Operation 4‐29MN2408

Engine Temperature & Oil Pressure Calibration

To accurately calibrate the controller's temperature sensor, an external temporary engine mounted

temperature gauge is required. The external temperature gauge should be connected as close as possible

to the temperature sender.

To accurately calibrate the controller's pressure sensor, an external temporary engine mounted pressure

gauge is required. The external pressure gauge should be connected as close as possible to the pressure

sender.

ENGINE TEMP

127 955C

Displays the type of calibration function.

Displays the calibration correction factor number (0-255) used to obtain the correct Temperature or Pressure reading.

Displays the actual temperature or pressure measurement shown on the display menus.

This reading may be calibrated higher or lower by changing the correction factor number.

Engine Temperature The engine temperature analog circuit must be calibrated with the engine temperature sender mounted on the engine.

Connect a temporary engine mounted temperature gauge of suitable accuracy and start the engine. After the engine

reaches normal operating temperature, enter the programming mode and scroll to the “Engine Temperature Offset”

calibration point. Use the INCREMENT or DECREMENT push-buttons to adjust the correction factor number while

observing the displayed temperature. Adjust the correction factor number to obtain the identical temperature reading as

measured with the external temperature gauge. With the correct temperature displayed, press the “Enter” push-button to

accept the correction factor number. Record the correction factor on the programming sheet for future reference.

Oil Pressure Connect a temporary engine mounted pressure gauge of suitable accuracy and start the engine. After the engine

reaches normal operating pressure and temperature, enter the programming mode and scroll to the “Engine Pressure

Offset” calibration point. Use the INCREMENT or DECREMENT push-buttons to adjust the correction factor number

while observing the displayed pressure. Adjust the correction factor number to obtain the identical pressure reading as

measured with the external pressure gauge. With the correct pressure displayed, press the “Enter“ push-button to

accept the correction factor. Record the correction factor on the programming sheet for future reference.

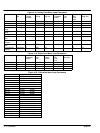

Engine

Temperature

Sender

Resistance

Oil

Pressure

Sender

Resistance

5F 5C Ohms KPA PSI Ohms

392 200 20 1034 150 38

374 190 24 965 140 42

356 180 28 896 130 48

338 170 33 827 120 54

320 160 39 758 110 62

302 150 46 689 100 70

284 140 55 621 90 79

266 130 65 552 80 89

248 120 76 483 70 101

230 110 90 414 60 114

212 100 106 345 50 127

194 90 147 276 40 142

176 80 197 207 30 160

150 70 290 138 20 183

140 60 426 69 10 206

122 50 622

104 40 952

86 30 1486

68 20 2322

50 10 3644

32 0 6284

Note: Sender resistance data shown are for Oil Pressure Sender p/n-003654 (Thompson p/n), Manufacturer- Datcon, p/n

102227. Datcon Sender must be used with MEC software version 1.81 or greater (previous software versions cannot be

used).