9-4-2 PISTON AND PISTON RING

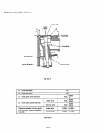

(1) If a ring expander is not available, set the ring joint at the first land of the piston, as shown

in Fig. 9-4-4. Then, open the joint wide so that the ring can be slid into the fegular groove.

Note: Be careful not to twist or expand each ring too excessively. The oil ring is fitted onto the

piston, followed by the second ring and top ring.

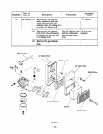

F&. 9-43

Top Ring

Second Ring

Oil Ring

Fig. 9-4-4

(2) The connecting rod is joined to the

piston with the piston pin.

Note: Prior to assembly, apply sufficient lub-

ricating oil, to the connecting rod

minor edge.

Note: Be sure to secure the clips to both sides

of the piston pin.

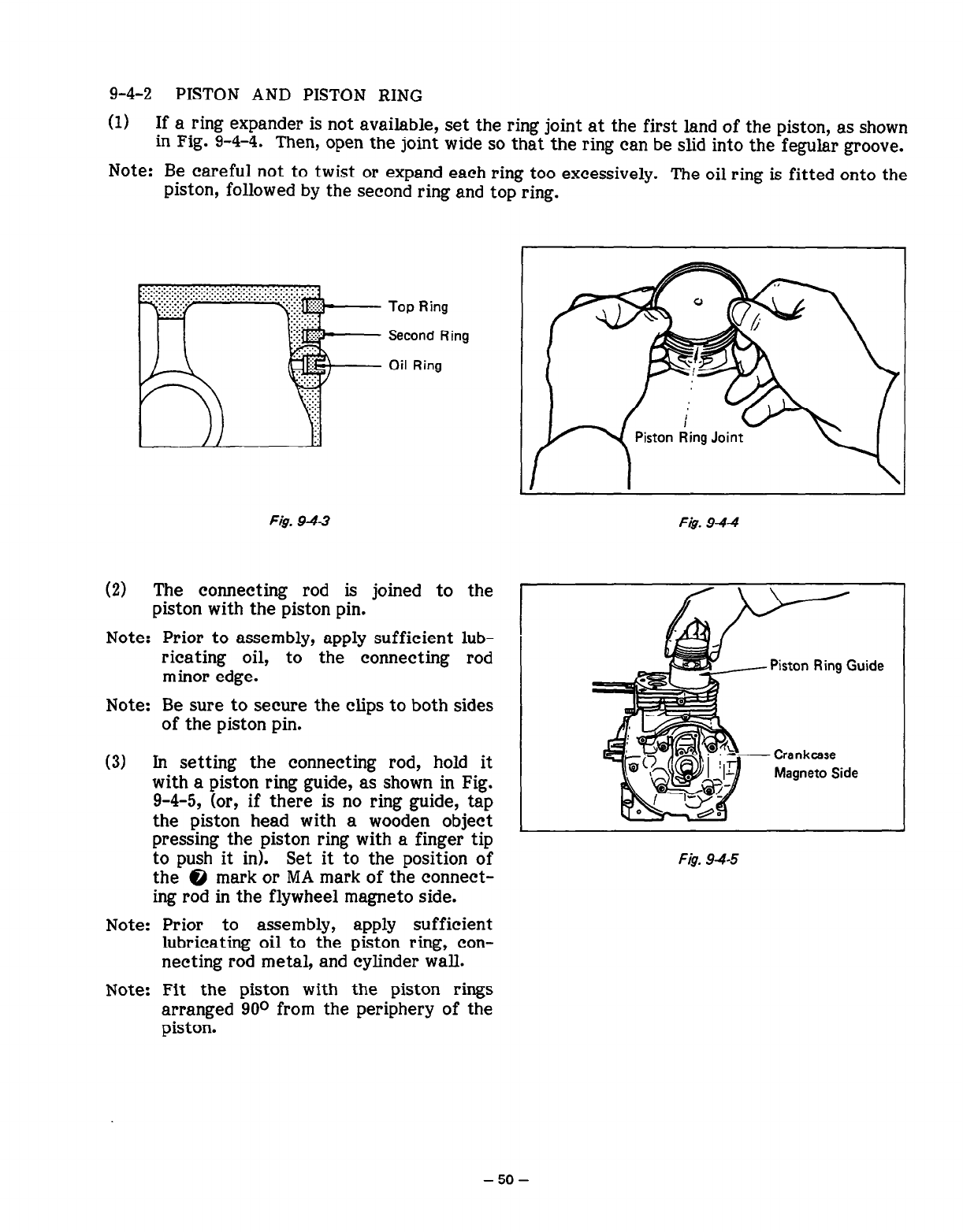

(3) In setting the connecting rod, hold it

with a piston ring guide, as shown in Fig.

9-4-5, (or, if there is no ring guide, tap

the piston head with a wooden object

pressing the piston ring with a finger tip

to push it in).

Set it to the position of

the @ mark or MA mark of the connect-

ing rod in the flywheel magneto side.

Note: Prior to assembly, apply sufficient

lubricating oil to the piston ring, con-

necting rod metal, and cylinder wall.

Note: Fit the piston with the piston rings

arranged 90* from the periphery of the

piston.

Piston Ring Guide

F&T 94-5

-50-