Installing

IMPORTANT: Do not lose the shaft key. Key must be installed for

wheels to rotate and tractor to move.

NOTE: Rear wheels are installed with valves to the outside.

1. Install two washers (G), except on model D105, spacer (H), and shaft

key (F).

2. Install rear wheel, washer (E), snap ring (D) and plastic cap (C).

3. Safely remove jack stands and lower machine.

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this chart, see your

authorized dealer for service.

When you have checked all the possible causes listed and you are still

experiencing the problem, see your authorized dealer.

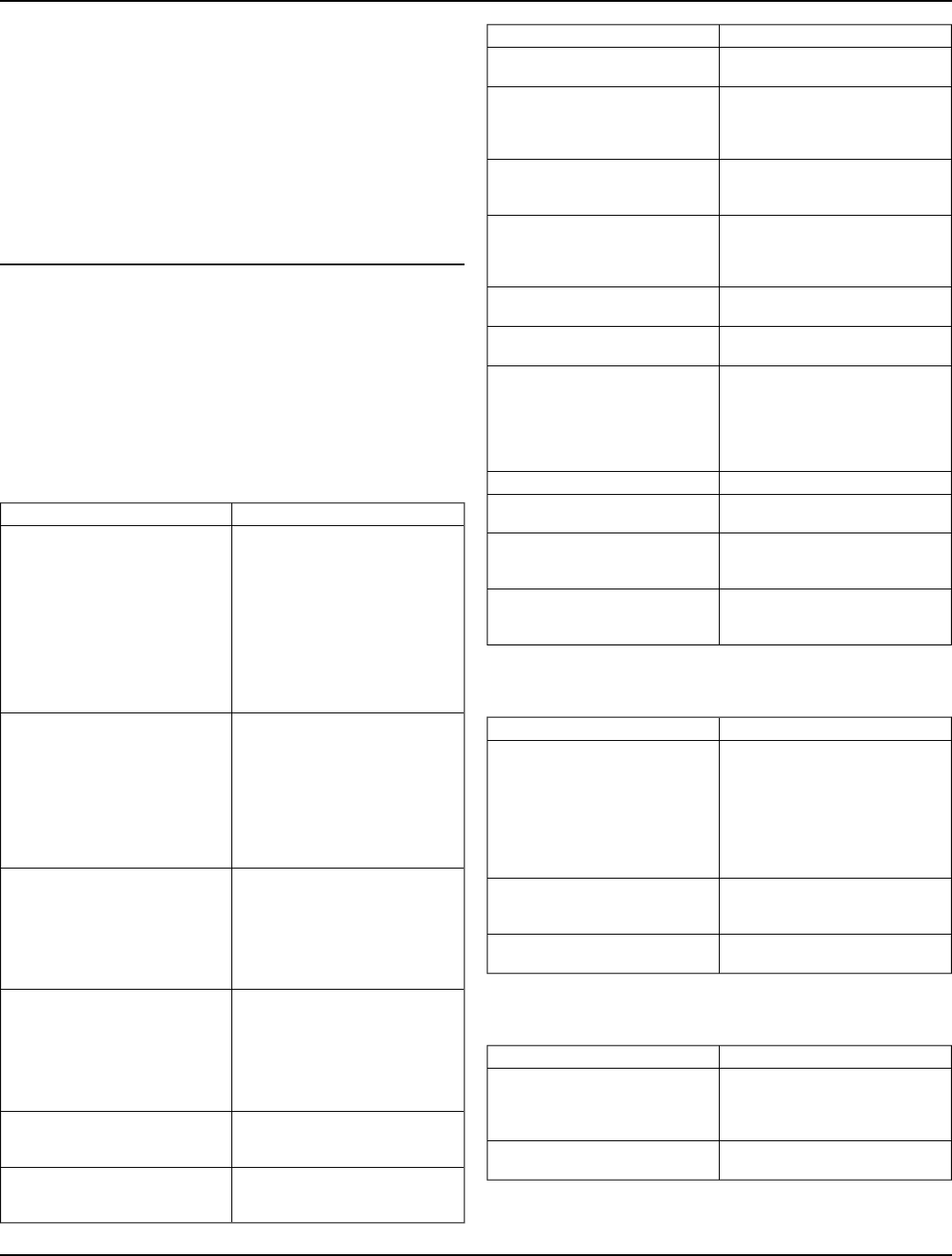

Engine

IF CHECK

Poor Engine Performance Dirt in fuel system or fuel is old. Replace fuel

with fresh stabilized fuel. Obtain fuel from

another supplier before suspecting machine

problems.Suppliersblend fuelsdifferentlyand

changing suppliers will generally solve any

performance problems.

Fuel blended with alcohol or ether may

contribute to performance problems by

causing gum and varnish deposits, especially

if fuel is stored for several weeks or more.

Obtain fresh fuel.

Engine Will Not Start Brake pedal not depressed.

Mower is engaged.

Spark plug wire is loose or disconnected.

Improper fuel.

Transmission is in reverse.

Plugged fuel lter.

Defective safety switch.

Electrical problem - See Electrical

Troubleshooting Section

Engine Is Hard To Start Carburetor is not adjusted properly or dirty.

Choke cable not adjusted properly.

Plugged fuel lter.

Faulty spark plug.

Stale or improper fuel.

Loose or corroded electrical connections.

Improper engine oil viscosity.

Engine Runs Unevenly Cooling ns plugged.

Loose electrical connections.

Choke or throttle cable sticking.

Fuel line or fuel lter plugged.

Stale or dirty fuel.

Improper fuel.

Air cleaner element plugged.

Engine Misses Under Load Faulty spark plug.

Stale or dirty fuel.

Plugged fuel lter.

Engine Vapor Locks Fuel tank vent plugged.

Dirt in fuel lter.

Cooling ns plugged.

IF CHECK

