Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 107

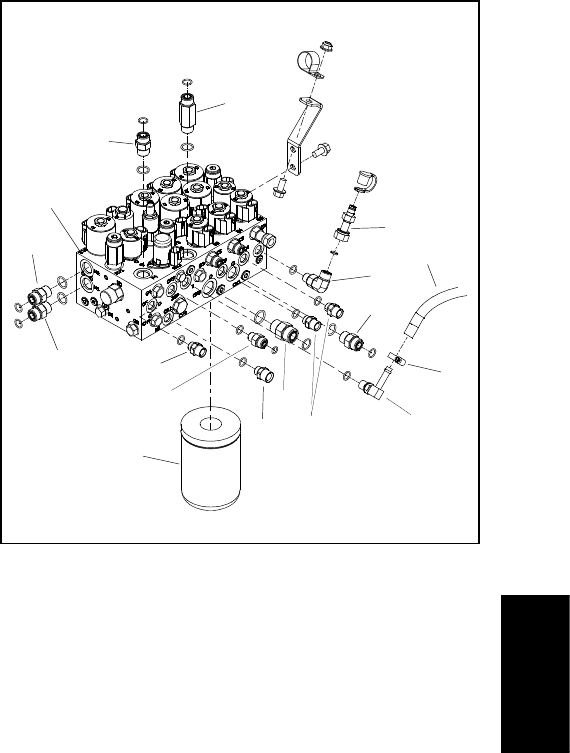

Removal (Fig. 74)

1. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

2. To prevent contamination of hydraulic system during

manifoldremoval, thoroughlyclean exteriorof combina-

tion manifold and fittings.

3. Label all wire harness connectors that attach to

solenoidcoils oncombinationmanifold.Disconnect wire

harness connectors fromsolenoid coilson thecombina-

tion manifold.

4. Disconnect hydraulic lines from combination man-

ifold and put caps or plugs on open hydraulic lines and

fittings.Label disconnectedhydrauliclines forproper re-

assembly.

NOTE: The combination manifold has three (3) studs

on the bottom surface of the manifold used for securing

themanifoldtothemachine.

5. Remove combination manifold from the frame using

Figure 74 as a guide.

6. If hydraulic fittings are to be removed from manifold,

mark fitting orientation to allow correct assembly (Fig.

75). Remove fittingsfrom manifold and discardO--rings.

Installation (Fig. 74)

1. If fittings were removed from manifold, lubricate and

place new O--rings onto fittings. Install fittings into man-

ifold openings using marks made during the removal

process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of t his chapter).

2. Install combination manifold to the frame using Fig-

ure74asaguide.

3. Remove caps and plugs from fittings and hydraulic

lines. Using labels placed during manifold removal,

properly connect hydraulic lines to manifold (see Hy-

draulic Hose and Tube Installation in the General Infor-

mation section of t his chapter).

4. Using labels made duringmanifoldremoval, connect

wire harness connectors to the solenoid coils on the

combination manifold.

5. Make surehydraulic tank isfull. Addcorrect oil if nec-

essary before returning machine to service.

1. Manifold

2. Straight fitting

3. Straight fitting

4. Straight fitting

5. Oil filter

6. Straight fitting

7. Straight fitting

8. Straight fitting

9. Barbed 90

o

fitting

10. Hose clamp

11. Hose

12. 90

o

fitting

13. Test nipple

14. Straight fitting

Figure 75

2

3

6

8

9

10

11

14

1

5

7

12

4

2

2

2

13

Hydraulic

System