• Always maintain the correct tire pressure. Do not inate the tires

above the recommended pressure. Never weld or heat a wheel and

tire assembly. The heat can cause an increase in air pressure resulting

in a tire explosion. Welding can structurally weaken or deform the

wheel.

• When inating tires, use a clip-on chuck and extension hose long

enough to allow you to stand to one side and NOT in front of or over

the tire assembly.

• Check tires for low pressure, cuts, bubbles, damaged rims or missing

lug bolts and nuts.

Checking Wheel Hardware

• A serious accident could occur causing serious injury if wheel

hardware is not tight.

• Check wheel hardware tightness often during the rst 100 hours of

operation.

• Wheel hardware must be tightened to specied torque using the

proper procedure anytime it is loosened.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake uid, and

batteries, can harm the environment and people:

• Do not use beverage containers for waste uids - someone may drink

from them.

• See your local Recycling Center or authorized dealer to learn how to

recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides specic details on

chemical products: physical and health hazards, safety procedures,

and emergency response techniques. The seller of the chemical

products used with your machine is responsible for providing the

MSDS for that product.

Machine Cleanout

Prevent Fires

• Besides routine maintenance, one of the best ways to keep your John

Deere equipment running efciently and to reduce re risk is to

regularly remove debris buildup from the machine.

• Please review these recommendations with all operators. See your

John Deere dealer with questions.

• Always follow all safety procedures posted on the machine and in this

operator manual. Before carrying out any inspection or cleaning,

always shut off engine, set parking brake and remove ignition key.

• After operating, allow machine to cool in an open area before cleaning

or storing. Do not park machine near ammable materials such as

wood, cloth or chemicals.

• Empty any grasscatcher bags or containers completely before storing.

• Frequency of these inspections and cleaning will vary depending on a

number of factors including operating conditions, machine

conguration, operating speeds and weather conditions particularly

dry, hot and windy conditions. When you are operating in these

conditions, inspect and clean these areas frequently throughout the

day.

• Wind direction, terrain type and moisture content of surrounding

vegetation can effect where and how much debris accumulates.

• Debris can accumulate anywhere on the machine, especially on

horizontal surfaces.

• Keeping engine area clean will provide the greatest impact on re

prevention. Other areas requiring regular inspection and cleaning

include behind wheel rims, wire harness, hose/line routings, mowing

attachments, etc. Compressed air, leaf blowers or high pressured

water can assist keeping these areas clean.

• Excess lubrication or fuel/oil leaks or spills on the machine can also

serve as collection sites for debris. Prompt machine repair and oil/fuel

cleanup will minimize the potential for debris collection and reduced

cooling throughout machine life.

• Bearing failures or overheating can result in a re. To reduce this risk,

always follow the instructions in the machine operator’s manual

regarding lubrication intervals and locations. Washing the machine

while warm may also reduce bearing life and increase potential for

premature bearing failure.

• Always shut off fuel when storing or transporting machine, if the

machine has a fuel shutoff.

Cleanout Areas

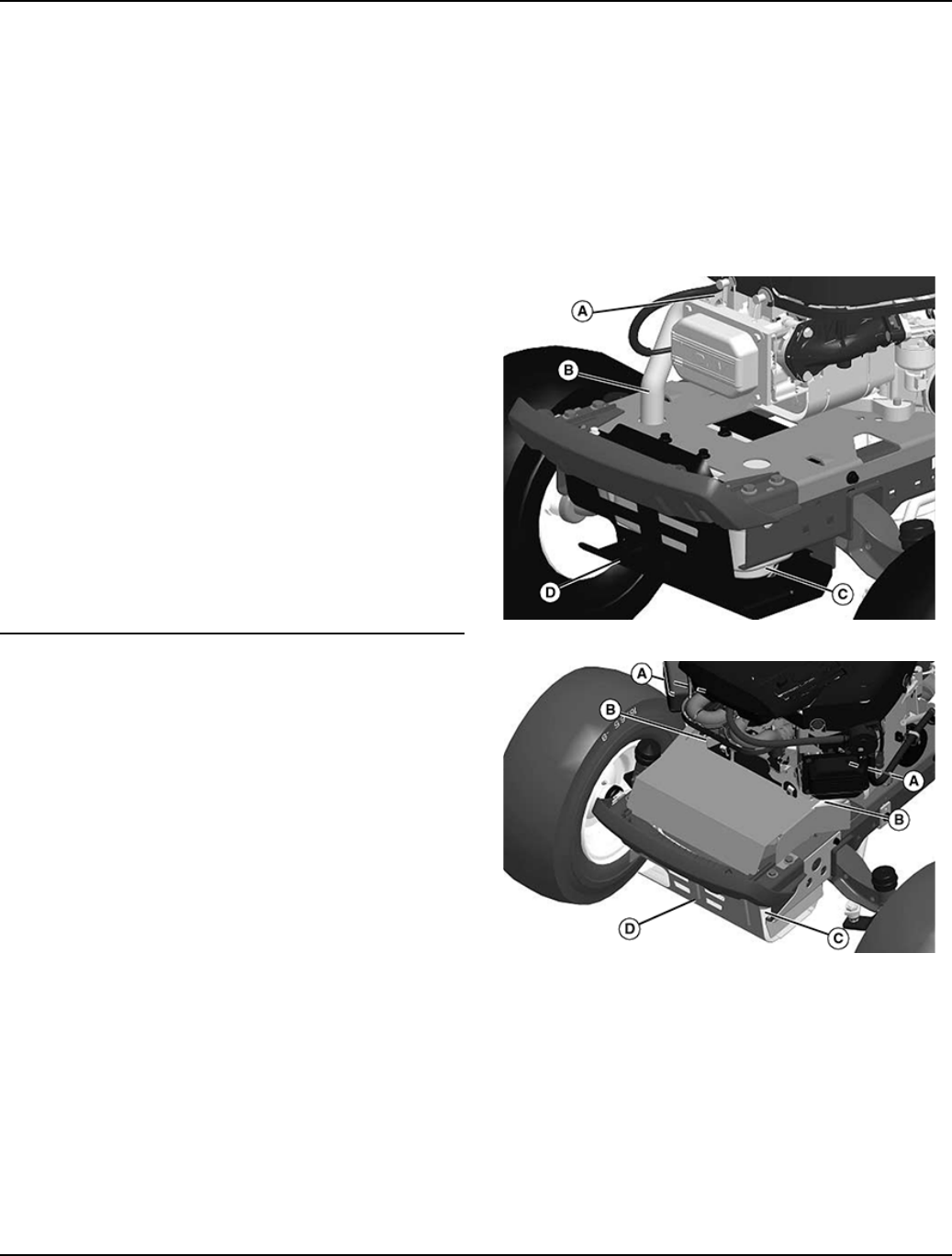

Primary areas that must be inspected and cleaned on the machine

include (See Safety Label Section):

GXAL41967—UN—04MAR13

Single cylinder shown

GXAL41968—UN—04MAR13

Twin cylinder shown

1. Exhaust manifold (A), mufer pipe (B), mufer (C) and mufer shield

(D).

Machine Cleanout

16