TP-5695 12/933-14 Scheduled Maintenance

Flushing and Cleaning

If required, flush coolant from generator set. To properly

flush coolant, obtain Kit #267999 and use the following

procedure:

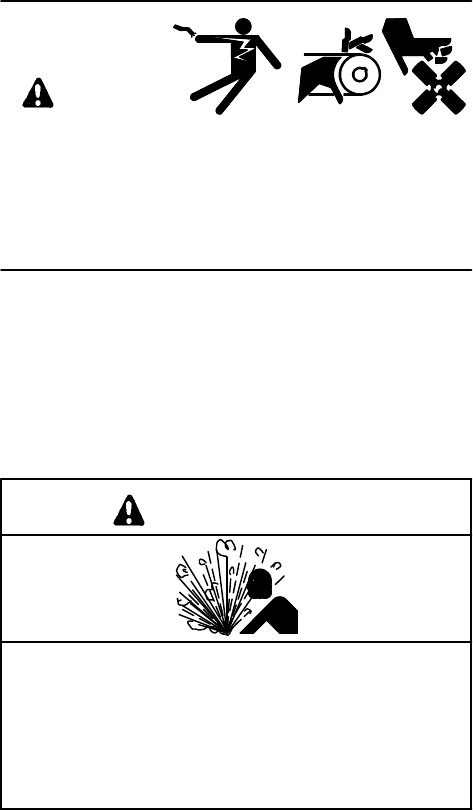

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Disconnect battery cables (remove negative

lead first and reconnect it last) to disable generator set

before working on any equipment connected to

generator. The generator set can be started by remote

start/stop switch unless this precaution is followed.

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing pressure cap stop generator,

allow to cool and loosen pressure cap to relieve

pressure.

Hot coolant can cause severe injury or death. Allow

engine to cool and release pressure from cooling

system before opening pressure cap. To release

pressure, cover the pressure cap with a thick cloth then

turn it slowly counterclockwise to the first stop. After

pressure has been completely released and the engine

has cooled, remove cap. If generator set is equipped

with a coolant recovery tank, check coolant level at tank.

1. Disconnect the battery, negative lead first.

2. With engine cooled, remove the air-bleed screw

and the high water temperature safety shutdown

switch from the thermostat housing.

3. Connect kit hose fittings to the engine. Install kit

hoses to fittings (if not already done).

4. Connect a garden hose to the female connector of

large kit hose. Place the free end of the small kit

hose in a 1--2 gal. (min.) bucket.

NOTE

Heat exchanger pressure cap MUST be installed.

5. Turn on water supply to flush coolant from engine

block. Turn off water supply when clean water is

observed coming from hose in bucket.

6. Disconnect garden hose. Place free end of large kit

hose into bucket and connect an air hose to the free

end of the smaller kit hose. Apply air pressure (40

psi [276 kPa] min.) until water stops flowing from kit

hose in bucket. This will remove about 16 fl. oz.

(0.47 L) of water from engine block.

NOTE

Engine coolant capacity is 23 fl. oz. (0.68 L).

NOTE

Some small air compressors may not maintain

pressure under the required flow conditions. In

these cases, it is recommended that the end of the

kit hose in the bucket be closed off momentarily

until pressure is allowed to build up. After pressure

has accumulated, open end to allow water to flow

into bucket. Repeat closing and opening end of kit

hose, as required.

7. Remove kit hoses with hose fittings from engine.

8. Apply pipe sealant to threads of high water

temperature safety shutdown switch and install

switch in thermostat housing. Reconnect wiring

harness lead to switch.

9. Apply pipe sealant to the air-bleed screw and install

screw into engine. Do not final tighten!

10. Remove cap of coolant overflow bottle and pour

contents into a suitable container. Reinstall bottle

on unit.

11. Add fresh coolant to coolant overflow bottle. A

solution of 50% ethylene glycol and 50% clean,

softened water is recommended to inhibit rust/

corrosion and provide freezing protection. Fill to

MIN mark. Install coolant overflow bottle cap.

12. Remove heat exchanger pressure cap and add

about 5 fl. oz. (0.15 L) of clean, softened water.

Then fill remainder of engine with straight coolant

(100%) until level is just below the overflow tube

opening. Final tighten the air-bleed screw when

coolant, free of air bubbles, starts to flow. Install the

heat exchanger pressure cap.