Groundsmaster 4000--D/4010--DHydraulic System Page 4 -- 88

Installation (Fig. 61)

1. If fittings were removed from piston pump, lubricate

and place new O--rings onto fittings. Install fittings into

pump openings using marks made during the removal

process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of this chapter).

IMPORTANT: To prevent spring coupler damage,

make sure that piston pump is properly supported

anddoesnot putsideload intocoupler duringpump

installation.

2. Carefully raise piston pump into the machine, align

pump input shaft to spring coupler on engine and posi-

tion it to the engine flywheel plate. Support pump to pre-

vent it from producing any side load into coupler and

also to align pilot diameter of pump to flywheel plate

bore.

3. While maintaining pump alignment with spring cou-

pler and flywheel plate, install two (2) cap screws and

washers to secure piston pump to engine.

IMPORTANT: A case drain exists in the piston (trac-

tion) pump and a suction port is near the input shaft

of the gear pump (Fig. 63). Before the gear pump is

installed to the piston pump, make sure that plugs

placed in either of these ports are removed. Failure

to remove plugs will cause excessive pressure in

the piston pumpand damage seals. Also, before se-

curing gear pump to piston pump, fill piston pump

housing with clean hydraulic oil through case drain

hole.

4. Remove plugs that were placed in piston pump case

drainand gear pumps uction port. Fillpistonpump hous-

ing with new hydraulic oil through case drain hole.

5. Install gear pump to piston pump (see Gear Pump in

this section).

6. Using labels placed during pump removal, connect

wire harness connectors to the two (2) solenoid coils on

left side of piston pump.

7. Fill piston (traction) pump housing with new hydraul-

icoil through thecasedrain (90

o

barbedfitting)at thetop

of thepump (Fig.64). This willensure that internalpump

components have adequate lubrication during initial op-

eration.

8. Remove plugs and caps from disconnected hydrau-

lic lines and fittings of the pump assembly. Install hy-

draulic lines to correct location on gear and piston

pumps (see Hydraulic Fitting Installation and Hydraulic

Hose and Tube Installation in the General Information

section of this chapter).

9. Lower machine to ground.

10.Install new hydraulic filter and fill hydraulic reservoir

with correct oil.

IMPORTANT: Refer to Traction Circuit Component

Failure in the General Information section of this

chapter forinformation regarding theimportance of

removing contamination from the traction circuit.

11.Prime hydraulic pumps (see Priming Hydraulic

Pumps in this section).

12.Properly fill hydraulic system (see Charge Hydraulic

System in this section).

13.Stop e ngine and check for hydraulic oil leaks. Check

hydraulic reservoir oil level.

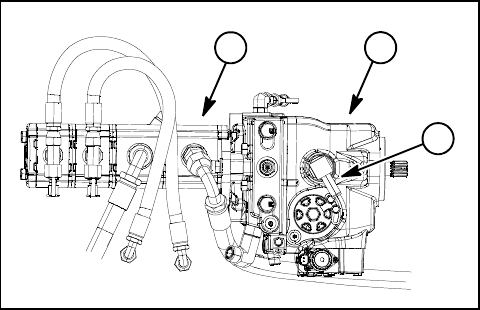

1. Piston (traction) pump

2. Gear pump

3. Piston pump case drain

Figure 64

2

3

1