Section 6

DIAGNOSTIC TESTS

Page 51

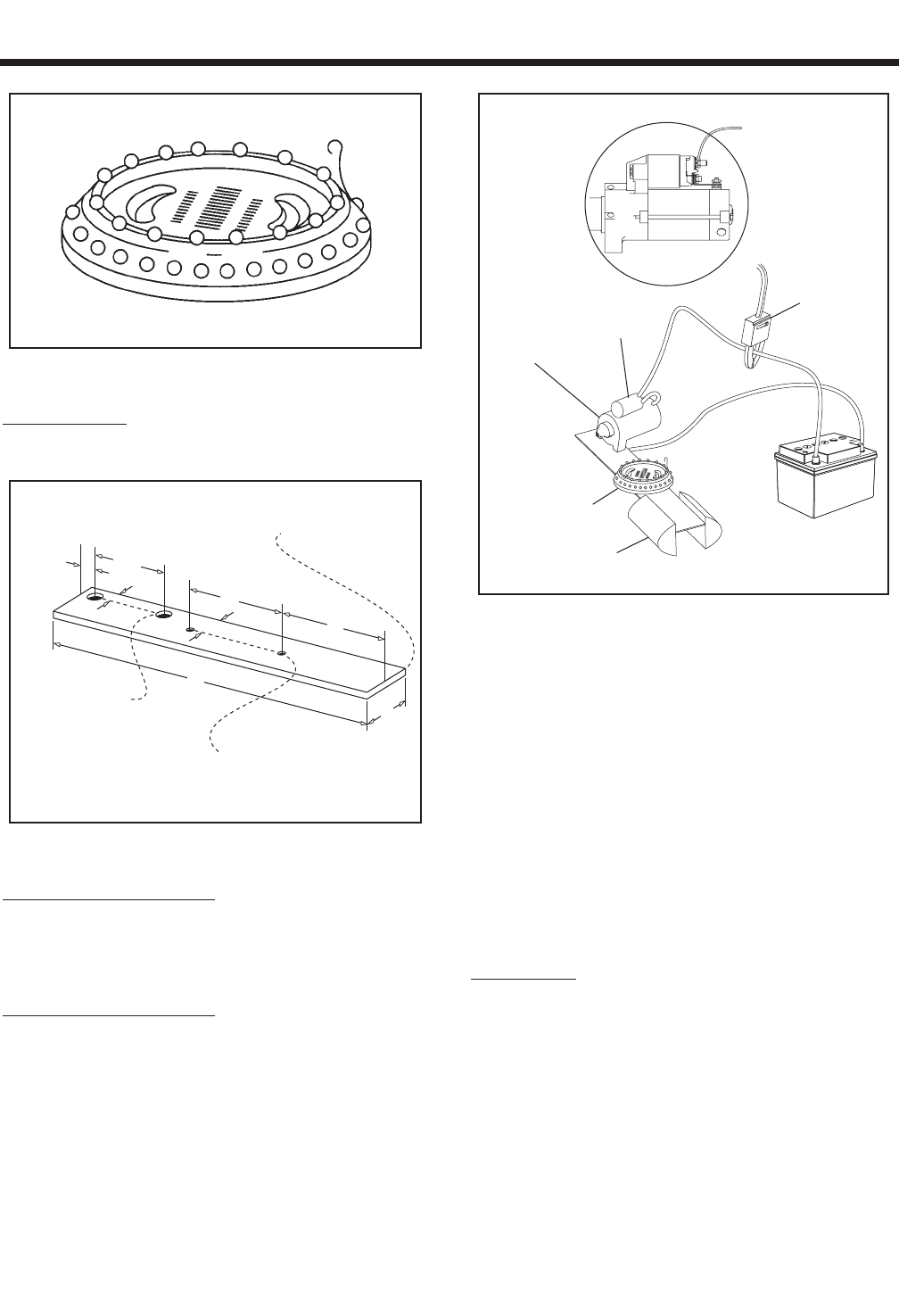

Figure 6-32. – Tachometer

TEST BRACKET:

A starter motor test bracket may be made as shown

in Figure 6-33.

METAL STOCK

1/4" THICK STEEL

12"

1.0"

4"

2"

2.625"

3.5"

0.5"

0.5"

DRILL TWO HOLES — 1/2"

FOR STARTER

MOUNTING BRACKET

DRILL TWO HOLES — 1/2"

FOR MOUNTING TACHOMETER

TAP FOR 1/4-20 NC SCREWS

Figure 6-33. – Test Bracket Dimensions

REMOVE STARTER MOTOR:

It is recommended that the Starter Motor be removed

from the engine when testing Starter Motor perfor-

mance. Assemble starter to test bracket and clamp

test bracket in vise (Figure 6-34).

TESTING STARTER MOTOR:

1. A fully charged 12 volt battery is required.

2. Connect jumper cables and clamp-on ammeter as shown in

Figure 6-34.

3. With the Starter Motor activated (jump the terminal on the

Starter Contactor to battery voltage), note the reading on the

clamp-on ammeter and on the tachometer (rpm).

STARTER

CONTACTOR

STARTER

MOTOR

TACHOMETER

12 VOLT

BATTERY

CLAMP ON

AMP METER

VISE

Figure 6-34 – Testing Starter Motor Performance

Note: Take the reading after the ammeter and

tachometer are stabilized, approximately 2-4

seconds.

4. A starter motor in good condition will be within the following

specifications:

Minimum rpm 4500

Maximum Amps 50

Note: Nominal amp draw of starter in generator is

60 amps.

TEST 26 - TEST STARTER CONTACTOR

RELAY (SCR)

PROCEDURE:

1. Set voltmeter to measure DC voltage.

2. Remove Wire 15 from the Starter Contactor Relay (SCR).

Connect the positive meter test lead to Wire 15 previous

-

ly removed. Connect the negative meter test lead to frame

Ground. 12 VDC should be measured. Reconnect Wire 15 to

the SCR. If 12 VDC is NOT measured on Wire 15 Stop Testing

and repair or replace Wire 15 between the Fuse (F1) and the

SCR.

3. Remove Wire 13 from the Starter Contactor Relay (SCR).

Connect the positive meter test lead to Wire 13 previous

-

ly removed. Connect the negative meter test lead to frame