4. Remove fuel tank cap slowly to allow any pressure built up in tank to

escape.

5. Fill fuel tank only to bottom of ller neck. Do not overll.

6. Install fuel tank cap.

• Gas models: Turn cap until clicks.

Lifting Machine

1. Park machine safely. (See Parking Safely in the SAFETY section.)

CAUTION: The machine can fall or slip from an unsafe lifting

device or supports.

• UUssee aa ssaaffee lliiffttiinngg ddeevviiccee rraatteedd ffoorr tthhee llooaadd ttoo bbee lliifftteedd..

• LLoowweerr mmaacchhiinnee oonnttoo jjaacckk ssttaannddss oorr ootthheerr ssttaabbllee ssuuppppoorrttss

aanndd bblloocckk wwhheeeellss bbeeffoorree sseerrvviicciinngg..

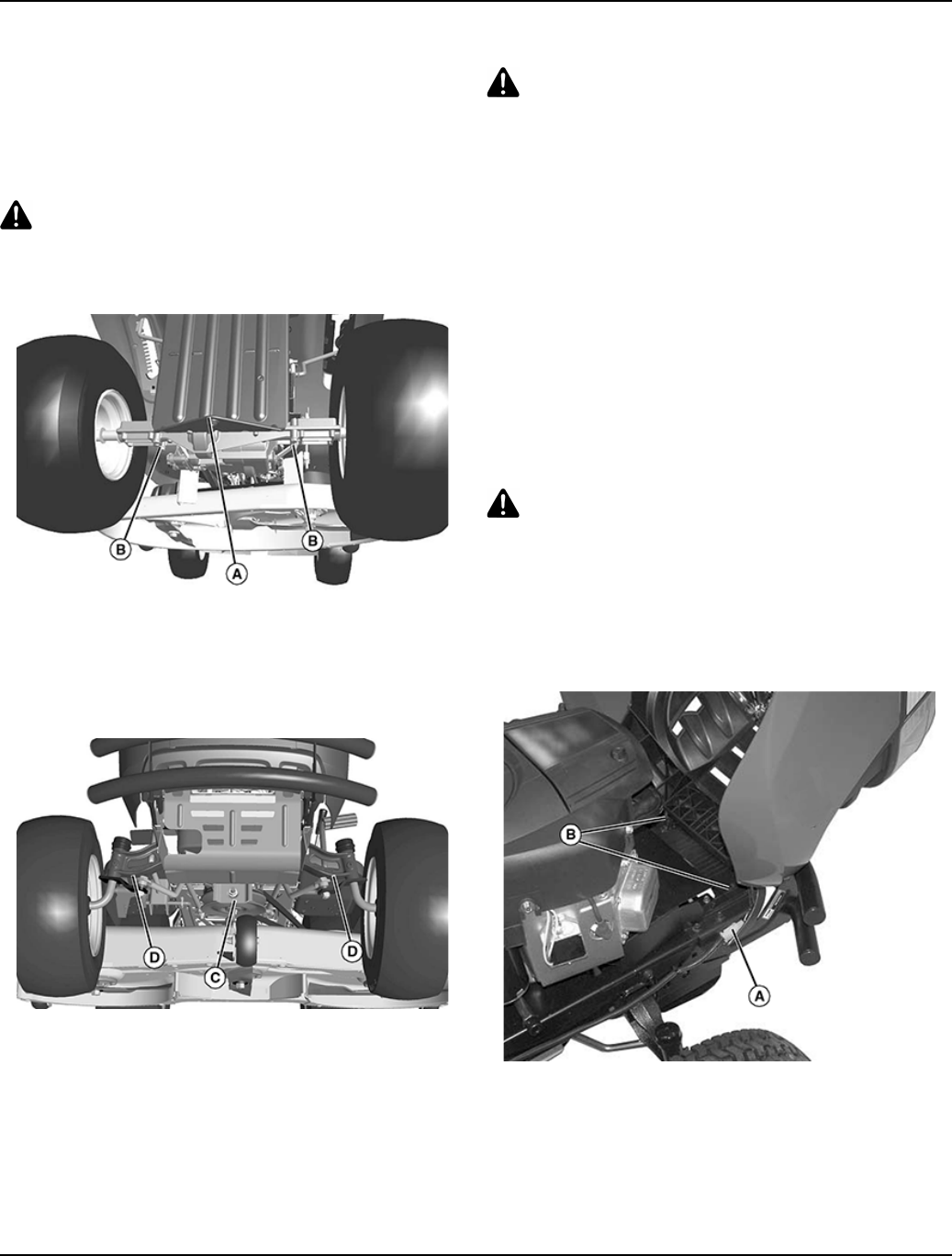

GXAL42048—UN—04MAR13

Hydrostatic transmission model shown

2. Safely lift rear of machine at machine frame point (A). Place jack

stands or other stable supports onto transaxle locations (B) where

mounting bolts for frame come through.

3. If only lifting rear of machine, block front wheels remaining on ground

to avoid movement of machine.

GXAL42049—UN—04MAR13

4. Safely lift front of machine at machine frame point (C). Place jack

stands or other stable supports under frame on each side at location

(B).

5. If only lifting front of machine, block rear wheels remaining on ground

to avoid movement of machine.

6. To lower machine, lift front and/or rear of machine, and remove jack

stands or supports. Lower machine.

Checking Tire Pressure

CAUTION: Explosive separation of tire and rim parts is

possible when they are serviced incorrectly:

• DDoo nnoott aatttteemmpptt ttoo mmoouunntt aattiirree wwiitthhoouutt tthheepprrooppeerr eeqquuiippmmeenntt

aanndd eexxppeerriieennccee ttoo ppeerrffoorrmm tthhee jjoobb..

• DDoo nnoott iinnaattee tthhee ttiirreess aabboovvee tthhee rreeccoommmmeennddeedd pprreessssuurree..

• DDoo nnoott wweelldd oorr hheeaatt aa wwhheeeell aanndd ttiirree aasssseemmbbllyy.. HHeeaatt ccaann

ccaauussee aann iinnccrreeaassee iinn aaiirr pprreessssuurree rreessuullttiinngg iinn aann eexxpplloossiioonn..

WWeellddiinngg ccaann ssttrruuccttuurraallllyy wweeaakkeenn oorr ddeeffoorrmm tthhee wwhheeeell..

• DDoo nnoott ssttaanndd iinn ffrroonntt oorr oovveerr tthhee ttiirree aasssseemmbbllyy wwhheenn

iinnaattiinngg.. UUssee aa cclliipp--oonn cchhuucckk aanndd eexxtteennssiioonn hhoossee lloonngg

eennoouugghh ttoo aallllooww yyoouu ttoo ssttaanndd ttoo oonnee ssiiddee..

1. Check tires for damage.

NOTE: Refer to the SPECIFICATIONS section for tire pressures or check

the side of the tire.

2. Check tire pressure with an accurate lower pressure gauge.

3. Add or remove air, if necessary.

Removing and Installing Hood

Removing

CAUTION: Touching hot surfaces can burn skin. The engine,

components, and uids will be hot if the engine has been

running. Allow the engine to cool before servicing or working

near the engine and components.

IMPORTANT: Do not operate machine with hood open. Hood must

be closed for proper engine cooling and exhaust.

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Let engine cool.

PY19053—UN—07AUG13

3. Open hood.

4. Disconnect wiring harness (A).

5. Apply pressure to “John” on left side of hood and slowly lower hood.

Left side pivot should release after rotating closed approximately 45

degrees. Once left side pivot releases, slide out right side pivot.

Lower hood slightly and lift hood from brackets (B).

Service Miscellaneous

47