OPERATION

B-10 B-10

BULLDOG® 140

No one can learn to weld simply by reading about it.

Skill comes only with practice. The following pages will

help the inexperienced welder understand welding and

develop his skill. For more detailed information, order a

copy of the book “New Lessons in Arc Welding.” (See

Book Division section at rear of manual).

The operator’s knowledge of arc welding must go

beyond the arc itself. He must know how to control the

arc, and this requires a knowledge of the welding cir-

cuit and the equipment that provides the electric cur-

rent used in the arc. Figure 3 is a diagram of the weld-

ing circuit. The circuit begins where the electrode cable

is attached to the welding machine and ends where the

work cable is attached to the machine. Current flows

through the electrode cable to the electrode holder,

through the electrode holder to the electrode and

across the arc. On the work side of the arc, the current

flows through base metal to the work cable and back to

the welding machine. The circuit must be complete for

the current to flow. To weld, the work clamp must be

tightly connected to clean base metal. Remove paint,

rust,etc. as necessary to get a good connection.

Connect the work clamp as close as possible to the

area you are welding. Avoid allowing the welding circuit

to pass through hinges, bearings, electronic compo-

nents or similar devices that can be damaged.

The electric arc is made between the work and the tip

end of a small metal wire, the electrode, which is

clamped in a holder that is held by the welder. A gap is

made in the welding circuit (see Figure 3) by holding

the tip of the electrode 1/16 - 1/8” (1.6-3.2mm) away

from the work or base metal being welded. The elec-

tric arc is established in this gap and is held and moved

along the joint to be welded, melting the metal as it is

moved.

Arc welding is a manual skill requiring a steady hand,

good physical condition, and good eyesight. The oper-

ator controls the welding arc and, therefore, the quali-

ty of the weld made.

What Happens in the Arc?

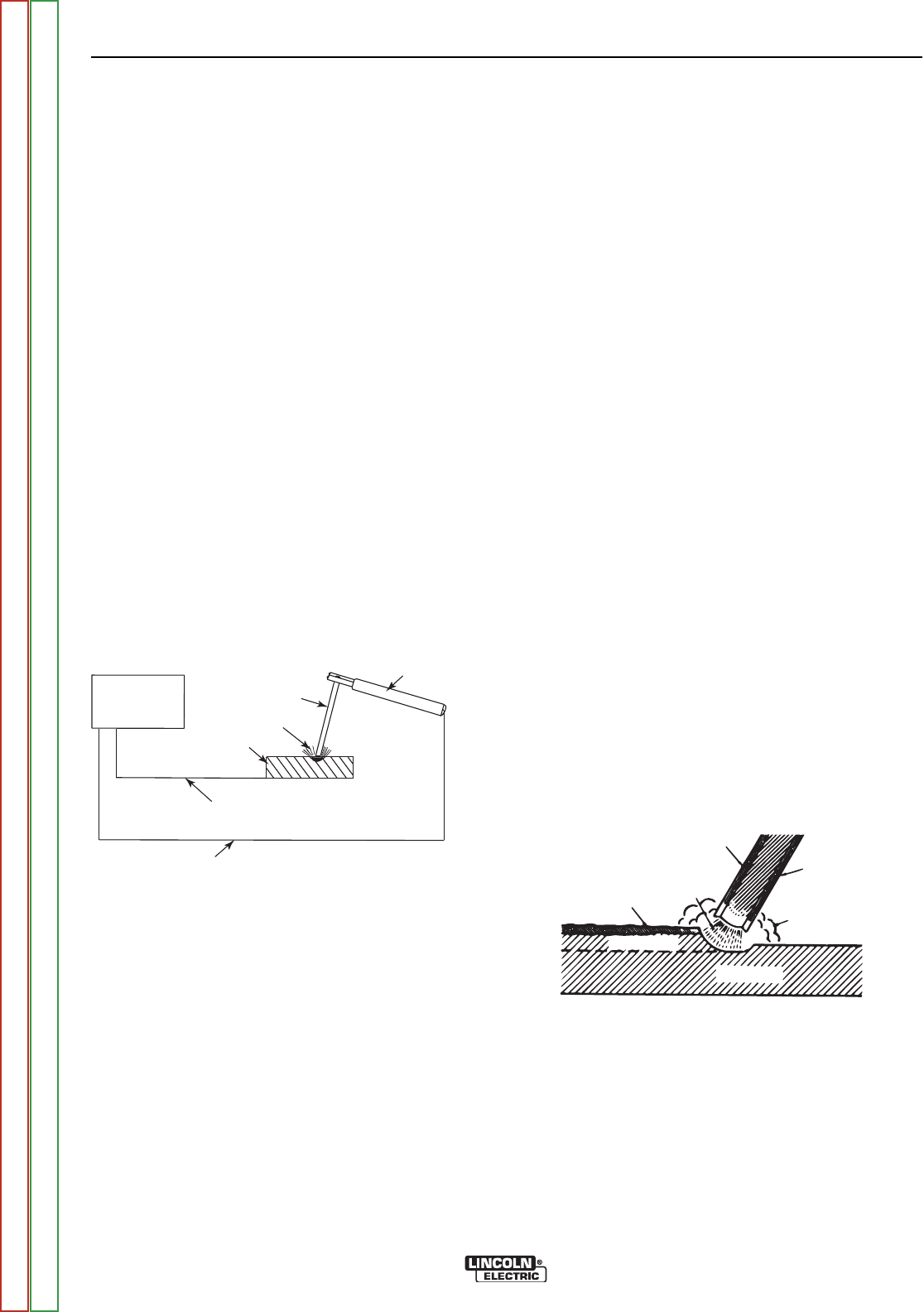

Figure 4 illustrates the action that takes place in the

electric arc. It closely resembles what is actually seen

during welding.

The “arc stream” is seen in the middle of the picture.

This is the electric arc created by the electric current

flowing through the space between the end of the elec-

trode and the work. The temperature of this arc is

about 6000°F (3300°C) which is more than enough to

melt metal. The arc is very bright, as well as hot, and

cannot be looked at with the naked eye without risking

painful and possibly permanent injury. A very dark lens,

specifically designed for arc welding must be used with

the handshield or headshield whenever viewing the

arc.

The arc melts the base metal and actually digs into it,

much like water through a garden hose nozzle digs into

the earth. The molten metal forms a pool or crater and

tends to flow away from the arc As it moves away from

the arc, it cools and solidifies. Slag forms on top of the

weld to protect it during cooling.

Covering

Electrode

Shielding Gases

Arc

Solidified Slag

Weld Metal

Base Metal

FIGURE 4 - The welding arc.

ARC

WORK CABLE

WORK

ELECTRODE CABLE

ELECTRODE HOLDER

ELECTRODE

WELDING MACHINE

AC OR DC POWER

SOURCE AND

CONTROLS

FIGURE 3 - The welding circuit for (Stick) shielded metal arc welding.FIGURE 3 - The welding circuit for (Stick) shielded metal arc welding.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC