Engine Operation - Except 4.5L “270” Engines

OURGP11,0000075 –19–27JUL06–3/4

RG11616 –UN–24OCT01

Engine Oil Filter

A—Engine Oil Filter

4. During the first 20 hours, avoid prolonged periods of

engine idling or sustained maximum load operation. If

engine will idle longer than 5 minutes, stop engine.

5. Before the first 100 hours (maximum), change engine

oil and replace engine oil filter (A). (See CHANGING

ENGINE OIL AND REPLACING FILTER in Lubrication

and Maintenance/500 Hour/12 Month Section.) Fill

crankcase with seasonal viscosity grade oil. (See

DIESEL ENGINE OIL, in Fuels, Lubricants, and

Coolant Section.)

NOTE: Some increase in oil consumption may be

expected when low viscosity oils are used. Check

oil levels more frequently.

If air temperature is below -10

°

C (14

°

F), use an

engine block heater.

OURGP11,0000075 –19–27JUL06–4/4

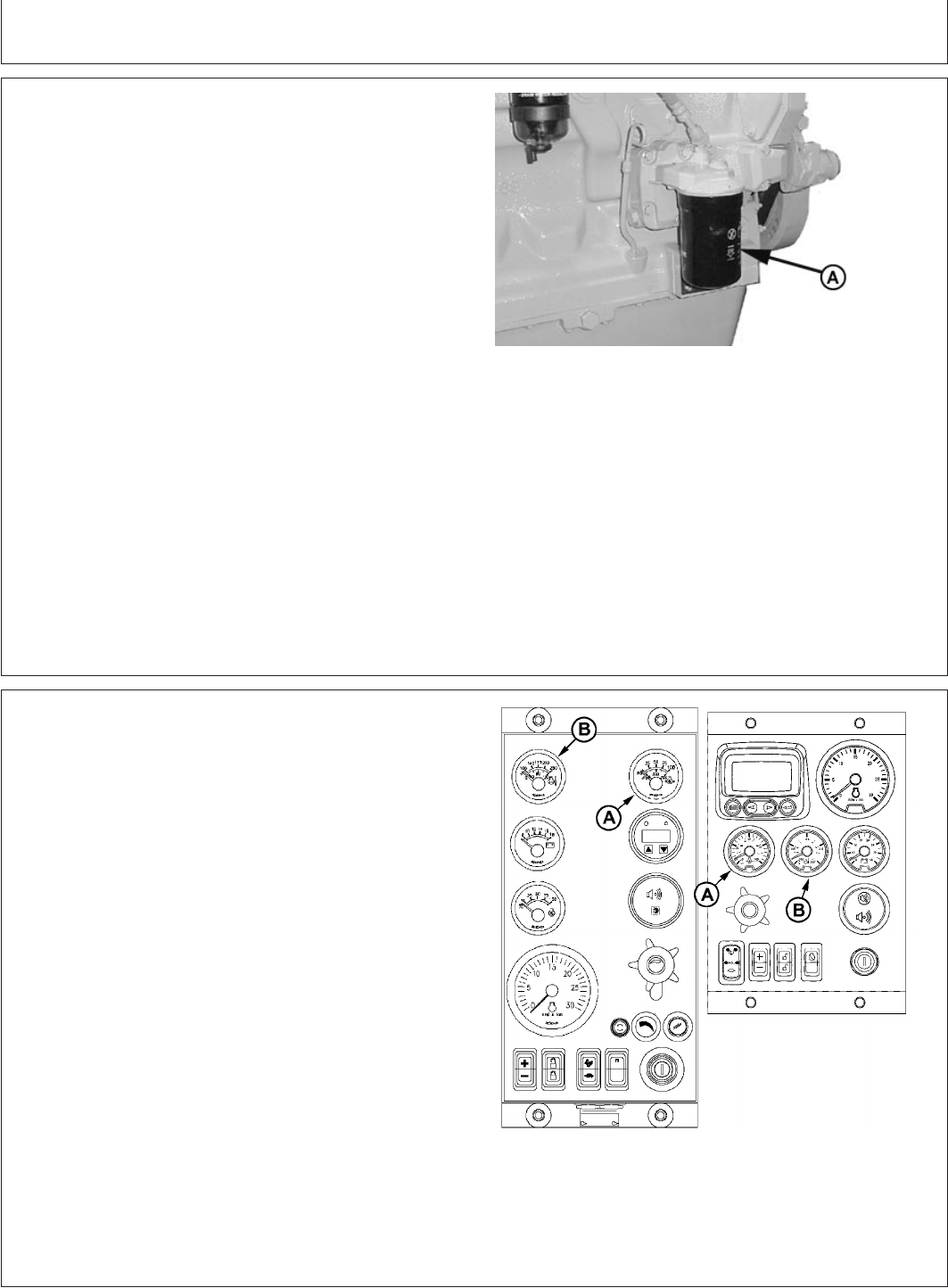

RG13281 –UN–30OCT03

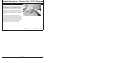

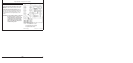

Watch Coolant Temperature and Oil Pressure On Earlier Panel

(Left) or Later Panel (Right)

A—Engine Oil Pressure Gauge

B—Engine Coolant Temperature Gauge

6. Watch oil pressure gauge (A). Pressure at slow idle

should be at least 103 kPa (1.03 bar) (15 psi) once

engine is warmed up and shouild rise to at least 241

kPa (2.41 bar) (35 psi) at rated speed under full load.

7. Watch coolant temperature gauge (B) closely. If

coolant temperature rises above 112°C (234°F), reduce

load on engine. Unless temperature drops quickly, stop

the engine and determine the cause before resuming

operation.

NOTE: When the coolant temperature gauge reads

approximately 115

°

C (239

°

F), the engine will

shutdown automatically, if equipped with safety

controls.

8. Check poly-vee belt for proper alignment and seating

in pulley grooves.

19-3

080706

PN=101