Groundsmaster 4500--D/4700--D Hydraulic SystemPage 4 -- 71

Procedure for Gear Pump Flow

Test

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

1. Make sure hydraulic oil is at normal operating tem-

perature by operatingthe machinefor approximately ten

(10) minutes. Make sure the hydraulic reservoir is full.

2. Park machine on a level surface with the cutting

decks lowered and off. Make sure engine is off and the

parking brake is applied.

3. Raise and support operator seat to gain access to

gear pump.

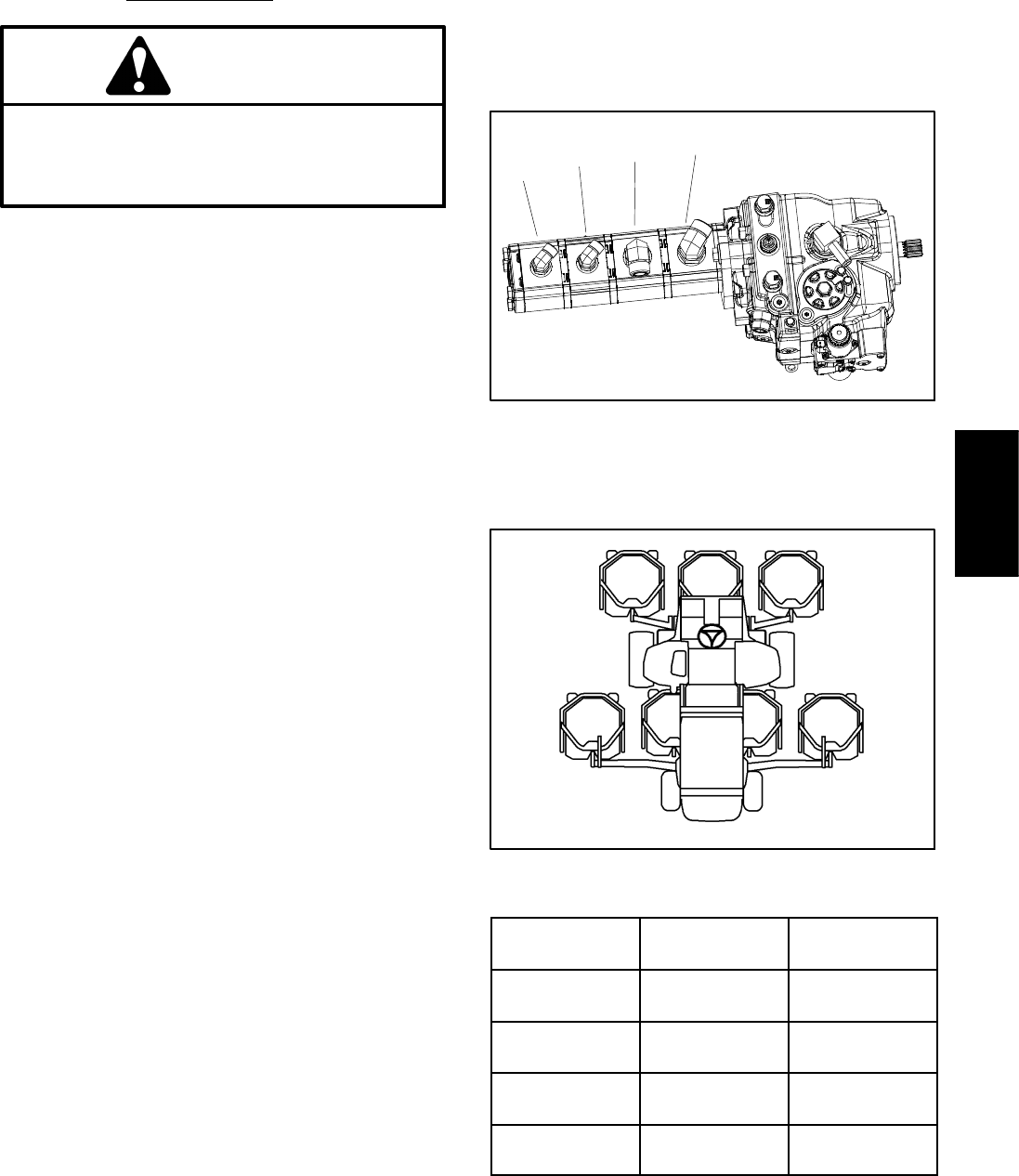

4. Determine which gear pump section is to be tested.

Disconnect hydraulic hose from fitting in gear pump sec-

tion that is to be tested (Fig. 57).

5. Install tester (flow and pressure) in series with the

disconnected hose and hydraulic fitting in gear pump

section.

6. Make sure the flow control valve on tester is fully

open.

7. Start engine and increase engine speed to high idle

speed. Do not engage the cutting decks.

IMPORTANT: Do not fully restrict oil flow through

tester. In this test, the flow tester is positioned be-

fore the relief valve. Pump damage can occur if the

oil f low is f ully restricted.

8. Watch pressure gauge carefully while slowly closing

the flow control valve until 1000 PSI (69 bar) is obtained.

Verify with the InfoCenter display that the engine is still

running at the correct high idle speed.

NOTE: If engine speed drops during testing, pump flow

will decrease and flow test results will be inaccurate.

9. Normal flow indication for the four (4) gear pump s ec-

tionsislistedinFigure59.

10.Shut off engine and record test results.

11.If apressure of 1000 PSI (69bar) cannotbe obtained

or flow was less than the minimum flow listed in Figure

59, check for restriction in the pump intake line. If line is

not restricted, consider that the tested gear pump sec-

tion is worn or damaged.

12.After testing is completed, disconnect flow tester

from hydraulic hose and fittingin gear pump section. Re-

connect hose to the pump fitting.

13.Lower and secure operator seat.

1. First gear pump section (de cks 2, 3, 5 and 7)

2. 2

nd

gear pump section (decks 1, 4 and 6)

3. 3

rd

gear pump section (steering, lift/lower and charge)

4. 4

th

gear pump section (engine cooling fan)

Figure 57

2

3

1

4

Figure 58

#4

#1

#5

#7

(GM4700)

#6

(GM4700)

#3#2

CUTTING DECK LOCATIONS

Deck

PUMP

SECTION

NORMAL

FLOW

MINIMUM

FLOW

FIRST

SECTION

11 GPM

(41.6 LPM)

9GPM

(34 LPM)

SECOND

SECTION

11 GPM

(41.6 LPM)

9GPM

(34 LPM)

THIRD

SECTION

6GPM

(22.7 LPM)

4.8 GPM

(18 LPM)

FOURTH

SECTION

6GPM

(22.7 LPM)

4.8 GPM

(18 LPM)

Figure 59

Hydraulic

System