Groundsmaster 4000--D/4010--DHydraulic S ystem Page 4 -- 132

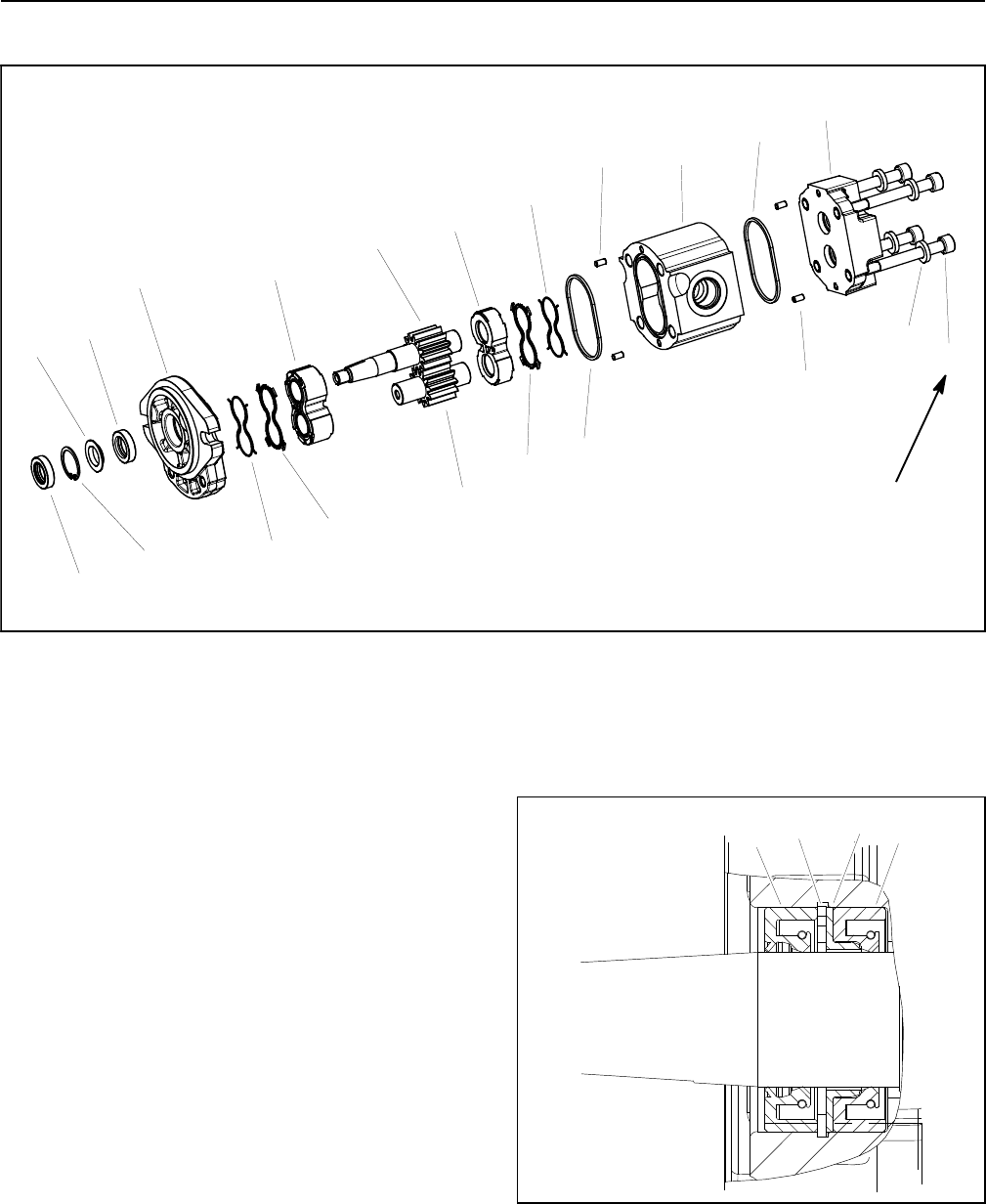

Cutting Deck Motor Service (Casappa)

(45 to 55 N--m)

33 to 40 ft--lb

8

7

4

3

2

6

9

10

11

9

12

13

8

14

16

15

14

1

1. Flange washer

2. O--ring

3. Front flange

4. Dust seal

5. Retaining ring

6. Front wear plate

7. Shaft seal

8. Backup gasket

9. Pressure seal

10. Rear wear plate

11. Body

12. Idler gear

13. Cap screw (4 used)

14. Dowel (4 used)

15. Drive gear

16. Washer (4 used)

17. Rear cover

Figure 99

5

2

17

The Casappa cutting deck motors have similar con-

struction as the cooling fan motor (also a Casappa

brand) used on the Groundsmaster 4000--D and

4010--D. The deck motors have a separate rear cover

(item 17 in Fig. 99) which isa difference from the cooling

fan motor which includes the rear cover with the motor

body. Orientation of thedust seal(item4 in Fig.99) is dif-

ferent in the deck motors than in the cooling fan motor.

For disassembly, inspection and assembly procedures

of the Casappa cutting deck motors, refer to Engine

Cooling Fan Motor Service in this section. When in-

stalling the seals into the front flange in a cutting deck

motor, use the orientation shown in Figure 100.

NOTE: Internal components for a cutting deck motor

are not available separately. Disassemble motor for

cleaning, inspection and seal replacement only.

Figure 100

1

2

3

4

1. Dust seal

2. Retaining ring

3. Flange washer

4. Shaft seal