12.0 Troubleshooting

NOTICE: Use of the material contained in this document is subject to the warning on page Iv and the disclaimer

on page v of this document.

DOC012R02 AOC 15/50 User Manual Nov 2001

97

The rotor is brought to a complete stop by the parking brake, which is engaged after a delay of

several seconds. Should the dynamic brake fail, the rotor can over-speed during the time delay

period, in which case, the tip brakes may deploy centrifugally to prevent over-speed.

Should any of the tip brakes deploy, other than for normal shutdowns and for reasons not related

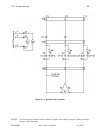

to a fault in their electrical circuits, the dynamic and parking brakes should be checked. A fault

in the dynamic brake could be due to any of its electrical components. The resistors, capacitors

and contactors should, therefore, be checked to if a problem with the dynamic brake occurs.

The parking brake is located on the upwind end of the generator. It is an electrically operated

dry-disc brake, engaged to the high-speed shaft via a splined coupling. When energized, a

solenoid releases the spring pressure on the disc, allowing the drive train to rotate freely. De-

energizing the solenoid brings the stationary and friction discs back in to contact again, causing

the rotor to stop and be held by a torque of 314 Nm (230 ft-lbs).

If the parking brake does not release, its solenoid may be faulty. This can be verified by

manually releasing the brake by pulling on its brake release handle. Furthermore, the friction

discs can become stuck in the brake housing, preventing the brake from releasing. The

condition of the solenoid can be checked with an ohmmeter. The correct resistance across the

leads is approximately 1.5 ohms.

If the parking brake does not engage, the pressure spring could be defective or the friction disc

could be stuck or damaged.