Groundsmaster 4010--D Operator CabPage 9 -- 5

7. Read the General Precautions for Removing and

Installing Air Conditioning System Components at the

beginning of the Service and Repairs section of this

chapter.

CAUTION

The air conditioning system is under high pres-

sure. Do not loosen any system fitting or compo-

nent until after the system has been completely

discharged by a certified A/C service technician.

8. Have refrigerant evacuated from air conditioning

system by a certified A/C service technician.

9. Label and remove hoses from compressor. Immedi-

atelycap hoses and fittingsto preventmoisture andcon-

taminants from entering the system.

10.Support compressor to prevent it from shifting or fal-

ling.

NOTE: There may be shims mounted between com-

pressor and compressor mount. When removing com-

pressor, note shim location and quantity for assembly

purposes.

11.Remove fasteners and washers that secure com-

pressor to compressor mount.

IMPORTANT: To prevent compressor oil from filling

the compressor cylinders, keep compressor in the

same orientation as the installed position.

12.Carefully remove compressor from engine and ma-

chine.

NOTE: Thereplacementof thedrier--receiver isrecom-

mendedwhenever A/Ccompressoris removedfrom the

system (see Heater and Evaporator Assembly in this

section).

NOTE: The air conditioning compressor used on the

Groundsmaster 4 010--D is a Sanden model SD5H09.

For air conditioning compressor repair procedures, see

the Sanden SD Compressor Service Guide at the end

of this chapter.

Installation (Fig. 1)

1. Position compressor to compressor mount on en-

gine.

NOTE: Theclearance between thecompressor mount-

ing flanges and compressor mount must be less than

0.004” (0.10 mm). If necessary, install shims between

compressor flanges andmount toadjust clearance. See

Compressor Parts Catalog for shim kit.

2. Secure compressor to compressor mount with re-

moved fasteners and spacers. Do not fully tighten fas-

teners.

IMPORTANT: After the compressor has been

installed, make sure to rotate the compressor drive

shaft several times to properly distribute oil in the

compressor. Compressor damage due to oil slug-

ging can occur if this procedure is not performed.

3. Manually rotate the compressor drive shaft at least

ten (10) revolutions to make sure that no compressor oil

is in the compressor cylinders.

4. Place drive belt onto compressor pulley.

5. Tension compressor drivebelt with idlerpulley. Make

sure to tighten flange nut to secure belt adjustment.

6. Install exhaust pipe (item 15).

7. Remove caps that were placed on hoses and fittings

during the removal process. Using labels placed during

removal, properly secure hoses to compressor.

8. Connect compressor electrical connector to ma-

chine wire harness.

9. Have a certified air conditioning service technician

evacuate the air conditioning system completely, prop-

erly recharge the system with R134a refrigerant and

then leak test the system. A/C system capacity is 1.35

pounds of R134a refrigerant.

10.Lower and secure hood.

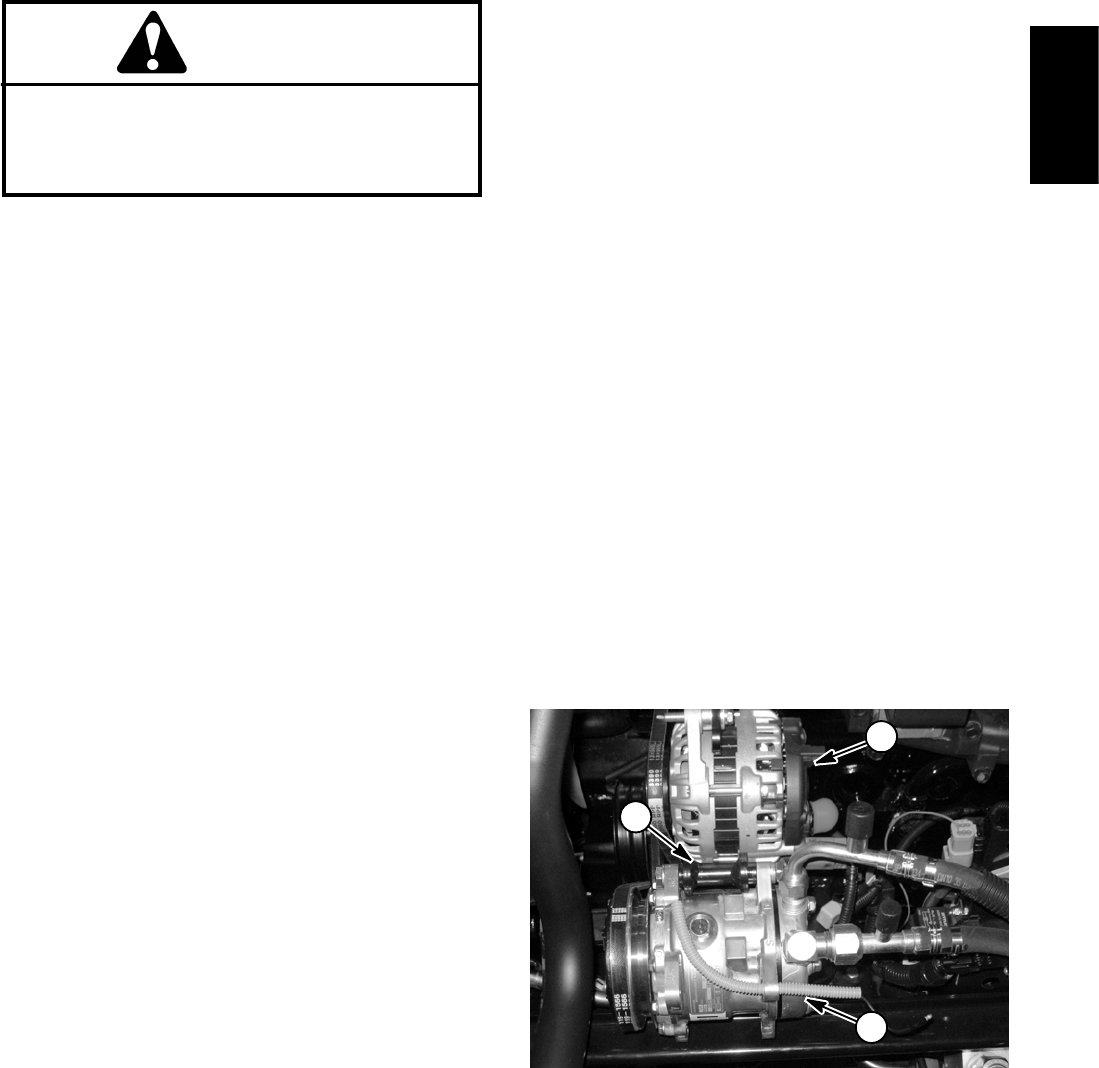

1. A/C compressor

2. Alternator

3. A/C compressor mount

Figure 2

1

2

3

Operator

Cab