SSeeccttiioonn 77

DDIIAAGGNNOOSSTTIICC TTEESSTTSS

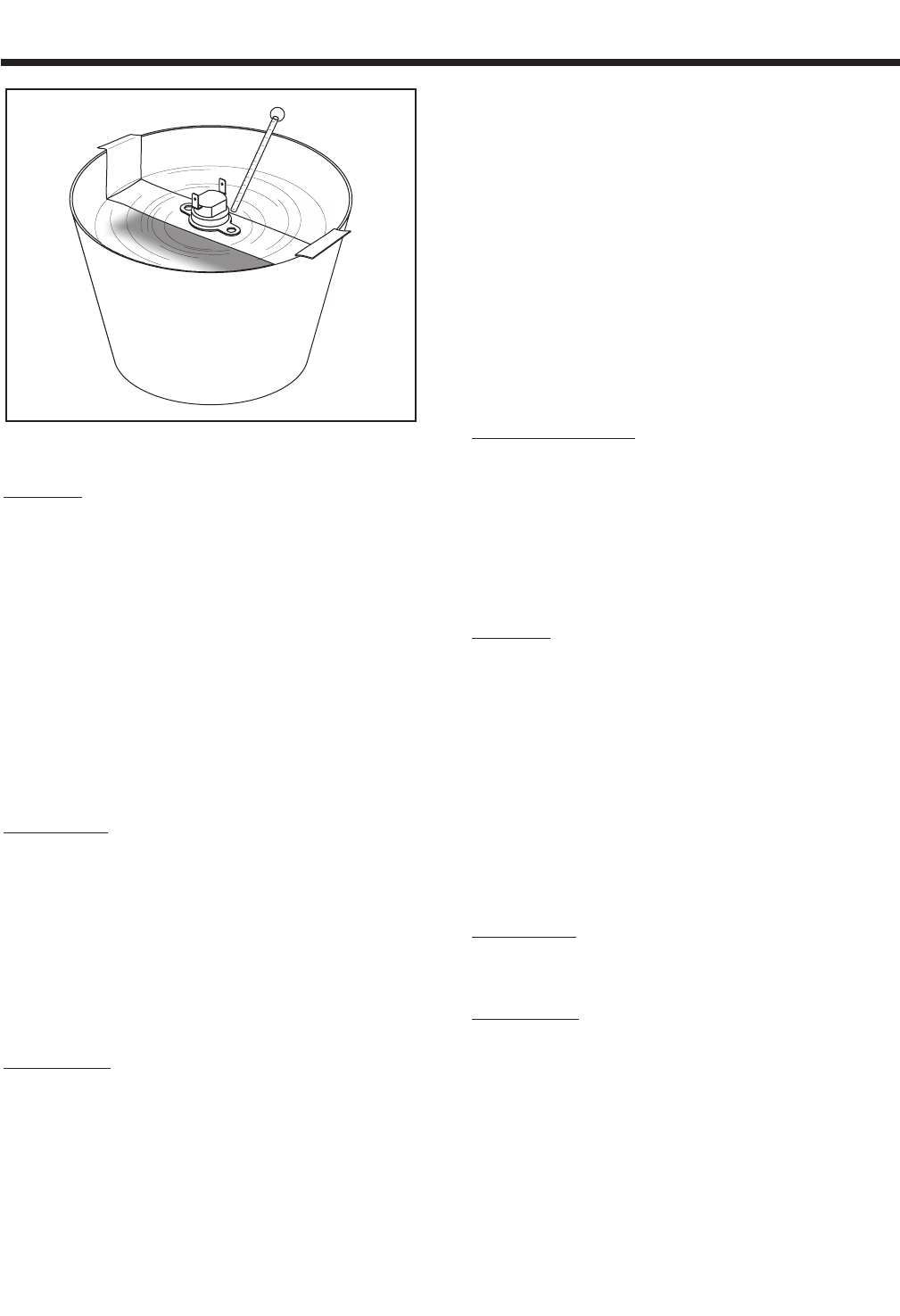

Figure 7-48. – Testing Oil Temperature Switch

RESULTS:

1. If the Oil Temperature Switch fails Step 3 or Step 4, replace the

Oil Temperature Switch.

