Groundsmaster 4000--D/4010--DPage 5 -- 60Electrical System

Cutting Deck Position Switches

Three (3) cutting deck position switches are usedon the

Groundsmaster 4000--D and 4010--D. These switches

are located on the traction unit frame (Figs. 80 and 81).

The position switches are powered proximity switches

that incorporate an internal reed switch and a LED. T he

deck position switches are used as inputs for the TEC

controller toprevent deck operation when acutting deck

is raised. The switch sensing plates are attached to the

cutting decklift arms. The positionswitches for front and

side decks are different.

The single front cutting deck position switch is a normal-

ly closed switch. When the front cutting deck is lowered,

the sensing plateon thelift armis awayfrom theposition

switch sothe switch is inits normally closed state. When

the front cutting deck is raised, the sensing plate is

movednearthepositionswitchandtheswitchopens.

The two (2) side cutting deck position switches are nor-

mally open switches. When a side cutting deck is low-

ered, the sensingplate onthe liftarm is nearthe position

switch and the switch closes. When a side cutting deck

israised, thesensingplateis movedaway from theposi-

tion switch so the switch is in its normally open state.

Testing

1. The cutting deck position switches and their circuit

wiring should be tested as aTEC input with the InfoCen-

terDisplay (seeInfoCenter Displayin thischapter).If the

InfoCenter verifies that the position s witches and circuit

wiring are functioning correctly, no further switch testing

is necessary. If, however, the InfoCenter determines

that a position switch and circuit wiring are not function-

ing correctly, proceed with test.

2. Park machine on a level surface, lower cutting

decks, stop engine and apply parking brake.

3. Turn ignition switch to the RUN position (do not start

engine) and check LED on cable end of position

switches (Fig. 80 or 81). Switch LED should be illumi-

nated when the cutting decks are fully lowered.

4. Start engine, fully raise cutting decks and then stop

engine. Then, turn ignition switch to the RUN position

(do not start engine) and check LED on cable end of

position switches. Switch LED should not be illumi-

nated when the cutting decks are fully raised.

5. If a position switch LED did not function correctly:

A. Position cutting deck so sensing plate on the lift

arm is near the position switch (front cutting deck

raised and side cutting decks lowered).

B. Make sure that ignition switch isOFF and discon-

nect the switch connector from wire harness.

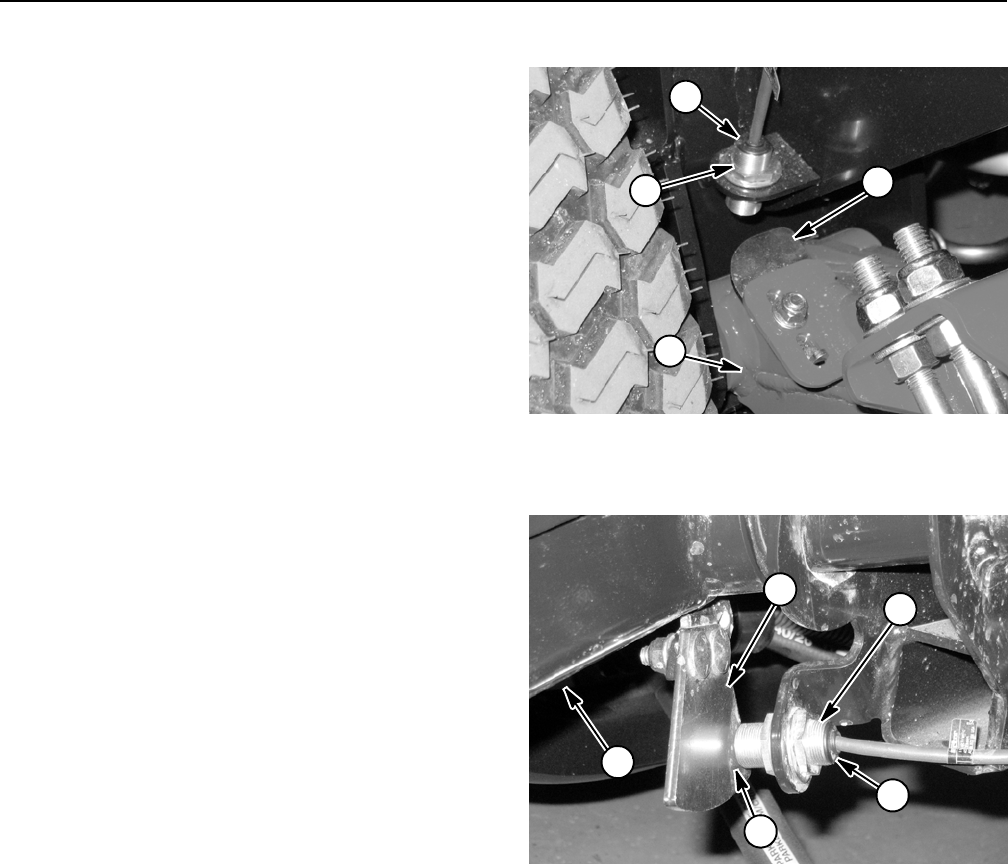

1. Front lift arm

2. Position switch

3. Sensing plate

4. Switch LED

Figure 80

3

1

2

4

1. Side lift arm (RH shown)

2. Position switch

3. Sensing plate

4. Switch LED

5. Clearance

Figure 81

3

1

2

5

4

C. Using a multimeter, verify that wire harness con-

nector terminal for pink wire has 12 VDC when the

ignition switch is RUN.

D. Make sure that clearance between end of posi-

tion switch and sensing plate is from 0.070” to

0.130” (1.8 to 3.3 mm).Ifnecessary,adjustposition

switch (see Cutting Deck Position Switches in the

Adjustments section of this chapter). Recheck

switch operation after adjustment.

E. Ifpink wirehas systemvoltagepresent andgap is

correct but switch LED does not function, replace

position switch.

6. After testing is complete, make sure that position

switch connector is plugged into wire harness.