Loose hose connection at fuel lter or fuel

pump.

Engine Overheats Engine air intake screen plugged.

Cooling ns plugged.

Engine oil low or too high.

Engineoperated toolongat a slowidlespeed.

Engine Will Not Idle Spark plug not gapped correctly.

Faulty spark plug.

Operator raising off the seat.

Engine Knocks Stale or low octane fuel.

Engine overloaded.

Low engine speed.

Oil level low.

Engine Stops Or Misses When Operating On

Hillsides

Fuel tank less than half full of fuel.

Operator raising off of the seat.

Engine Backres Faulty spark plug.

Operator raising off of the seat.

Engine Loses Power Engine overheating.

Too much oil in engine.

Dirty air cleaner.

Faulty spark plug.

Travel speed is too fast for conditions.

Improper fuel.

Excessive Fuel Consumption Choke is not fully open.

Black Exhaust Smoke Air lter is dirty or oil soaked.

Choke partially engaged.

Engine Stops WhenREVERSE Foot Pedal Is

Depressed And Attachment Is Engaged

(Hydrostatic)

Normal condition. (See Using Reverse

Implement Option in the OPERATING

section.)

Engine Stops When Automatic Shift Lever Is

Moved To The R (REVERSE) Position and

Attachment Is Engaged (Automatic)

Normal condition. (See Using Reverse

Implement Option in the OPERATING

section.)

Electrical

IF CHECK

Starter Does Not Work Or Will Not Turn

Engine

Brake pedal is not depressed.

Mower is engaged.

Battery terminals are corroded.

Battery not charged.

Transmission is in reverse.

Blown fuse.

Fusible Link in starting circuit is blown - See

your authorized dealer

Battery Will Not Charge Dead cell in the battery.

Battery cables and terminals are dirty.

Low engine speed or excessive idling.

Lights Do Not Work Light plug disconnected.

Loose or burned out bulb.

Tractor

IF CHECK

Tractor Vibrates Too Much Or Rattles

Excessively

Attachment drive belts worn or damaged.

Traction drive belt damaged or worn.

Dirt on drive sheaves.

Blades bent or out of balance.

Tractor Will Not Move With Engine Running Parking brake locked.

Bypass rod is pulled out.

Troubleshooting

50