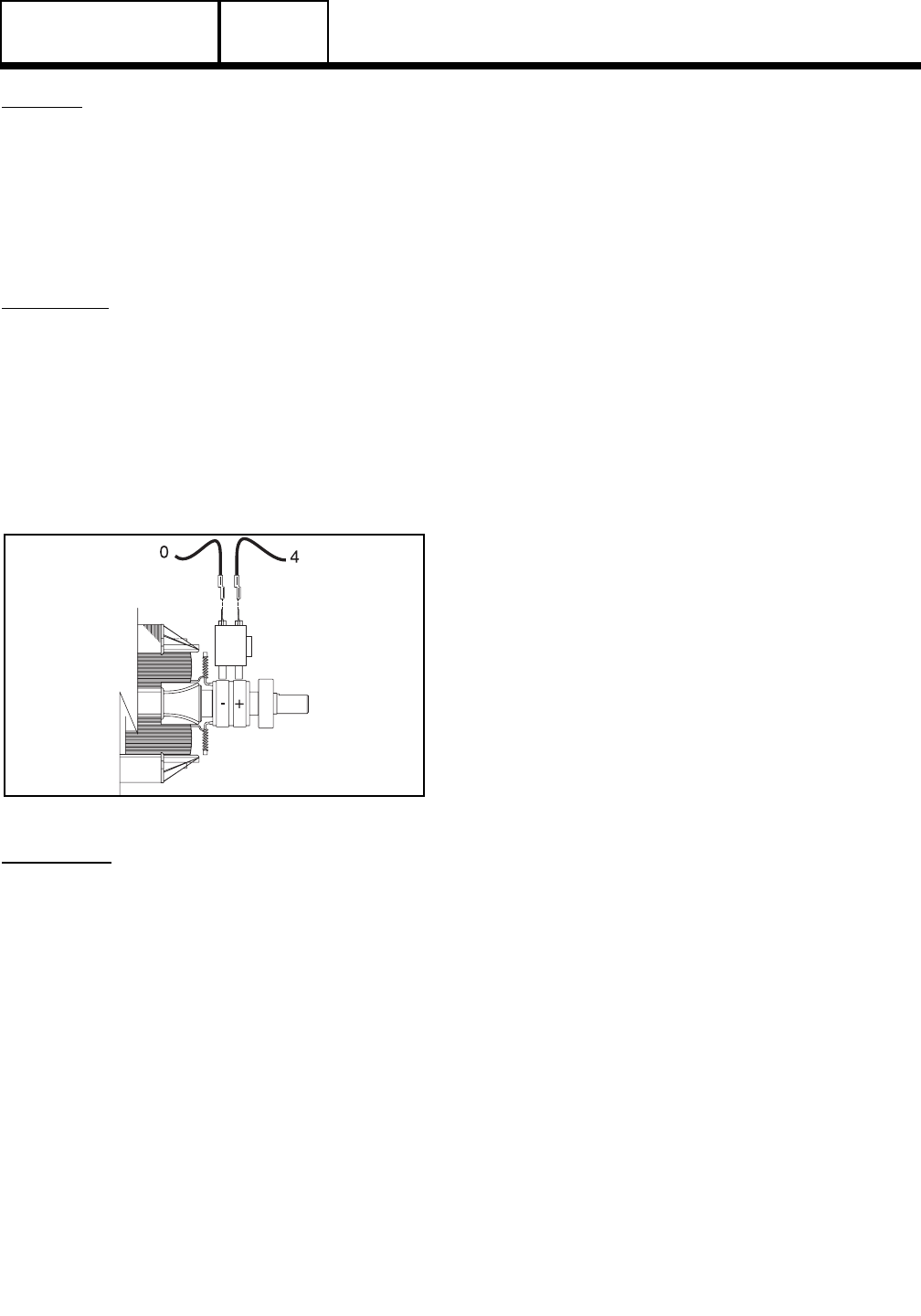

Figure 7. Checking Brushes and Slip Rings

PROCEDURE:

1. Disconnect connector C2 (deutsch connector closest to

the back panel). Refer to figure 5 and figure 6 on page

2.4-5.

2. Set a VOM to measure resistance.

3. Connect one meter test lead to Pin 9 (Wire 0) of the C2

connector (female side). Connect the other meter test

lead to Pin 10 (Wire 4) of the C2 connector (female

side). Rotor resistance should be measured see

specifications on page 2. If rotor resistance is not

measured proceed to step 4. If rotor resistance is

measured proceed to step 12.

4. See figure 7. Carefully inspect brush wires; make sure

they are properly and securely connected.

5. Wire 0 from the negative (-) brush terminal connects to

Pin 9 of the C2 connector.

Test this wire for an open condition. Remove wire 0

from the brush assembly. Connect one meter test lead

to wire 0. Connect the other test lead to Pin 9 (wire 0)

of the C2 connector ( female side). CONTINUITY

should be measured. If INFINITY is measured repair or

replace wire 0 between the brush assembly and the C2

connector.

6. Wire 4 from the positive (+) brush terminal connects to

Pin 10 of the C2 connector.Test this wire for an open

condition. Remove wire 4 from the brush assembly.

Connect one meter test lead to Wire 4. Connect the

other meter test lead to Pin 10 (wire 0) of the C2

connector (female side). CONTINUITY should be

measured. If INFINITY is measured repair or replace

wire 4 between the brush assembly and the C2

connector.

7. Connect one meter test lead to wire 4 Connect the

other meter test lead to frame ground. INFINITY should

be measured. If CONTINUITY is measured a short to

ground exists on wire 4 repair or replace wire 4

between the brush assembly and the C2 connector.

8. If continuity was measured in steps 5 and 6 proceed to

step 9.

9. Disconnect wires 0 and 4 from the brush assembly.

Remove the brush assembly from the bearing carrier.

Inspect the brushes for excessive wear,damage.

10. Inspect the rotor slip rings. If they appear dull or

tarnished, they may be polished with a fine sandpaper.

DO NOT USE METALLIC GRIT TO POLISH SLIP

RINGS.

11. If brush assembly and slip rings look good proceed to

Test 10 ( Test Rotor assembly)

12. Wire 0 connects from the C2 connector to the control

panel ground lug. Connect one meter test lead to Pin 9

(Wire 0) of the C2 connector (male side). Connect the

other meter test lead to the ground terminal in the

control panel. CONTINUITY should be measured. If

INFINITY is measured repair or replace wire 0 between

the C2 connector and the ground terminal.

13. Remove wire 4 from the voltage regulator.

PART 2

Page 2.4-7