HAssembly sequence and precautions

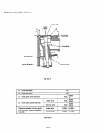

9-4-l CRANKSHAFT

(1)

Fit the crankshaft oil seal guide onto the

crankshaft tip and assemble it with the

crank case as shown in Fig. 9-4-l.

No

te: When the oil seal guide is not used, be

careful not to damage the oil seal lip.

(2)

(3)

Mount the woodruff key (for the mag-

neto).

Dimentional tolerance of the crankpin.

.Crankshaft

Crankcase

Oil Seal Guide

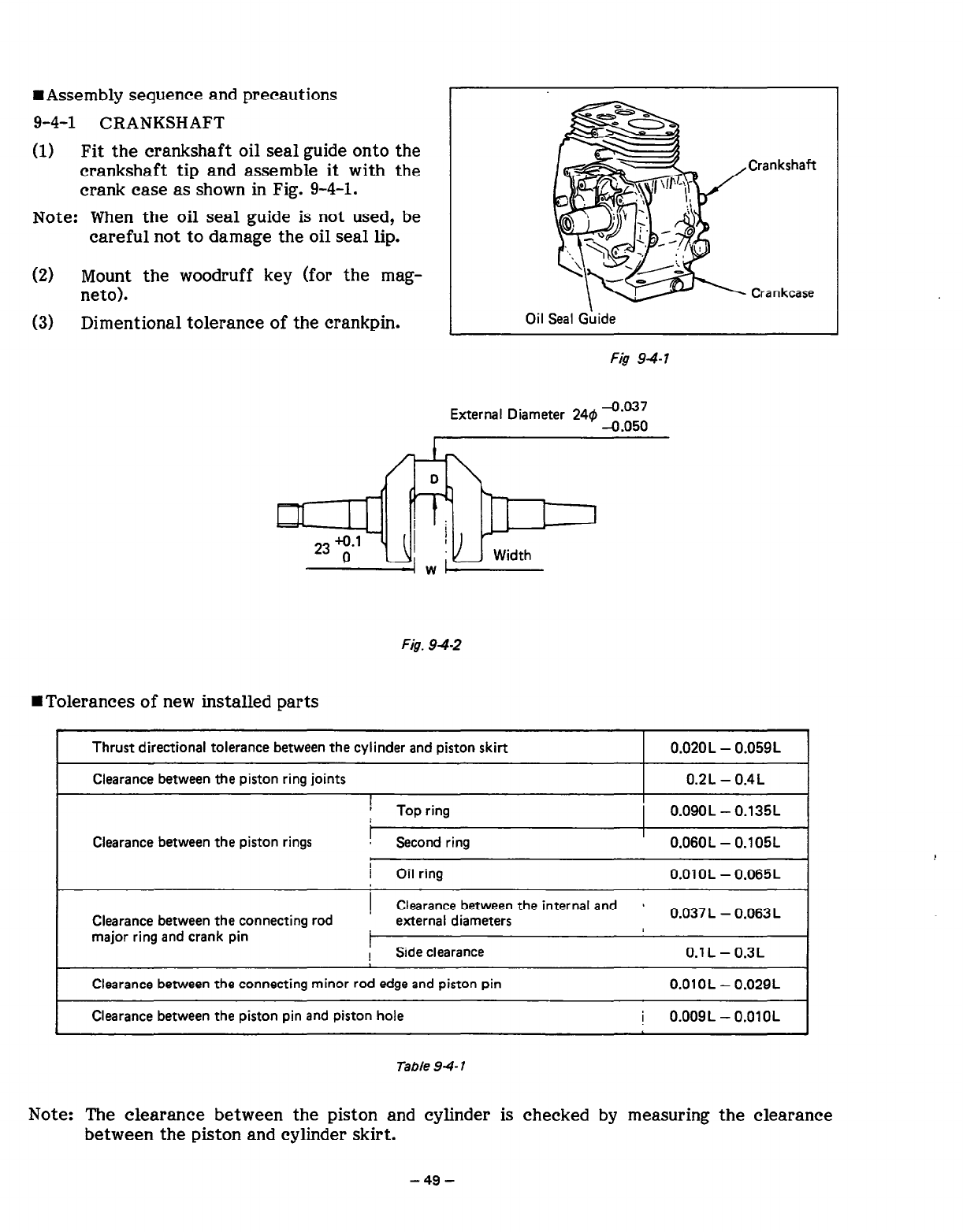

External Diameter 24~) Z-03;

I

I

Fig. 942

WTolerances of new installed parts

I

Thrust directional tolerance between the cylinder and piston skirt

0.02OL - 0.059L

Clearance between the piston ring joints

0.2L - 0.4L

1

i Top ring 0.09OL - 0.135L

Clearance between the piston rings

! Second ring 0.060L - 0.105L

I

/ Oil ring O.OlOL - 0.065L

Clearance between the connecting rod

major ring and crank pin

1 Clearance between the internal and

s

’ external diameters

0.037 L - 0.063 L

1 Side clearance 0.1 L - 0.3L

Clearance between the connecting minor rod edge and piston pin

O.OlOL - 0.029L

Clearance between the piston pin and piston hole

i

0.009L - 0.01 OL

Table 94 7

Note: The clearance between the piston and cylinder is checked by measuring the clearance

between the piston and cylinder skirt.

-49-