Troubleshooting and Maintenance 5‐3MN2408

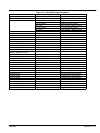

Table 5‐2 Troubleshooting Guide (Digital Controller Only)

Problem Possible Cause Remedy

Controller does not power up even with

correct DC power applied

Wiring Mistake

Overload Condition

Check that there are no wiring errors/short circuits connected to the

controller.

The MEC 20 contains an electronic fuse that trips when an overload

condition exists and does not reset until the supply voltage is

removed and reapplied after the overload condition is corrected.

LCD Display cannot be viewed Microprocessor failure

Improper Supply Voltage

Improper contrast adjustment

Check that the controller's microprocessor is running by observing a

red flashing “watchdog” LED on the rear of the PCB. Replace

controller if failed.

Check DC supply voltage at terminals B+ & B- (10-30VDC).

Adjust LCD contrast potentiometer (R115) on rear of PCB for best

display.

Controller cannot be “Reset” Engine not stopped

Controller not in OFF mode

Verify the engine is at a complete stop before trying to reset.

Set the controller to the OFF mode before trying to reset.

No “RUN” output signal “Shutdown Faults” not reset

Engine speed not detected at cranking

Run Contact not closing (terminals #18 &

#19)

All shutdown faults must be reset (red shutdown LED must be off).

Engine speed signal must be detected (speed signal green LED on)

during cranking if the “run-output fail safe” feature is enabled. Verify

correct magnetic pickup signal at cranking (2.0VAC min. during

cranking).

Check that the RUN output LED (on the rear of the PCB) is on.

If yes, verify relay contact operation on terminals #18 & #19.

Replace controller if failed.

Overspeed shutdown occurs at normal

speed

Controller programmed values are wrong

or controller has failed.

Verify the controller programmed values are correct for the number

of flywheel teeth, nominal RPM, and overspeed setpoint

percentage. Replace controller if failed.

Voltage or current metering is incorrect Controller programmed values are wrong

Ground is missing

Analog input needs to be calibrated

Voltage sensing wiring mistake

Verify the controller programmed values are correct for the voltage

sensing PT ratio and/or current sensing CT ratio.

Verify that the battery supply DC negative conductor is properly

grounded to the engine block (i.e. to a common ground point).

Verify that the controller's analog input is properly calibrated.

Verify the voltage sensing wiring connection to the MEC 20 matches

power distribution type.

Note: standard direct voltage connection requires that the

generators neutral is solidly grounded.

Engine temperature or oil pressure

display is incorrect

Analog input needs to be calibrated

Failed engine sensor

Ground is missing

Verify that the controller's analog input is properly calibrated.

Verify engine sensors.

Note: engine sensors must be factory supplied units only.

Verify that the battery supply DC negative conductor is properly

grounded to the engine block (i.e. to a common ground point).

Engine temperature or oil pressure

displays 9999

OR

Engine alarms are ON for high engine

temperature or low oil pressure when

engine is operating properly

Sending unit is disconnected (open

circuit)

Defective sending unit

Wrong Temp or pressure calibration

Verify the sending units wiring to controller terminals #37 & #38 (i.e.

wiring is not open or shorted).

Verify the engine mounted senders have correct resistance values

for corresponding input temperature or pressure.

Verify calibration.

Keypad Buttons (switches) do not

operate.

Keypad not connected to controller Verify the interconnecting ribbon cable between the lexan faceplate

and main printed circuit board is correctly connected.

Replace controller if failed.