OPERATION

Saber Operation Section 3-11

©2011 Alamo Group Inc.

OPERATION

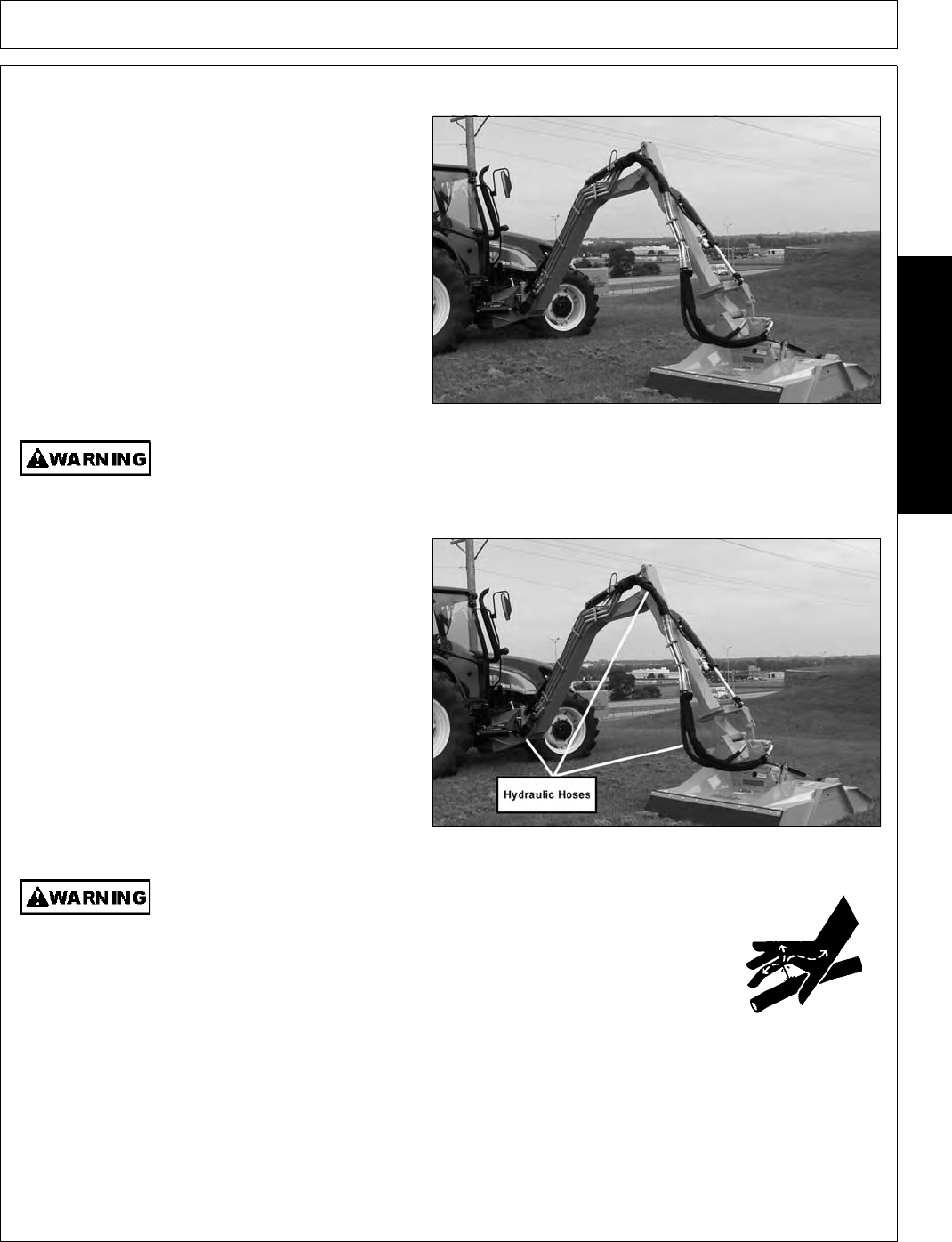

BOOM ARM ASSEMBLY

• Inspect condition of each arm section weldment

• Ensure all pins are in place.

• Ensure all bolts, nuts and rollpins are properly

installed.

• Check condition of bushings at boom pivot

points and hydraulic cylinder tangs.

• Ensure each hydraulic cylinder is installed and

retained correctly. Ensure the proper size pins

are used to retain the cylinders in place and are

secured properly. OPS-B- 0022_D

Never attempt to lubricate, adjust, or remove material from the Implement while it is in

motion or while tractor engine is running. (SG-20)

HYDRAULIC LINE INSPECTION

• Check for hydraulic leaks along hoses,

cylinders and fittings. IMPORTANT: DO NOT

use your hands to check for oil leaks. Use a

piece of heavy paper or cardboard to check for

hydraulic oil leaks.

• Inspect the condition of the valve mounting.

• Ensure fittings are properly connected.

OPS-B- 0023_D

Do not operate this Equipment with hydraulic oil or fuel leaking. Oil

and fuel are explosive and their presence could present a hazard. Do

not check for leaks with your hand! High-pressure oil streams from

breaks in the line could penetrate the skin and cause tissue damage

including gangrene. To check for a hose leak, SHUT the unit ENGINE

OFF and remove all hydraulic pressure. Wear oil impenetrable gloves,

safety glasses and use Cardboard to check for evidence of oil leaks. If

you suspect a leak, REMOVE the HOSE and have it tested at a Dealer.

If oil does penetrate the skin, have the injury treated immediately by a

physician knowledgeable and skilled in this procedure.

(SG-15)