MAINTENANCE

Saber Maintenance Section 4-13

©2011 Alamo Group Inc.

MAINTENANCE

GREASING GROUND ROLLER SHAFT-FLAIL

Locate grease zerks on each end of roller tube at lower end of head. Normal conditions require one or two

pump in each bearing, using Lithium-Complex Extreme Pressure grease conforming to NLGI2-ISO 320

specifications. This is to be done with a standard grease gun daily or at 8 hour intervals. CAUTION: Over

greasing may cause premature seal failure.

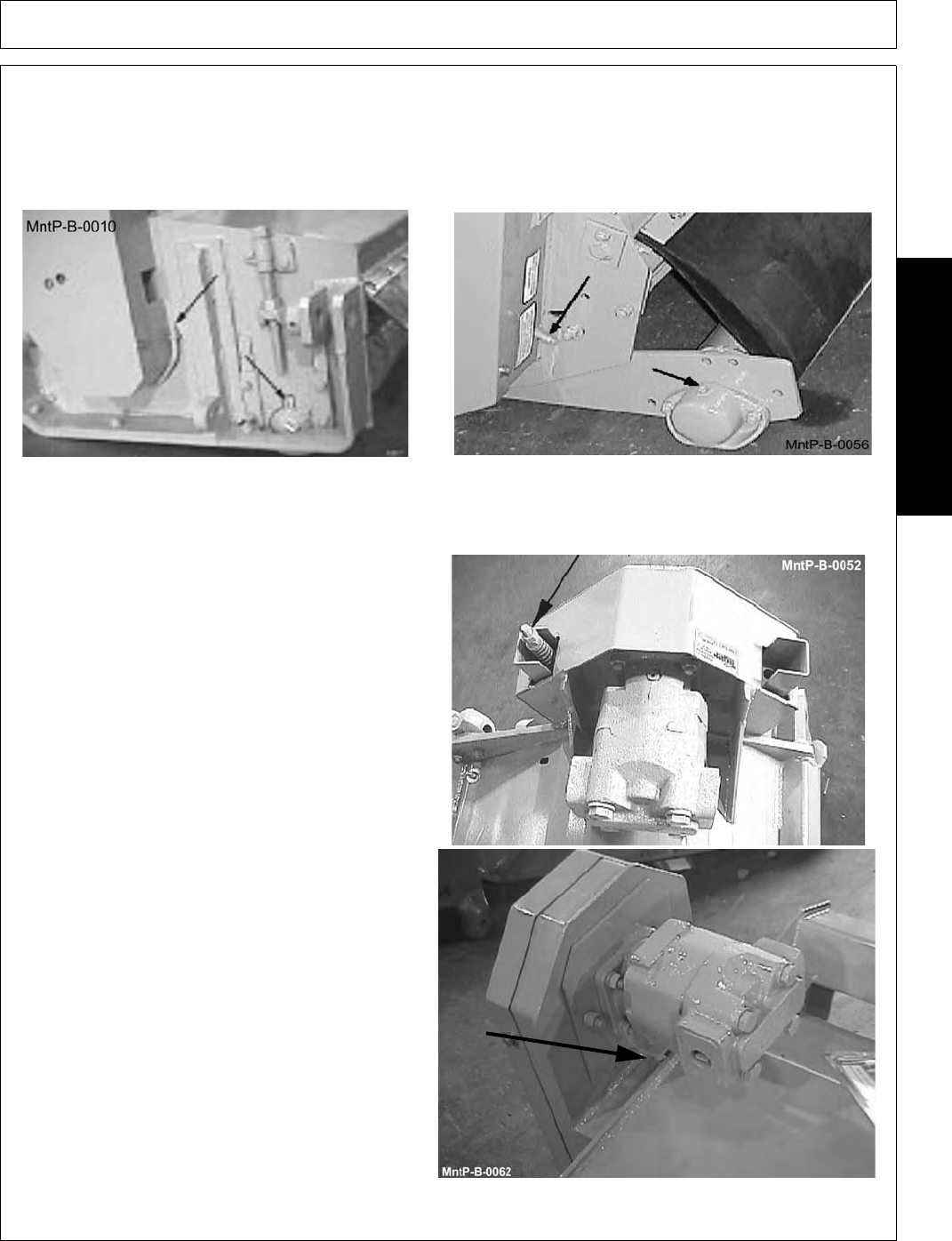

ADJUSTING/CHECKING BELT TENSION

To adjust belt tension or replace belts on flail cutter

head, remove four bolts that secure belt to cover

and remove cover. The hex nuts shown below can

be adjusted to increase/decrease the belt tension

as needed. (NOTE: Location of adjustment nuts

may vary on flail cutter heads.) Be sure to replace

the belt cover BEFORE operating mower!

BOOM FLAIL

SABER FLAIL

SABER FLAIL

BOOM FLAIL