29

Section 4: Maintenance & Lubrication

5/09/08

RCR2596, RCR2510 and RCRM2510 Rotary Cutters 312-753M

Land Pride

Table of Contents

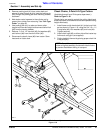

9. Check blade deflection. If deflection is greater than

3/4", remove blade bolt and reassemble as before

except include shim (#2) in the assembly. Select

shim thickness based on deflection. The greater the

deflection, the thicker the shim.

10. Once blade deflection is correct, replace used nut

with new locknut (#6) and torque to 450 ft-lbs.

11. If replacing dishpan (#4), nut on gearbox output shaft

should be torqued to 450 ft-lbs. minimum and cotter

pin installed in nut with legs securely bent around

nut.

Cutter Blade Assembly

Figure 4-2

3/4" maximum

blade deflection

when blade

bolts are tight

Land Pride Cutter Blade Parts

Item Part No. Part Description

318-586A BLADE BOLT KIT

(Includes items 1, 2, 5, & 6 below)

1 802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

2 312-075D BLADE SPACER 16 GA. (.060")

2 312-082D BLADE SPACER 18 GA. (.048")

2 312-089D BLADE SPACER 20 GA. (.036")

2 312-808D BLADE SPACER 24 GA. (.024")

3 --------- SEE LIST OF CUTTER BLADES BELOW

4 312-881H 27 x 10G OVAL DISHPAN WELDMENT

5 804-147C WASHER FLAT 1 HARD ASTMF436

6 803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

Land Pride List of Cutter Blades

Part No. Part Description

820-195C RCR2596 CUTTER BLADE 1/2 x 4 x 20 CCW

820-196C RCR2596 CUTTER BLADE 1/2 x 4 x 20 CW

820-137C RCR2510 CUTTER BLADE 1/2 x 4 x 25 CCW

820-112C RCR2510 CUTTER BLADE 1/2 x 4 x 25 CW

Optional Low Lift Cutter Blades

820-210C RCR2596 BLADE 1/2X4X20.5 LL CCW

820-211C RCR2596 BLADE 1/2X4X20.5 LL CW

820-193C RCR2510 BLADE 1/2X4X25 LL CCW

820-209C RCR2510 BLADE 1/2X4X25 LL CW

Driveline Protection

Cutter drive components are protected from shock loads

by a friction slip-clutch. The clutch must be capable of

slippage during operation to protect the gearbox,

driveline and other drive train parts.

Clutch Run-In

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity to remove

any oxidation that may have accumulated on friction

surfaces. To prevent driveline and gear box damage,

repeat “run-in” instructions at beginning of each season

and when moisture and/or condensation seizes inner

friction plates.

!

CAUTION!

Engage parking brake, disengage PTO, shut off tractor, and

remove key before making any of the following adjustments.

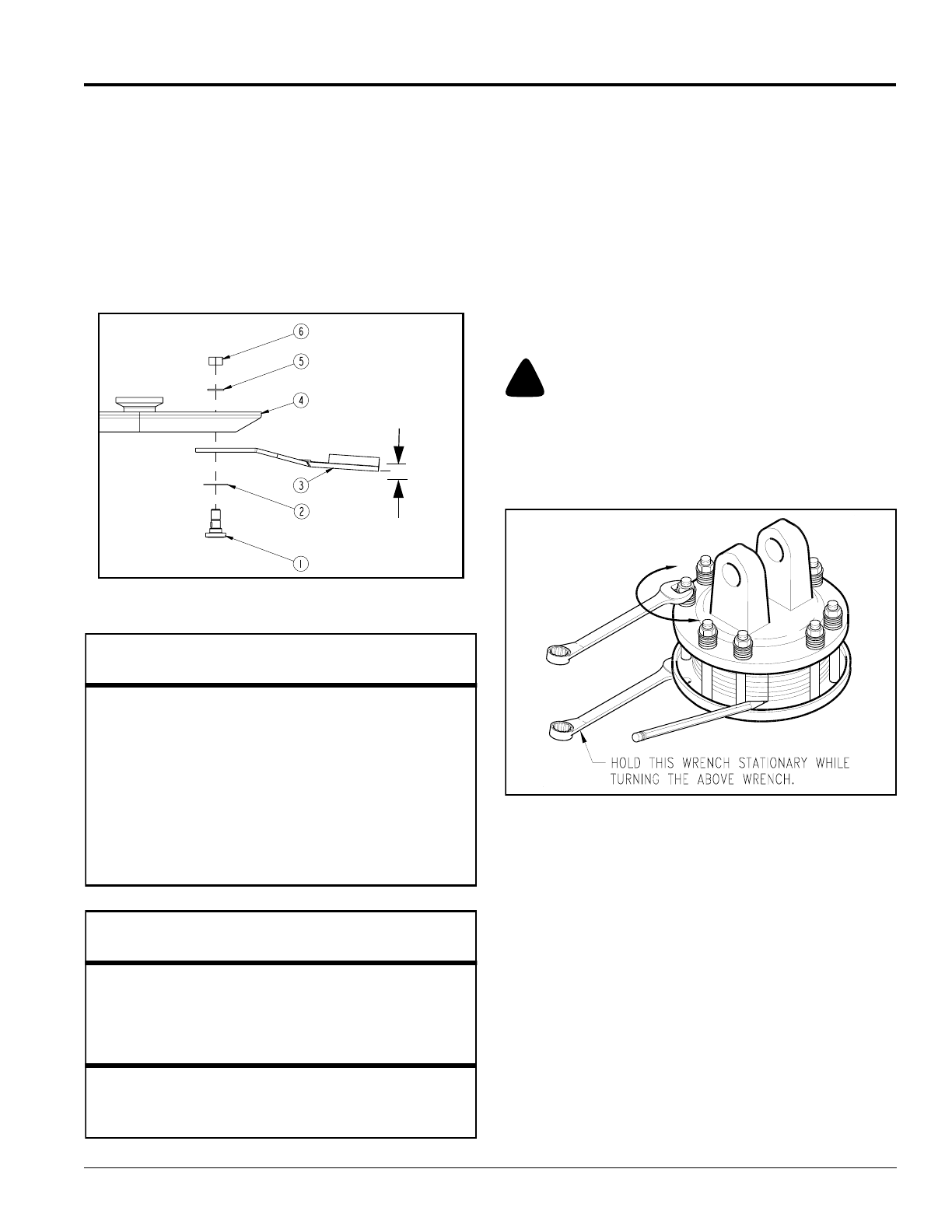

Refer to Refer to Figure 4-3:

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction discs.

Clutch

Figure 4-3

2. Carefully loosen each of the 8 spring retainer nuts on

the clutch housing a total of EXACTLY 2 revolutions.

It will be necessary to hold the hex end of the retainer

bolt in order to count the exact number of revolutions.

3. Start tractor and engage driveline for 2-3 seconds to

permit slippage of the clutch surfaces. Disengage

the PTO, then re-engage a second time for 2-3

seconds. Disengage the PTO, shut off tractor and

remove key. Wait for all components to stop before

dismounting from tractor.

4. Inspect clutch and ensure that scribed markings

made on the clutch plates have changed position.

Slippage has not occurred if any two marks on the

friction disc and plate are still aligned.

13693