TP-5695 12/936-8 Installation

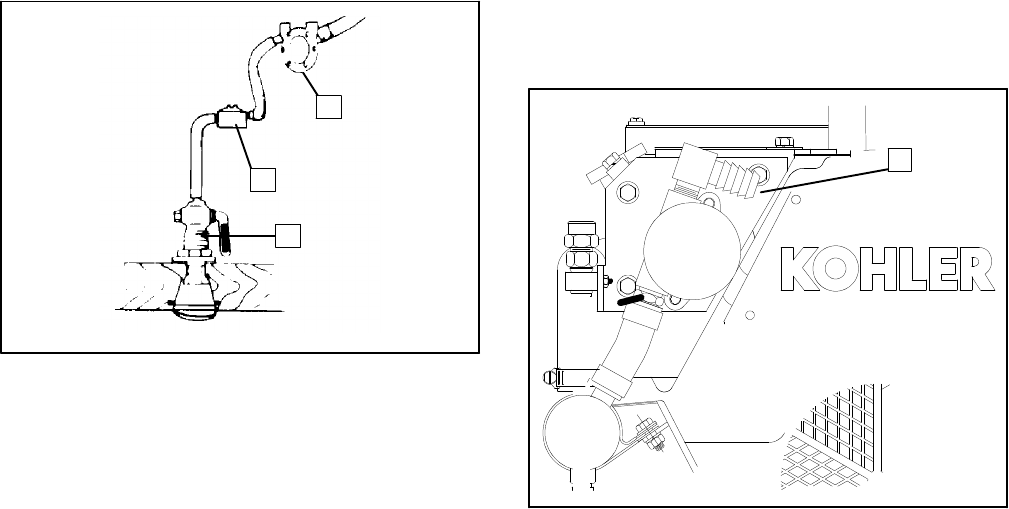

A seawater strainer of sufficient capacity should be

mounted to the seacock or permanent structure at a

point not higher than the seawater pump. The strainer

should be accessible for servicing. See Figure 6-13 for a

typical installation. The optional Kohler seawater

strainer is threaded for 1/2 NPT fittings.

1

2

3

1-789

1. Seawater Pump

2. Seawater Strainer

3. Seacock

Figure 6-13. Seawater Strainer

NOTE

Some seawater strainers include seacock and intake

thru-hull strainer.

Waterlines from the seacock to the engine-driven

seawater pump can be copper tubing or flexible hose. A

flexible section of hose is used for the actual connection

to the seawater pump to allow vibrational motion of the

generator set during operation. The hose should have

an inside diameter of 3/4 in. (19 mm). Copper line should

be supported within 4 in. (102 mm) of its connection to

the flexible section.

NOTE

A 5/8 in. (16 mm) waterline hose can be substituted for

the recommended 3/4 in. waterline hose.

Piping should be kept straight and as short as possible.

See Figure 6-14 for the seawater connection to the

seawater pump inlet. The seawater outlet is combined

with engine exhaust gases. (On sound shielded units, a

small section of molded hose is required for the

seawater inlet connection.)

1

ADV-5792-D

1. 3/4 in. Seawater Pump Inlet

Figure 6-14. Seawater Inlet Connection

Closed/Heat Exchanger

A closed, heat exchanger cooling system, the best

alternative for most applications especially if craft is to

be operated in salt waters or waters with high silt

content, is provided as part of the generator set.

Service accessibility must be provided for the heat

exchanger pressure cap. See Figure 6-15.