Groundsmaster 4000--D/4010--D Page 7 -- 25 Chassis

Removal (Fig. 24)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply park ing brake and remove

key from the ignition switch.

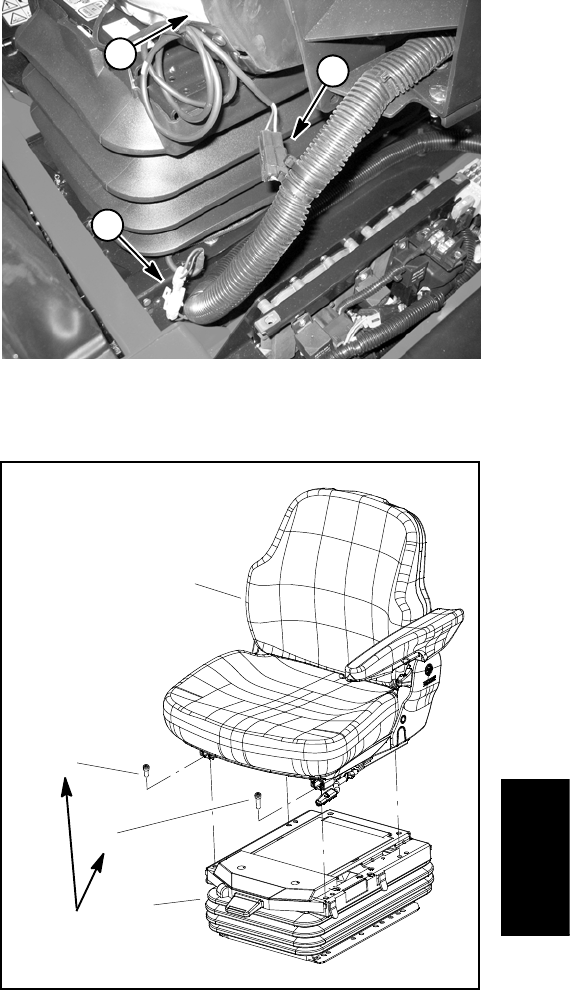

2. Disconnect seat electrical connector from machine

wire harness (Fig. 25).

3. Supportcontrolarm assembly topreventit fromshift-

ing.

4. Remove flange nut (item 4) and carriage screw (item

1) that secure support bracket (item 3) to support chan-

nel (item 2).

5. Removescrew (item 8)that securescontrolarmsup-

port (item 7) to coupler nut (item 9).

6. Remove cap screw (item 5), flat washers (item 6),

spacer (item 10) and seat belt latch (item 21) from seat

and control arm support (item 7).

IMPORTANT: Make sure to not damage the electri-

cal harness, control cable or other parts while mov-

ing the control arm assembly.

7. Carefully move control arm assembly away from

seat.

8. Remove four (4) torx head screws that secure seat

to seat suspension (Fig. 26). Note that the screw near

theseatadjustmenthandle islonger thanthe otherthree

(3) screws.

9. Lift seat from seat suspension and remove f rom ma-

chine.

NOTE: Refer to Operator Seat Suspension in this sec-

tion if seat suspension service is necessary.

Installation (Fig. 24)

1. Carefully position seat to seat suspension.

2. Secure seat to seat suspension with four (4) torx

head screws (Fig. 26). Make sure that longer screw is

positioned near the seat adjustment handle. Torque

screws 18 ft--lb (25 N --m).

IMPORTANT: Make sure to not damage the electri-

cal harness, control cable or other parts while mov-

ing the control arm assembly.

3. Position and secure control arm assembly to seat.

Install all fasteners before fully tightening them.

A. Secure support bracket (item 3) and support

channel (item 2) withflange nut (item 4) and carriage

screw (item 1).

B. Secure control arm support(item 7)tocoupler nut

(item 9) with screw (item 8).

C. Placeflat washer(item 6), seat beltlatch (item21)

and spacer (item 10) between seat and control arm

support (item 7). Secure with cap screw (item 5) an d

second flat washer (item 6).

D. Fully tighten all fasteners t o secure control arm

assembly to seat.

4. Connect seat electrical connector to machine wire

harness (Fig. 25).

1. Operator seat

2. Seat switch connector

3. Suspension connector

Figure 25

1

2

3

1. Seat

2. Suspension assembly

3. Screw (M8x12) (3 used)

4. Screw (M8x16)

Figure 26

2

3

1

4

18 ft--lb

(25 N--m)

Chassis