TP-5695 12/933-16 Scheduled Maintenance

Anticorrosion Zinc

An anticorrosion zinc anode is installed in the heat

exchanger to prevent electrolytic corrosion by seawater.

When different metals, such as iron and copper, are

placed in a highly conductive liquid (seawater), the iron

gradually rusts. The zinc has chemical properties which

cause the seawater to react to it rather than the engine

components.

The anticorrosion zinc anode should be checked every

100 hours or three months and replaced every 200

hours or yearly. Depending upon operating conditions

and seawater properties, the anticorrosion zinc anode

may have to be replaced more frequently. See

Figure 3-17 and use the following procedure.

TOTAL HOURS

00 000

1/10

10A

FUSE

STARTSTOP

BATT.

CHRG.

INPUT

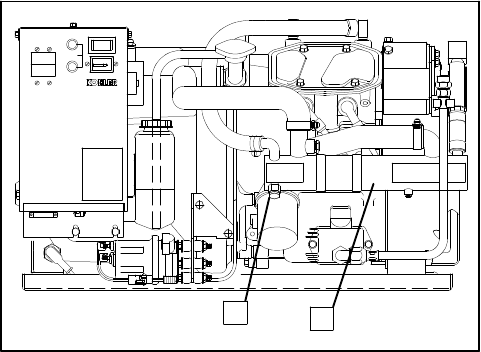

1. Heat Exchanger 2. Anticorrosion Zinc

2

1

258000-D

Figure 3-17. Removing Anticorrosion Zinc

1. With generator set cooled, drain the cooling

seawater system. Close seacock, remove

anticorrosion zinc anode from heat exchanger.

2. Use a wire brush to remove the loose corrosion on

the anticorrosion zinc anode. Replace the anode

when less than 50% of the 11/32 in. (9 mm) dia. by

9/16 in. (14 mm) long portion of zinc remains.

3. Clean threaded hole of heat exchanger and coat

threads of anticorrosion zinc anode with pipe

sealant (suitable for marine applications). Install

anticorrosion zinc anode into heat exchanger.

4. Open seacock. Start generator set and check for

leaks at the anticorrosion zinc anode location.

Check for seawater flow by observing water

discharge from exhaust outlet.