Groundsmaster 4000--D/4010--D Cutting DecksPage 8 -- 7

Removal (Fig. 1)

1. Position machine on a clean, level surface. Lower

cutting decks, stop engine, apply parking brake and re-

move key from the ignition switch.

2. Remove spring pin (item 32) that secures damper

(item 30) to cutting deck. Position damper away from

cutting deck.

NOTE: Removal of clevis pin from deck and height--of--

cut chain is easier if deck is lifted slightly.

3. Remove hairpin and clevis pin that secure the

height--of--cut chain to the rear of the cutting deck (Fig.

2).

4. Remove hydraulic motor from cutting deck (see Cut-

ting Deck Motor Removal in the Service and Repairs

Section of Chapter 4 -- Hydraulic System).

5. Remove cap screws, washers and lock nuts secur-

ingball jointmounts(item 14)tocenter deckcastorarms

(Fig. 4).

6. Slide the center cutting deck a way from the traction

unit.

Installation (Fig. 1)

1. Position machine on a clean, level surface. Lower lift

arms, stop engine, apply parking brake and remove key

from the ignition switch.

2. Position the center deck to the lift arms.

3. Align ball jointmounts (item14) toc enter deckcastor

arms and secure with cap screws, washers and lock

nuts (Fig. 4).

NOTE: Installation of clevis pin to deck and height--of--

cut chain is easier if deck is lifted slightly.

4. Install clevis pin and hairpin that secure the height--

of--cut chain to the rear of the cutting deck (Fig. 2).

5. Install hydraulic motor to cutting deck (see Cutting

Deck M otor Installation in the Service and Repairs Sec-

tion of Chapter 4 -- Hydraulic System).

6. Position damper (item 30) to cutting deck bracket

and secure with spring pin (item 32).

7. Lubricate grease fittings on cutting deck and lift arm

assemblies.

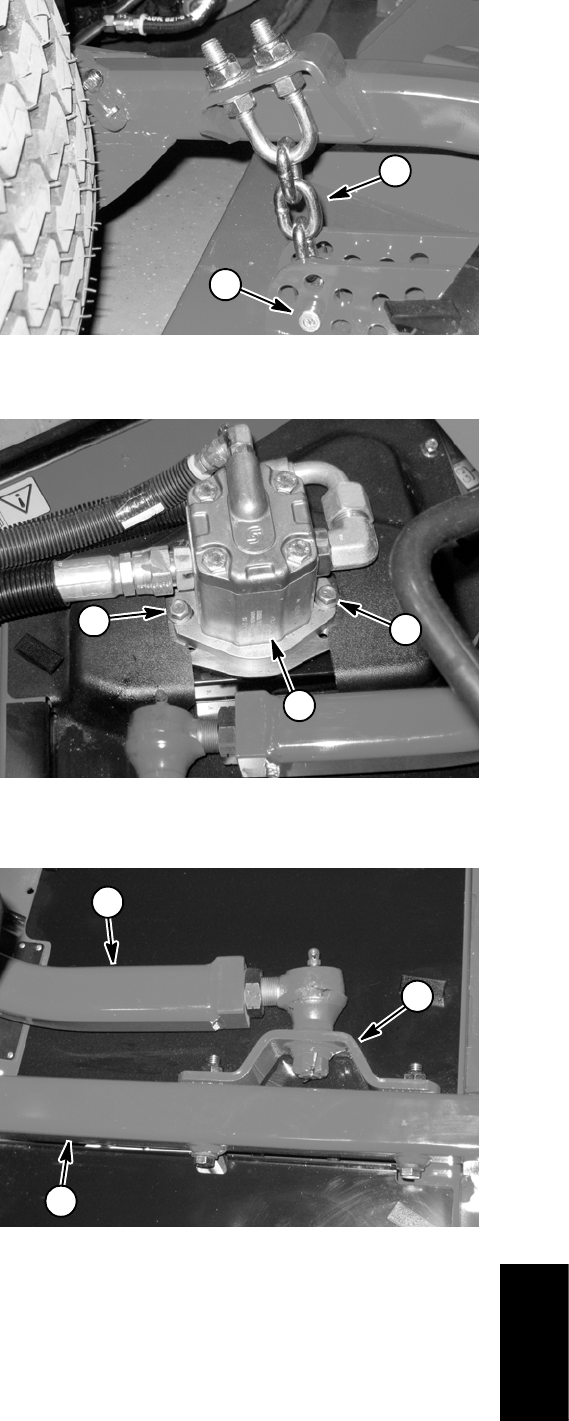

1. Hairpin and clevispin 2. Height--of--cut chain

Figure 2

1

2

1. Flange head screw 2. Hydraulic motor

Figure 3

1

2

1

1. Ball joint mount

2. Lift arm

3. Castor arm

Figure 4

1

2

3

Cutting

Decks