Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 81

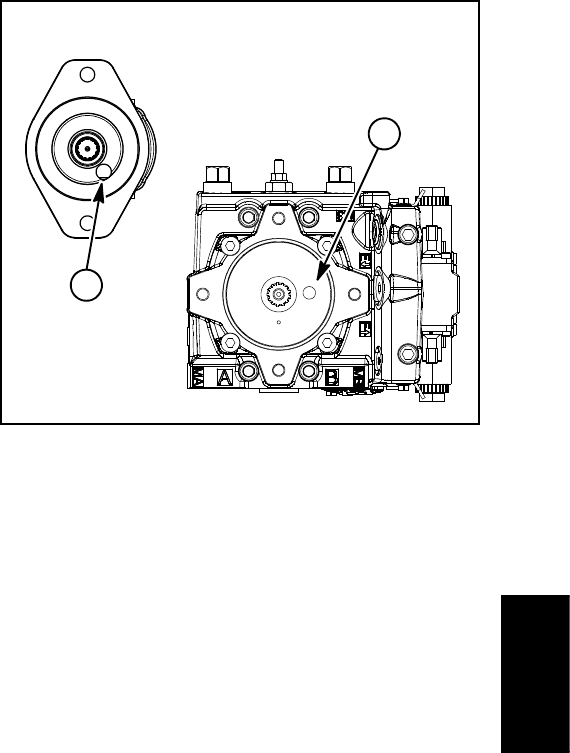

Removal (Fig. 55)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply park ing brake and remove

key from the ignition switch.

2. Raise and support machine to gain access to gear

pump from the underside of the machine.

3. Drain the hydraulic reservoir.

IMPORTANT: Follow all localcodes and regulations

when recycling or disposing hydraulic fluid.

4. To prevent contamination of hydraulic system during

removal, thoroughly clean exterior of pump and fittings.

5. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

6. Disconnect hydraulic lines from gear pump and put

caps or plugs on open hydraulic lines and fittings. Label

disconnected hydraulic lines for proper installation.

IMPORTANT: Dryweight of gear pump is 23 pounds

(10.2 kg).

7. Support gear pump assembly to prevent it from fal-

ling.

8. Remove two (2) cap screws and washers securing

gear pump to piston pump. Lower and remove gear

pump from machine.

NOTE: A case drain exists in the piston (traction) pump

and a suction port is near the input shaft of the gear

pump (Fig. 56). When the gear pump is removed from

the piston pump, plug piston pump case drain hole to

prevent draining the piston pump.

9. Remove O--ring (item 11) from between the gear

pump and piston pump. Discard O--ring.

10.If hydraulic fittings are to be removed from gear

pump, mark fitting orientation to allow correct assembly.

Remove fittings from pump and discard O--rings.

Installation (Fig. 55)

1. If fittings were removed from gear pump, lubricate

and place new O--rings onto fittings. Install fittings into

pump openings using marks made during the removal

process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of t his chapter).

2. Make sure mounting and O--ring sealing surfaces on

the gear pump and piston pump are clean.

3. Apply clean hydraulic oil to gear p ump flange O--ring

(item 11). Place O--ring on the gear pump.

1. Piston pump case drain 2. Gear pump suction port

Figure 56

Remove plugs before installing

gear pump to piston pump

2

1

IMPORTANT: Position gear pump to the piston

(traction)pump sothatthe gearpumpinlet (suction)

ports are facing down.

IMPORTANT: A case drain exists in the piston (trac-

tion) pump and a suction port is near the input shaft

of the gear pump (Fig. 56). Before the gear pump is

installed to the piston pump, make sure that plugs

placed in either of these ports are removed. Failure

to remove plugs will cause excessive pressure in

the pistonpump and damage seals. Also, before se-

curing gear pump to piston pump, fill piston pump

housing with clean hydraulic oil through case drain

hole.

4. Remove plugs that were placed in piston pump case

drainand gearpump suction port.Fill pistonpump hous-

ing with clean hydraulic oil through case drain hole.

5. Position gear pump to the piston (traction) pump so

that the pump inlet ports are facing down.

6. Align gear teeth and slide gear pump input shaft into

piston pump shaft. Secure gear pump to piston pump

with two (2) cap screws and flat washers.

7. Remove caps and plugs from hydraulic lines and fit-

tings. Using labels placed during gear pump removal,

properly install lines to gear pump (see Hydraulic Hose

and Tube Installation in the General Information section

of this chapter).

8. Fill piston pump housing through case drain (90

o

barbed fitting) with new hydraulic oil (Fig. 57). This will

ensure that internal pump components have adequate

lubrication during initial operation.

9. Lower machine to ground.

Hydraulic

System