TP-5695 12/933-22 Scheduled Maintenance

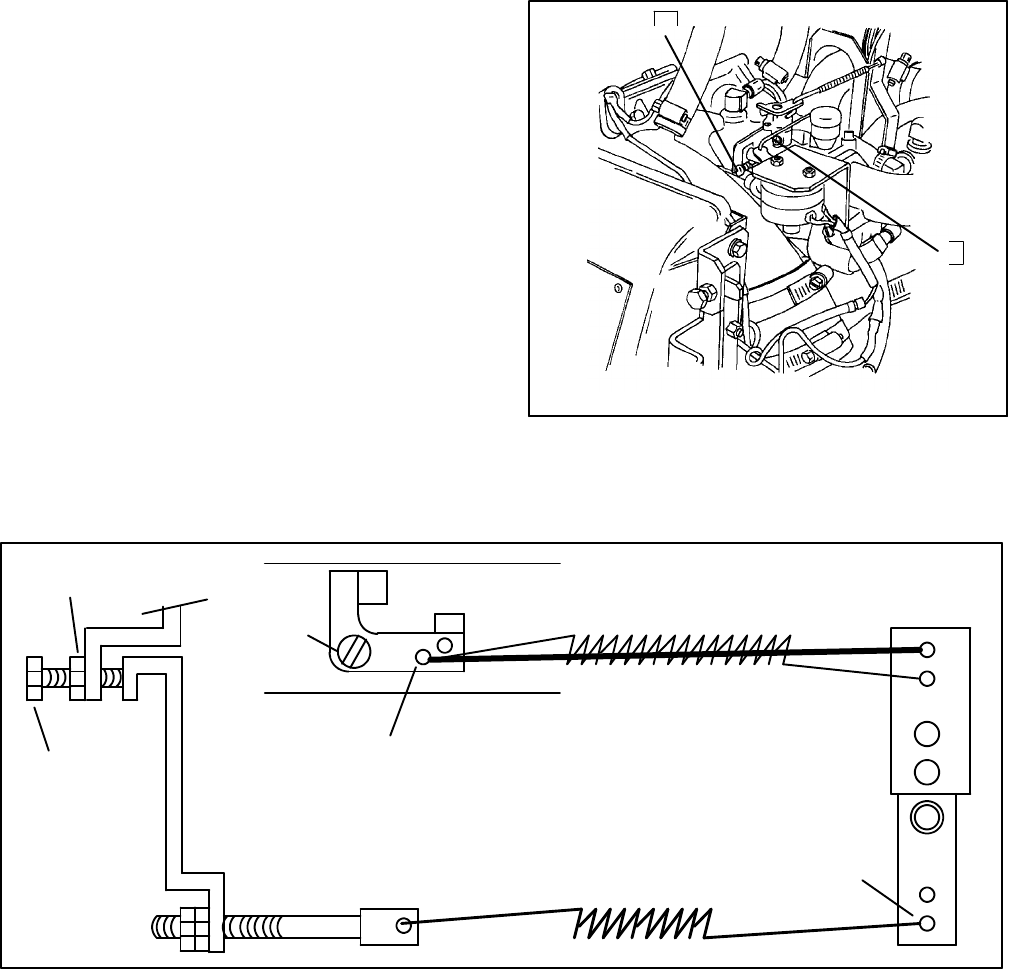

Governor

The gear-driven centrifugal type governor serves to

keep engine speed constant by automatically adjusting

the amount of fuel supplied to the engine according to

changes in load.

Lubrication

Lubricate governor linkage at the specified interval

using white lithium grease or lubriplate.

Governor Adjustment

The gear-driven centrifugal type governor serves to

keep engine speed constant by automatically adjusting

the amount of fuel supplied to the engine according to

changes in load. No regular service is required on the

unit. The governor is adjusted during run-in at the

factory and further adjustment should not be needed

unless greatly varying load conditions are encountered

or if poor governor control develops after extended

usage. See Figure 3-25 for correct placement of

governor linkage (models may vary).

60 Hz generator sets are designed to operate at 60-63

Hz, 3600 rpm under full load and 3780 rpm under no

load. 50 Hz generator sets are designed to operate at

50--52.5 Hz, 3000 rpm under full load and 3150 rpm

under no load. Tocheck speed, use hand tachometer or

frequency meter. Use the following procedure to adjust

governor.

1. Loosen governor arm locking nut. See

Figure 3-24.

2. Move the governor arm end fully in the direction

shown (toward the electric choke solenoid) and

readjust governor screw. Tighten locking nut.

3. Start engine and run to reach operating

temperature.

4. Apply full load and turn engine speed adjustment

screw to 3600 rpm for 60 Hz generator set, 3000

rpm for 50 Hz set.

5. Check regulation by applying and removing full

load.

6. STOP generator set.

1

2

1. Mixture Screw

2. Idle Speed Screw

3. Governor Adjustment

1-829

3

Figure 3-24. Governor Adjustment

Carburetor

Governor

Adjustment

Screw

Throttle Rod/Spring

Governor Spring

Governor Cross Shaft

Governor Rod

Outer Hole

Hole Nearest

to Pivot Point

Pivot Point

Locknut

Figure 3-25. Governor Linkage