2. If the Oil Temperature Switch is good, an overheat condition

may be occurring. Verify that the installation of the generator is

within specified tolerances. The generator must receive the

proper amount of incoming air, and also be able to exhaust the

cooling air with NO RESTRICTIONS. Check to be sure that the

exhaust pipe is not under the air intake. Refer to the Owner’s

and Installation Manual for proper installation specifications. If

installation is correct, go to Test 24.

TEST 41 - TEST CHOKE HEATER

DISCUSSION:

The Choke Heater is a sensitive heating element

wrapped around a temperature sensitive Bi-Metal

strip. The BI-METAL HEATER ASSEMBLY positions

the Choke Plate during startup. Once running, the Bi-

Metal Heater Assembly will also allow the Choke

Plate to fully open. Power for the heater element is

supplied from Wire 14 to assist the Bi-Metal Heater

Assembly in opening the Choke Plate after starting.

Failure of the Choke Plate to open will cause an

excessively rich fuel-air mixture and engine perfor-

mance will suffer.

PROCEDURE:

1. Verify that the Choke Plate on the carburetor is mechanically

free to move and is not binding. If the engine runs rough, check

the operation of the BI-METAL HEATER ASSEMBLY. Allow

the engine to run for five minutes, then inspect the choke posi-

tion. The Bi-Metal strip should have been heated by the Choke

Heater and should have expanded to allow the Choke Plate to

open fully.

2. If the Choke Plate did not open in Step 1, check the Choke

Heater. Set the VOM to measure DC voltage. Disconnect

Connector 1 at the Choke Assembly. Connect the positive (+)

meter test lead to Wire 14 (Connector 1, Pin 3) going to the

control panel. Connect the negative (-) meter test lead to a

clean frame ground. Set the Start-Stop Switch to “START.”

Battery voltage should be measured (see Figure 7-43 on

Page 63).

3. If battery voltage was not measured in Step 2, set the VOM to

measure resistance. Disconnect Connector 1 at the Choke

Assembly. Connect one meter test lead to Wire 14 (Connector

1, Pin 3) going to the control panel. Connect the other meter

test lead to the 4-tab Terminal for Wire 14 in the control panel.

“Continuity” should be measured.

SHORT TO GROUND:

Set the VOM to measure resistance. Connect one

meter test lead to Wire 14 (Connector 1, Pin 3) going to

the Bi-Metal Heater Assembly. Connect the other meter

test lead to the exposed steel portion of the Bi-Metal

Heater Assembly. Approximately 37 ohms (±20%)

should be measured. (Current draw of the Bi-Metal

Heater Assembly at nominal voltage is approximately

340 milliamps or 0.340 amps). If “Continuity” is present

the Bi-Metal Heater Assembly has a short to ground.

RESULTS:

1. If Choke Plate is binding in Step 1, repair or replace binding

Choke Plate. If Bi-Metal Heater Assembly tests good, go to

Test 35.

2. If continuity was not measured in Step 3, repair or replace Wire

14 between the 4-tab Terminal and Connector 1.

3. If the resistance value is incorrect in the Short to Ground step,

or the Bi-Metal Heater Assembly does not function with voltage

present, replace the Bi-Metal Heater Assembly.

TEST 42 - CHECK LPG FUEL SOLENOID

DISCUSSION:

If the LPG Fuel Solenoid (FS) fails to open, fuel will

not be available to the engine and it will not start.

PROCEDURE:

1. Place one hand on the top of the LPG Fuel Solenoid. Activate

the Fuel Prime Switch. You should be able to feel as well as

hear the solenoid energize. If solenoid energizes discontinue

testing.

2. Set VOM to measure resistance. Disconnect Wire 0 from the

LPG Fuel Solenoid. Connect one meter test lead to Wire 0.

Connect the other test lead to a clean frame ground.

“Continuity” should be measured. Reconnect Wire 0 to LPG

shut off valve.

Page 66